|

Directional Solidification

Directional solidification (DS) and progressive solidification are types of solidification within castings. Directional solidification is solidification that occurs from farthest end of the casting and works its way towards the sprue. Progressive solidification, also known as parallel solidification,. is solidification that starts at the walls of the casting and progresses perpendicularly from that surface.. Theory - Most metals and alloys shrink as the material changes from a liquid state to a solid state. Therefore, if liquid material is not available to compensate for this shrinkage a '' shrinkage defect'' forms. When progressive solidification dominates over directional solidification a shrinkage defect will form. The geometrical shape of the mold cavity has a direct effect on progressive and directional solidification. At the end of tunnel-type geometries, divergent heat flow occurs, which causes that area of the casting to cool faster than surrounding areas; this is cal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Directional Solidification

Directional solidification (DS) and progressive solidification are types of solidification within castings. Directional solidification is solidification that occurs from farthest end of the casting and works its way towards the sprue. Progressive solidification, also known as parallel solidification,. is solidification that starts at the walls of the casting and progresses perpendicularly from that surface.. Theory - Most metals and alloys shrink as the material changes from a liquid state to a solid state. Therefore, if liquid material is not available to compensate for this shrinkage a '' shrinkage defect'' forms. When progressive solidification dominates over directional solidification a shrinkage defect will form. The geometrical shape of the mold cavity has a direct effect on progressive and directional solidification. At the end of tunnel-type geometries, divergent heat flow occurs, which causes that area of the casting to cool faster than surrounding areas; this is cal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

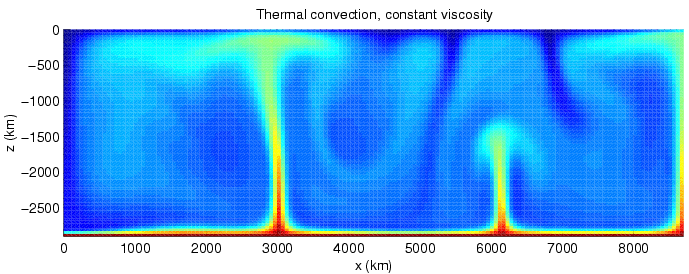

Heat Flow

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, thermal convection, thermal radiation, and transfer of energy by phase changes. Engineers also consider the transfer of mass of differing chemical species (mass transfer in the form of advection), either cold or hot, to achieve heat transfer. While these mechanisms have distinct characteristics, they often occur simultaneously in the same system. Heat conduction, also called diffusion, is the direct microscopic exchanges of kinetic energy of particles (such as molecules) or quasiparticles (such as lattice waves) through the boundary between two systems. When an object is at a different temperature from another body or its surroundings, heat flows so that the body and the surroundings reach the same temperature, at which point they are in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

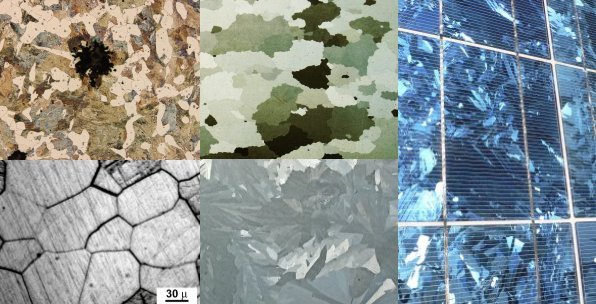

Silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic table: carbon is above it; and germanium, tin, lead, and flerovium are below it. It is relatively unreactive. Because of its high chemical affinity for oxygen, it was not until 1823 that Jöns Jakob Berzelius was first able to prepare it and characterize it in pure form. Its oxides form a family of anions known as silicates. Its melting and boiling points of 1414 °C and 3265 °C, respectively, are the second highest among all the metalloids and nonmetals, being surpassed only by boron. Silicon is the eighth most common element in the universe by mass, but very rarely occurs as the pure element in the Earth's crust. It is widely distributed in space in cosmic dusts, planetoids, and planets as various forms of silico ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polycrystal

A crystallite is a small or even microscopic crystal which forms, for example, during the cooling of many materials. Crystallites are also referred to as grains. Bacillite is a type of crystallite. It is rodlike with parallel longulites. Structure The orientation of crystallites can be random with no preferred direction, called random texture, or directed, possibly due to growth and processing conditions. While the structure of a ( single) crystal is highly ordered and its lattice is continuous and unbroken, amorphous materials, such as glass and many polymers, are non-crystalline and do not display any structures, as their constituents are not arranged in an ordered manner. Polycrystalline structures and paracrystalline phases are in-between these two extremes. Polycrystalline materials, or polycrystals, are solids that are composed of many crystallites of varying size and orientation. Most materials are polycrystalline, made of a large number crystallites held together by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Zone Melting

Zone melting (or zone refining, or floating-zone method, or floating-zone technique) is a group of similar methods of purifying crystals, in which a narrow region of a crystal is melted, and this molten zone is moved along the crystal. The molten region melts impure solid at its forward edge and leaves a wake of purer material solidified behind it as it moves through the ingot. The impurities concentrate in the melt, and are moved to one end of the ingot. Zone refining was invented by John Desmond Bernal and further developed by William G. Pfann William G. Pfann (1966) ''Zone Melting'', 2nd edition, John Wiley & Sons in Bell Labs as a method to prepare high purity materials, mainly semiconductors, for manufacturing transistors. Its first commercial use was in germanium, refined to one atom of impurity per ten billion,”Zone melting”, entry in ''The World Book Encyclopedia'', Volume 21, W-X-Y-Z, 1973, page 501. but the process can be extended to virtually any solute–solvent ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scheil Equation

In metallurgy, the Scheil-Gulliver equation (or Scheil equation) describes solute redistribution during solidification of an alloy. Assumptions Four key assumptions in Scheil analysis enable determination of phases present in a cast part. These assumptions are: # No diffusion occurs in solid phases once they are formed (\ D_S = 0 ) # Infinitely fast diffusion occurs in the liquid at all temperatures by virtue of a high diffusion coefficient, thermal convection, Marangoni convection, etc. (\ D_L = \infty) # Equilibrium exists at the solid-liquid interface, and so compositions from the phase diagram are valid # Solidus and liquidus are straight segments The fourth condition (straight solidus/liquidus segments) may be relaxed when numerical techniques are used, such as those used in CALPHAD software packages, though these calculations rely on calculated equilibrium phase diagrams. Calculated diagrams may include odd artifacts (i.e. retrograde solubility) that influence ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Partition Coefficient

In the physical sciences, a partition coefficient (''P'') or distribution coefficient (''D'') is the ratio of concentrations of a compound in a mixture of two immiscible solvents at equilibrium. This ratio is therefore a comparison of the solubilities of the solute in these two liquids. The partition coefficient generally refers to the concentration ratio of un-ionized species of compound, whereas the distribution coefficient refers to the concentration ratio of all species of the compound (ionized plus un-ionized). In the chemical and pharmaceutical sciences, both phases usually are solvents. Most commonly, one of the solvents is water, while the second is hydrophobic, such as 1-octanol. Hence the partition coefficient measures how hydrophilic ("water-loving") or hydrophobic ("water-fearing") a chemical substance is. Partition coefficients are useful in estimating the distribution of drugs within the body. Hydrophobic drugs with high octanol-water partition coefficients are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Riser (casting)

A riser, also known as a feeder, is a reservoir built into a metal casting mold to prevent cavities due to shrinkage. Most metals are less dense as a liquid than as a solid so castings shrink upon cooling, which can leave a void at the last point to solidify. Risers prevent this by providing molten metal to the casting as it solidifies, so that the cavity forms in the riser and not the casting.. Risers are not effective on materials that have a large freezing range, because directional solidification is not possible. They are also not needed for casting processes that utilized pressure to fill the mold cavity. Theory Risers are only effective if three conditions are met: the riser cools after the casting, the riser has enough material to compensate for the casting shrinkage, and the casting directionally solidifies towards the riser. For the riser to cool after the casting the riser must cool more slowly than the casting. Chvorinov's rule briefly states that the slowest cooli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chill (casting)

A chill is an object used to promote solidification in a specific portion of a metal casting mold. Normally the metal in the mould cools at a certain rate relative to thickness of the casting. When the geometry of the molding cavity prevents directional solidification from occurring naturally, a chill can be strategically placed to help promote it. There are two types of chills: ''internal'' and ''external'' chills.. Types ''Internal'' chills are pieces of metal that are placed inside the molding cavity. When the cavity is filled, part of the chill will melt and ultimately become part of the casting, thus the chill must be the same material as the casting. Note that internal chills will absorb both heat capacity and heat of fusion energy. ''External'' chills are masses of material that have a high heat capacity and thermal conductivity. They are placed on the edge of the molding cavity, and effectively become part of the wall of the molding cavity. This type of chill can be used t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting Solidification Conditions

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various ''time setting'' materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC. History Throughout history, metal casting has been used to make tools, weapons, and religious objects. Metal casting history an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Progressive Solidification

Directional solidification (DS) and progressive solidification are types of solidification within castings. Directional solidification is solidification that occurs from farthest end of the casting and works its way towards the sprue. Progressive solidification, also known as parallel solidification,. is solidification that starts at the walls of the casting and progresses perpendicularly from that surface.. Theory - Most metals and alloys shrink as the material changes from a liquid state to a solid state. Therefore, if liquid material is not available to compensate for this shrinkage a '' shrinkage defect'' forms. When progressive solidification dominates over directional solidification a shrinkage defect will form. The geometrical shape of the mold cavity has a direct effect on progressive and directional solidification. At the end of tunnel-type geometries, divergent heat flow occurs, which causes that area of the casting to cool faster than surrounding areas; this is ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting Defect

A casting defect is an undesired irregularity in a metal casting process. Some defects can be tolerated while others can be repaired, otherwise they must be eliminated. They are broken down into five main categories: ''gas porosity'', ''shrinkage defects'', ''mould material defects'', ''pouring metal defects'', and ''metallurgical defects''. Terminology The terms "defect" and "" refer to two specific and separate things in castings. Defects are defined as conditions in a casting that must be corrected or removed, or the casting must be rejected. Discontinuities, also known as "imperfections", are defined as "interruptions in the physical continuity of the casting". Therefore, if the casting is less than perfect, but still useful and in tolerance, the imperfections should be deemed "discontinuities". Types There are many types of defects which result from many different causes. Some of the solutions to certain defects can be the cause for another type of defect. The following def ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |