|

Duralumin

Duralumin (also called duraluminum, duraluminium, duralum, dural(l)ium, or dural) is a trade name for one of the earliest types of age-hardenable aluminium alloys. The term is a combination of '' Dürener'' and ''aluminium''. Its use as a trade name is obsolete. Today the term mainly refers to aluminium–copper alloys, designated as the 2000 series by the international alloy designation system (IADS), as with 2014 and 2024 alloys used in airframe fabrication. History Duralumin was developed by the German metallurgist Alfred Wilm at Dürener Metallwerke AG. In 1903, Wilm discovered that after quenching, an aluminium alloy containing 4% copper would harden when left at room temperature for several days. Further improvements led to the introduction of duralumin in 1909. The name is mainly used in pop-science to describe all Al-Cu alloys system, or '2000' series, as designated through the international alloy designation system originally created in 1970 by the Aluminum A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

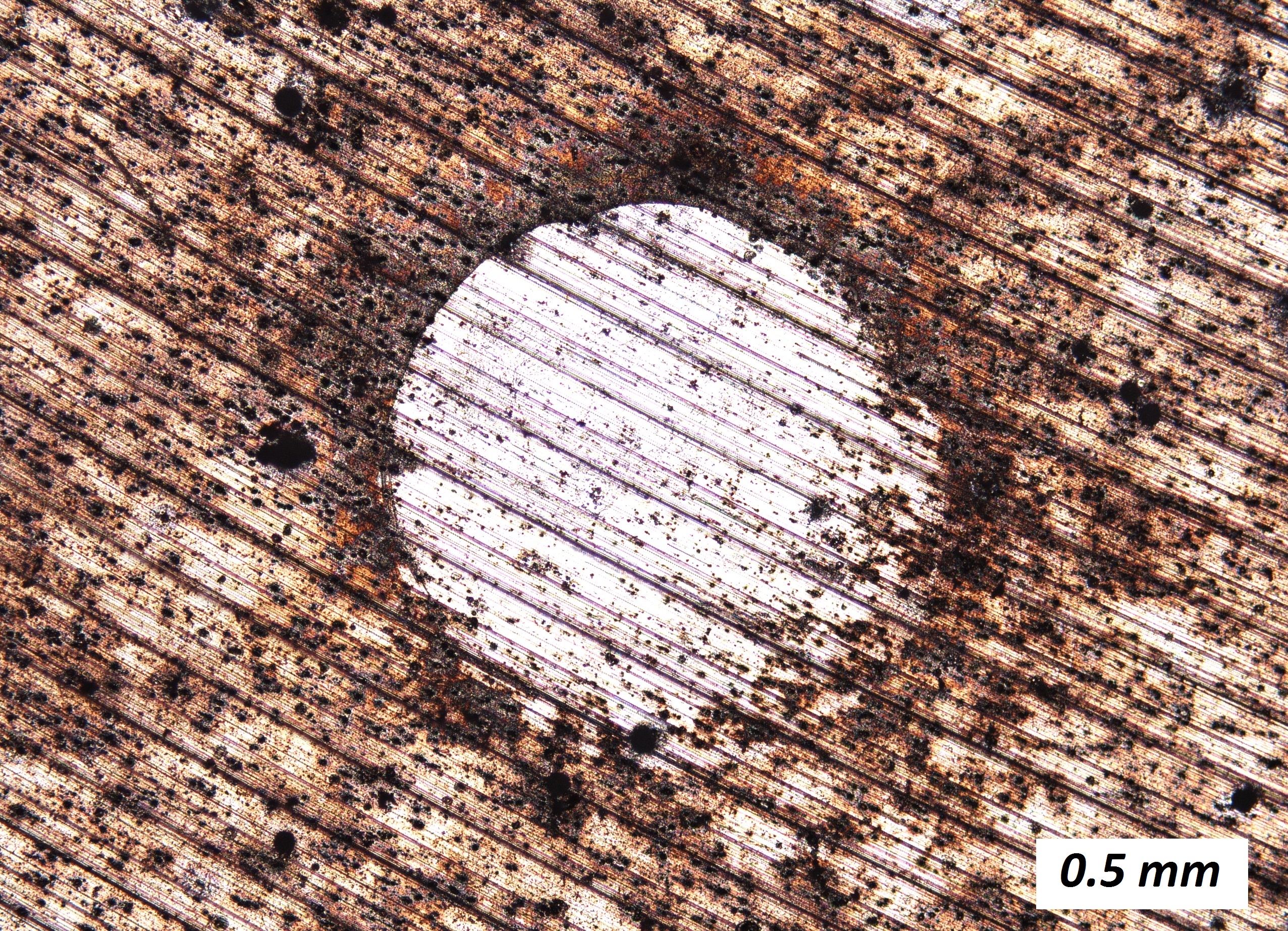

ZRS-4 USS Akron Duralumin Sample

USS ''Akron'' (ZRS-4) was a helium-filled rigid airship of the U.S. Navy, the lead ship of her class, which operated between September 1931 and April 1933. It was the world's first purpose-built flying aircraft carrier, carrying F9C Sparrowhawk fighter planes, which could be launched and recovered while it was in flight. With an overall length of , ''Akron'' and her sister ship were among the largest flying objects ever built. Although LZ 129 ''Hindenburg'' and LZ 130 ''Graf Zeppelin II'' were some longer and slightly more voluminous, the two German airships were filled with hydrogen, and so the two US Navy craft still hold the world record for the largest helium-filled airships. ''Akron'' was destroyed in a thunderstorm off the coast of New Jersey on the morning of 4 April 1933, killing 73 of the 76 crewmen and passengers. The accident involved the greatest loss of life in any airship crash. Technical description The airship's skeleton was built of the new lightweight ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Junkers J

Junkers Flugzeug- und Motorenwerke AG (JFM, earlier JCO or JKO in World War I, English: Junkers Aircraft and Motor Works) more commonly Junkers , was a major German aircraft and aircraft engine manufacturer. It was founded there in Dessau, Germany, in 1895 by Hugo Junkers, initially manufacturing boilers and radiators. During World War I and following the war, the company became famous for its pioneering all-metal aircraft. During World War II the company produced the German army's Luftwaffe planes, as well as piston and jet aircraft engines, albeit in the absence of its founder, who had been removed by the Nazis in 1934. History Early inter-war period In the immediate post-war era, Junkers used their J8 layout as the basis for the F-13, first flown on 25 June 1919 and certified airworthy in July of the same year. This four passenger monoplane was the world's first all-metal airliner. Of note, in addition to significant European sales, some twenty-five of these airplanes w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

2024 Aluminum

2024 aluminium alloy is an aluminium alloy, with copper as the primary alloying element. It is used in applications requiring high strength to weight ratio, as well as good fatigue resistance. It is weldable only through friction welding, and has average machinability. Due to poor corrosion resistance, it is often clad with aluminium or Al-1Zn for protection, although this may reduce the fatigue strength. In older systems of terminology, 2XXX series alloys were known as duralumin, and this alloy was named 24ST. 2024 is commonly extruded, and also available in alclad sheet and plate forms. It is not commonly forged (the related 2014 aluminium alloy is, though). Basic properties Aluminium alloy 2024 has a density of 2.78 g/cm3 (0.1 lb/in3), electrical conductivity of 30% IACS, Young's Modulus of 73 GPa (10.6 Msi) across all tempers, and begins to melt at . 2024 aluminium alloy's composition roughly includes 4.3–4.5% copper, 0.5–0.6% manganese, 1.3–1.5% magnesium and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium Alloy

An aluminium alloy (or aluminum alloy; see spelling differences) is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.I. J. Polmear, ''Light Alloys'', Arnold, 1995 Alloys c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

2024 Aluminium Alloy

2024 aluminium alloy is an aluminium alloy, with copper as the primary alloying element. It is used in applications requiring high strength to weight ratio, as well as good fatigue resistance. It is weldable only through friction welding, and has average machinability. Due to poor corrosion resistance, it is often clad with aluminium or Al-1Zn for protection, although this may reduce the fatigue strength. In older systems of terminology, 2XXX series alloys were known as duralumin, and this alloy was named 24ST. 2024 is commonly extruded, and also available in alclad sheet and plate forms. It is not commonly forged (the related 2014 aluminium alloy is, though). Basic properties Aluminium alloy 2024 has a density of 2.78 g/cm3 (0.1 lb/in3), electrical conductivity of 30% IACS, Young's Modulus of 73 GPa (10.6 Msi) across all tempers, and begins to melt at . 2024 aluminium alloy's composition roughly includes 4.3–4.5% copper, 0.5–0.6% manganese, 1.3–1.5% magnesium and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It has a great affinity towards oxygen, and forms a protective layer of oxide on the surface when exposed to air. Aluminium visually resembles silver, both in its color and in its great ability to reflect light. It is soft, non-magnetic and ductile. It has one stable isotope, 27Al; this isotope is very common, making aluminium the twelfth most common element in the Universe. The radioactivity of 26Al is used in radiodating. Chemically, aluminium is a post-transition metal in the boron group; as is common for the group, aluminium forms compounds primarily in the +3 oxidation state. The aluminium cation Al3+ is small and highly charged; as such, it is polarizing, and bonds aluminium forms tend towards covalency. The strong affinity tow ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

2014 Aluminum Alloy

2014 aluminium alloy (aluminum) is an aluminium-based alloy often used in the aerospace industry. It is easily machined in certain tempers, and among the strongest available aluminium alloys, as well as having high hardness. However, it is difficult to weld, as it is subject to cracking. 2014 is the second most popular of the 2000-series aluminium alloys, after 2024 aluminium alloy. It is commonly extruded and forged. The corrosion resistance of this alloy is particularly poor. To combat this, it is often clad with pure aluminium. If unclad 2014 aluminium is to be exposed to the elements, it should be painted as a corrosion protection measure. Prior to the adoption of The Aluminum Association alloy designations in 1954, 2014 was known by the industry conventional designation "14S". Chemical composition The alloy composition of 2014 is: *Aluminium: Remainder *Chromium: 0.1% max *Copper: 3.9% - 5% *Iron: 0.7% max *Magnesium: 0.2% - 0.8% *Manganese: 0.4 - 1.2% *Remainder: Each 0. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes. Mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

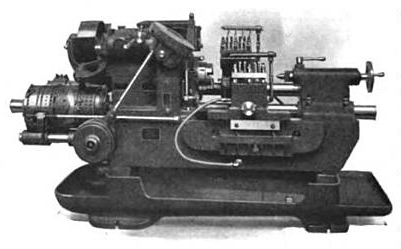

Screw Machine (automatic Lathe)

In metalworking and woodworking, an automatic lathe is a lathe with an automatically controlled cutting process. Automatic lathes were first developed in the 1870s and were mechanically controlled. From the advent of NC and CNC in the 1950s, the term automatic lathe has generally been used for only mechanically controlled lathes, although some manufacturers (e.g., DMG Mori and Tsugami) market Swiss-type CNC lathes as 'automatic'. CNC has not yet entirely displaced mechanically automated lathes, as although no longer in production, many mechanically automated lathes remain in service. General nomenclature The term "automatic lathe" is still often used in manufacturing in its earlier sense, referring to automated lathes of non-CNC types. The first automatic lathes were mechanically automated and controlled by cams or tracers and pantographs. Thus, before electronic automation via numerical control, the "automatic" in the term "automatic machine tool" always referred implicitly ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machinability

Machinability is the ease with which a metal can be cut (machined) permitting the removal of the material with a satisfactory finish at low cost.Degarmo, p. 542. Materials with good machinability (free machining materials) require little power to cut, can be cut quickly, easily obtain a good finish, and do not cause significant wear on the tooling. Factors that typically improve a material's performance often degrade its machinability, presenting a significant engineering challenge. Machinability can be difficult to predict due to the large number of variables involved in the machining process. Two sets of factors are the condition of work materials and the physical properties of work materials. The condition of the work material includes at least eight factors: microstructure, grain size, heat treatment, chemical composition, fabrication, hardness, yield strength, and tensile strength.Schneider, "Machinability." Physical properties are those of the individual material groups, such ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons.Degarmo, p. 389 Forging has been done by smiths for millennia; the traditional products were kitchenware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanisms and machines wherever a component requires high strength; such forgings usually require further processing (such as machining) to achieve a finished part. Today, forging is a major worldwide industry. History Forging is one of the oldest known me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |