|

District Heating Substation

image:Wärmeübergabestation 300 kW.jpg, A district heating substation in a residential neighborhood with a thermal capacity of 300 kW. Two components of the heat meter are visible: the metering electronics unit on the right (white/blue box), and the ultrasonic flow meter in the center (bronze tube). A district heating substation is a component in a district heating system that connects the main network to a building's own heating system. The station normally has one or more of the following parts: * Heat exchanger A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct conta ... - to split primary and secondary side of the system * Control valve - to regulate the flow through the heat exchanger * Differential pressure controller - to balance the network and improve working conditions of control ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

District Heating

District heating (also known as heat networks or teleheating) is a system for distributing heat generated in a centralized location through a system of insulated pipes for residential and commercial heating requirements such as space heating and water heating. The heat is often obtained from a cogeneration plant burning fossil fuels or biomass, but heat-only boiler stations, geothermal heating, heat pumps and central solar heating are also used, as well as heat waste from factories and nuclear power electricity generation. District heating plants can provide higher efficiencies and better pollution control than localized boilers. According to some research, district heating with combined heat and power (CHPDH) is the cheapest method of cutting carbon emissions, and has one of the lowest carbon footprints of all fossil generation plants. Fifth-generation district heat networks do not use combustion on-site and have zero emissions of CO and NO on-site; they employ heat transfer u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heating System

A heating system is a mechanism for maintaining temperatures at an acceptable level; by using thermal energy within a home, office, or other dwelling. Often part of an HVAC (heating, ventilation, air conditioning) system. A heating system may be a central heating system or distributed. See also * HVAC * Boiler * Radiator * Solar energy * Heating plant A heating plant, also called a physical plant, or steam plant, generates thermal energy in the form of steam for use in district heating applications. Unlike combined heat and power installations which produce thermal energy as a by-product ... Heating {{Energy-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant. Flow arrangement Image:Heat_exc_1-1.svg, Fig. 1: Shell and tube heat exchanger, single pass (1–1 parallel f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Control Valve

A control valve is a valve used to control fluid flow by varying the size of the flow passage as directed by a signal from a controller. This enables the direct control of flow rate and the consequential control of process quantities such as pressure, temperature, and liquid level. In automatic control terminology, a control valve is termed a "final control element". Operation The opening or closing of automatic control valves is usually done by electrical, hydraulic or pneumatic actuators. Normally with a modulating valve, which can be set to any position between fully open and fully closed, valve positioners are used to ensure the valve attains the desired degree of opening. Air-actuated valves are commonly used because of their simplicity, as they only require a compressed air supply, whereas electrically operated valves require additional cabling and switch gear, and hydraulically actuated valves required high pressure supply and return lines for the hydraulic fluid. The p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant. Flow arrangement Image:Heat_exc_1-1.svg, Fig. 1: Shell and tube heat exchanger, single pass (1–1 parallel f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Meter

A heat meter attached to a heat exchanger in a District heating substation in a residential neighborhood. Right in white-blue: the calculator; in the center in bronze: the ultrasonic flow meter A heat meter or energy meter is a device which measures thermal energy provided by a heater, source or delivered to a heat sink, sink, by measuring the flow rate of the Coolant, heat transfer fluid and the change in its temperature ( Psychrometrics, ΔT) between the outflow and return legs of the system. It is typically used in industrial plants for measuring boiler output and heat taken by process, and for district heating systems to measure the heat delivered to consumers. It can be used to measure the heat output of say a heating boiler, or the cooling output from a chiller unit. In Europe heat meters have to comply with the measuring instruments directive MID Annex VI MI-004 if the meters are used for custody transfer. Elements A heat meter consists of # a fluid flow meter - typic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Energy Consumption

Energy consumption is the amount of energy used. Biology In the body, energy consumption is part of energy homeostasis. It derived from food energy. Energy consumption in the body is a product of the basal metabolic rate and the physical activity level. The physical activity level are defined for a non-pregnancy, pregnant, non-lactation, lactating adult as that person's total energy expenditure (TEE) in a 24-hour period, divided by his or her basal metabolic rate (BMR): :\text=\frac Demographics Topics related to energy consumption in a demographic sense are: * World energy supply and consumption * Domestic energy consumption * Electric energy consumption Effects of energy consumption * Environmental impact of the energy industry ** Global warming * White's law Reduction of energy consumption * Energy conservation, the practice of decreasing the quantity of energy used * Efficient energy use See also * Efficient energy use, Energy efficiency * Energy efficiency in transpor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manometer

Pressure measurement is the measurement of an applied force by a fluid (liquid or gas) on a surface. Pressure is typically measured in units of force per unit of surface area. Many techniques have been developed for the measurement of pressure and vacuum. Instruments used to measure and display pressure mechanically are called pressure gauges, vacuum gauges or compound gauges (vacuum & pressure). The widely used Bourdon gauge is a mechanical device, which both measures and indicates and is probably the best known type of gauge. A vacuum gauge is used to measure pressures lower than the ambient atmospheric pressure, which is set as the zero point, in negative values (for instance, −1 bar or −760 mmHg equals total vacuum). Most gauges measure pressure relative to atmospheric pressure as the zero point, so this form of reading is simply referred to as "gauge pressure". However, anything greater than total vacuum is technically a form of pressure. For very low press ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

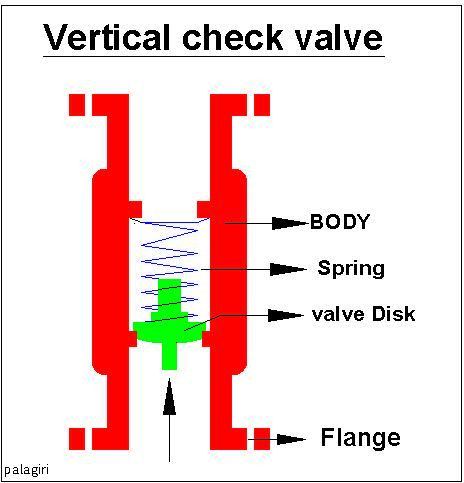

Non-return Valve

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction. Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. Check valves are often part of common household items. Although they are available in a wide range of sizes and costs, check valves generally are very small, simple, and inexpensive. Check valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. The bodies (external shells) of most check valves are made of plastic or metal. An important concept in check valves is the cracking pressure which is the minimum differential upstream pressure between inlet and outlet at which the valve will operate. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |