|

Ebullated Bed Reactor

Ebullated bed reactors are a type of fluidized bed reactor that utilizes ebullition, or bubbling, to achieve appropriate distribution of reactants and catalysts. The ebullated-bed technology utilizes a three-phase reactor (liquid, vapor, and catalyst), and is most applicable for exothermic reactions and for feedstocks which are difficult to process in fixed-bed or plug flow reactors due to high levels of contaminants. Ebullated bed reactors offer high-quality, continuous mixing of liquid and catalyst particles. The advantages of a good back-mixed bed include excellent temperature control and, by reducing bed plugging and channeling, low and constant pressure drops. Therefore, ebullated bed reactors have the characteristics of stirred reactor type operation with a fluidized catalyst. Operation The catalyst used for the ebullated bed is typically a 0.8-mm diameter extrudate, and is held in a fluidized state through the upward lift of liquid reactants and gas. The liquid and gas enter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluidized Bed Reactor

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid (gas or liquid) is passed through a solid granular material (usually a catalyst) at high enough speeds to suspend the solid and cause it to behave as though it were a fluid. This process, known as fluidization, imparts many important advantages to an FBR. As a result, FBRs are used for many industrial applications. Basic principles The solid substrate material (the catalytic material upon which chemical species react) in the fluidized bed reactor is typically supported by a porous plate, known as a distributor.Howard, J. R. (1989). ''Fluidized Bed Technology: Principles and Applications.'' New York, NY: Adam Higler. The fluid is then forced through the distributor up through the solid material. At lower fluid velocities, the solids remain in place as the fluid passes through the voids in the material. This is know ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reagent

In chemistry, a reagent ( ) or analytical reagent is a substance or compound added to a system to cause a chemical reaction, or test if one occurs. The terms ''reactant'' and ''reagent'' are often used interchangeably, but reactant specifies a substance ''consumed'' in the course of a chemical reaction. ''Solvents'', though involved in the reaction mechanism, are usually not called reactants. Similarly, ''catalysts'' are not consumed by the reaction, so they are not reactants. In biochemistry, especially in connection with enzyme-catalyzed reactions, the reactants are commonly called substrates. Definitions Organic chemistry In organic chemistry, the term "reagent" denotes a chemical ingredient (a compound or mixture, typically of inorganic or small organic molecules) introduced to cause the desired transformation of an organic substance. Examples include the Collins reagent, Fenton's reagent, and Grignard reagents. Analytical chemistry In analytical chemistry, a reagent ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Catalyst

Catalysis () is the process of increasing the rate of a chemical reaction by adding a substance known as a catalyst (). Catalysts are not consumed in the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quickly, very small amounts of catalyst often suffice; mixing, surface area, and temperature are important factors in reaction rate. Catalysts generally react with one or more reactants to form intermediates that subsequently give the final reaction product, in the process of regenerating the catalyst. Catalysis may be classified as either homogeneous, whose components are dispersed in the same phase (usually gaseous or liquid) as the reactant, or heterogeneous, whose components are not in the same phase. Enzymes and other biocatalysts are often considered as a third category. Catalysis is ubiquitous in chemical industry of all kinds. Estimates are that 90% of all commercially produced chemical products involve catalysts at some s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exothermic

In thermodynamics, an exothermic process () is a thermodynamic process or reaction that releases energy from the system to its surroundings, usually in the form of heat, but also in a form of light (e.g. a spark, flame, or flash), electricity (e.g. a battery), or sound (e.g. explosion heard when burning hydrogen). The term ''exothermic'' was first coined by 19th-century French chemist Marcellin Berthelot. The opposite of an exothermic process is an endothermic process, one that absorbs energy usually in the form of heat. The concept is frequently applied in the physical sciences to chemical reactions where chemical bond energy is converted to thermal energy (heat). Two types of chemical reactions Exothermic and endothermic describe two types of chemical reactions or systems found in nature, as follows: Exothermic After an exothermic reaction, more energy has been released to the surroundings than was absorbed to initiate and maintain the reaction. An example would be the burn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plug Flow Reactor

The plug flow reactor model (PFR, sometimes called continuous tubular reactor, CTR, or piston flow reactors) is a model used to describe chemical reactions in continuous, flowing systems of cylindrical geometry. The PFR model is used to predict the behavior of chemical reactors of such design, so that key reactor variables, such as the dimensions of the reactor, can be estimated. Fluid going through a PFR may be modeled as flowing through the reactor as a series of infinitely thin coherent "plugs", each with a uniform composition, traveling in the axial direction of the reactor, with each plug having a different composition from the ones before and after it. The key assumption is that as a plug flows through a PFR, the fluid is perfectly mixed in the radial direction but not in the axial direction (forwards or backwards). Each plug of differential volume is considered as a separate entity, effectively an infinitesimally small continuous stirred tank reactor, limiting to zero volu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Drop

Pressure drop is defined as the difference in total pressure between two points of a fluid carrying network. A pressure drop occurs when frictional forces, caused by the resistance to flow, act on a fluid as it flows through the tube. The main determinants of resistance to fluid flow are fluid velocity through the pipe and fluid viscosity. Pressure drop increases proportionally to the frictional shear forces within the piping network. A piping network containing a high relative roughness rating as well as many pipe fittings and joints, tube convergence, divergence, turns, surface roughness, and other physical properties will affect the pressure drop. High flow velocities and/or high fluid viscosities result in a larger pressure drop across a section of pipe or a valve or elbow. Low velocity will result in lower or no pressure drop. The fluid may also be biphasic as in pneumatic conveying with a gas and a solid, in this case, the friction of the solid must also be taken into consi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plenum Chamber

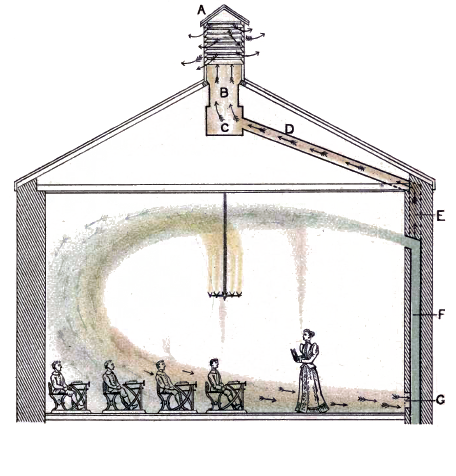

A plenum chamber is a pressurised housing containing a fluid (typically air) at positive pressure. One of its functions is to equalise pressure for more even distribution, compensating for irregular supply or demand. It is typically relatively large in volume and thus has relatively low velocity compared to the system's other components. In wind tunnels, rockets, and many flow applications, it is a chamber upstream on the fluid flow where the fluid initially resides (approximately at rest). It can also work as an acoustic silencer. Examples of plenum chambers include those used with: * Superchargers * Hovercraft * Corliss steam engines * Raised floors and false ceilings in equipment rooms * Some organs (to supplement the bellows) * A number of aerophones, such as the bag of bagpipes and the ''slow air chamber'' of the Native American flute * Plenum chamber anesthetic vaporizers * Rocket motor combustion chambers, which may have a section near the nozzle that is free of the prop ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Centrifugal Pump

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits. Common uses include water, sewage, agriculture, petroleum, and petrochemical pumping. Centrifugal pumps are often chosen for their high flow rate capabilities, abrasive solution compatibility, mixing potential, as well as their relatively simple engineering. A centrifugal fan is commonly used to implement an air handling unit or vacuum cleaner. The reverse function of the centrifugal pump is a water turbine converting potential energy of water pressure into mechanical rotational energy. His ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Catalysis

Catalysis () is the process of increasing the rate of a chemical reaction by adding a substance known as a catalyst (). Catalysts are not consumed in the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quickly, very small amounts of catalyst often suffice; mixing, surface area, and temperature are important factors in reaction rate. Catalysts generally react with one or more reactants to form intermediates that subsequently give the final reaction product, in the process of regenerating the catalyst. Catalysis may be classified as either homogeneous, whose components are dispersed in the same phase (usually gaseous or liquid) as the reactant, or heterogeneous, whose components are not in the same phase. Enzymes and other biocatalysts are often considered as a third category. Catalysis is ubiquitous in chemical industry of all kinds. Estimates are that 90% of all commercially produced chemical products involve catalysts at some s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Delayed Coker

A delayed coker is a type of coker whose process consists of heating a residual oil feed to its thermal cracking temperature in a furnace with multiple parallel passes. This cracks the heavy, long chain hydrocarbon molecules of the residual oil into coker gas oil and petroleum coke. Delayed coking is one of the unit processes used in many oil refineries. The adjacent photograph depicts a delayed coking unit with 4 drums. However, larger units have tandem pairs of drums, some with as many as 8 drums, each of which may have diameters of up to 10 meters and overall heights of up to 43 meters. The yield of coke from the delayed coking process ranges from about 18 to 30 percent by weight of the feedstock residual oil, depending on the composition of the feedstock and the operating variables. Many refineries worldwide produce as much as 2,000 to 3,000 tons per day of petroleum coke and some produce even more. Schematic flow diagram and description The flow diagram and description in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Reactors

A chemical reactor is an enclosed volume in which a chemical reaction takes place. In chemical engineering, it is generally understood to be a process vessel used to carry out a chemical reaction, which is one of the classic unit operations in chemical process analysis. The design of a chemical reactor deals with multiple aspects of chemical engineering. Chemical engineers design reactors to maximize net present value for the given reaction. Designers ensure that the reaction proceeds with the highest efficiency towards the desired output product, producing the highest yield of product while requiring the least amount of money to purchase and operate. Normal operating expenses include energy input, energy removal, raw material costs, labor, etc. Energy changes can come in the form of heating or cooling, pumping to increase pressure, frictional pressure loss or agitation.Chemical reaction engineering is the branch of chemical engineering which deals with chemical reactors and their ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |