|

Directional Drilling

Directional drilling (or slant drilling) is the practice of drilling non-vertical bores. It can be broken down into four main groups: oilfield directional drilling, utility installation directional drilling, directional boring (horizontal directional drilling - HDD), and surface in seam (SIS), which horizontally intersects a vertical bore target to extract coal bed methane. History Many prerequisites enabled this suite of technologies to become productive. Probably, the first requirement was the realization that oil wells, or water wells, do not necessarily need to be vertical. This realization was quite slow, and did not really grasp the attention of the oil industry until the late 1920s when there were several lawsuits alleging that wells drilled from a rig on one property had crossed the boundary and were penetrating a reservoir on an adjacent property. Initially, proxy evidence such as production changes in other wells was accepted, but such cases fueled the development of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotary Steerable System

A rotary steerable system (RSS) is a form of drilling technology used in directional drilling. It employs the use of specialized downhole equipment to replace conventional directional tools such as mud motors. They are generally programmed by the measurement while drilling (MWD) engineer or directional driller who transmits commands using surface equipment (typically using either pressure fluctuations in the mud column or variations in the drill string rotation) which the tool responds to, and gradually steers into the desired direction. In other words, a tool designed to drill directionally with continuous rotation from the surface, eliminating the need to "slide" a mud motor. The first known patent application is from Christopher G. Cross in 1873 for "Drills for Boring Artesian Wells", followed in 1884 by the brothers Morris and Clarence Baker for a "Machine for Operating Drills" The methods used to direct the well path fall into two broad categories, these being “push-the-bi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Enid, Oklahoma

Enid ( ) is the ninth-largest city in the U.S. state of Oklahoma. It is the county seat of Garfield County. As of the 2020 census, the population was 51,308. Enid was founded during the opening of the Cherokee Outlet in the Land Run of 1893, and is named after Enid, a character in Alfred, Lord Tennyson's '' Idylls of the King''. In 1991, the Oklahoma state legislature designated Enid the " purple martin capital of Oklahoma."Purple Martin State Capitals ", ''Nature Society News'', June 2006, p. 8. Enid holds the nickname of "Queen Wheat City" and "Wheat Capital" of Oklahoma and the United States for its immense grain storage capacity, and has the third-largest grain storage capacity in the world. History [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Relief Well

Relief wells are used both in the natural gas and petroleum industry and in flood control. Fossil fuels In the natural gas and petroleum industry, a relief well is drilled to intersect an oil or gas well that has experienced a blowout. Specialized liquid, such as heavy (dense) drilling mud followed by cement, can then be pumped down the relief well in order to stop the flow from the reservoir in the damaged well. The first use of a relief well was in Texas in the mid-1930s when one was drilled to pump water into an oil well that had cratered and caught on fire. Flood control In flood control, a different type of relief well is used adjacent to earthen levees to relieve the pressure on the lake or river side of the levee and thus to prevent the collapse of the levee. The greater flow of water in the water source, typically during a flood, creates a pressure gradient such that more water infiltrates the soil of the levee. Water may then flow through the soil towards the dry side ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Platform

An oil platform (or oil rig, offshore platform, oil production platform, and similar terms) is a large structure with facilities to extract and process petroleum and natural gas that lie in rock formations beneath the seabed. Many oil platforms will also have facilities to accommodate the workers, although it is also common to have a separate accommodation platform bridge linked to the production platform. Most commonly, oil platforms engage in activities on the continental shelf, though they can also be used in lakes, inshore waters, and inland seas. Depending on the circumstances, the platform may be fixed Platform, fixed to the ocean floor, consist of an artificial island, or floating oil production system, float. In some arrangements the main facility may have storage facilities for the processed oil. Remote subsea wells may also be connected to a platform by flow lines and by umbilical cable, umbilical connections. These sub-sea facilities may include of one or more subsea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wellhead

A wellhead is the component at the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment. The primary purpose of a wellhead is to provide the suspension point and pressure seals for the casing strings that run from the bottom of the hole sections to the surface pressure control equipment. While drilling the oil well, surface pressure control is provided by a blowout preventer (BOP). If the pressure is not contained during drilling operations by the column of drilling fluid, casings, wellhead, and BOP, a well blowout could occur. When the well has been drilled, it is completed to provide an interface with the reservoir rock and a tubular conduit for the well fluids. The surface pressure control is provided by a Christmas tree, which is installed on top of the wellhead, with isolation valves and choke equipment to control the flow of well fluids during production. Wellheads are typically welded on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electromagnetism

In physics, electromagnetism is an interaction that occurs between particles with electric charge. It is the second-strongest of the four fundamental interactions, after the strong force, and it is the dominant force in the interactions of atoms and molecules. Electromagnetism can be thought of as a combination of electricity and magnetism, two distinct but closely intertwined phenomena. In essence, electric forces occur between any two charged particles, causing an attraction between particles with opposite charges and repulsion between particles with the same charge, while magnetism is an interaction that occurs exclusively between ''moving'' charged particles. These two effects combine to create electromagnetic fields in the vicinity of charge particles, which can exert influence on other particles via the Lorentz force. At high energy, the weak force and electromagnetic force are unified as a single electroweak force. The electromagnetic force is responsible for many o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

IntelliServ

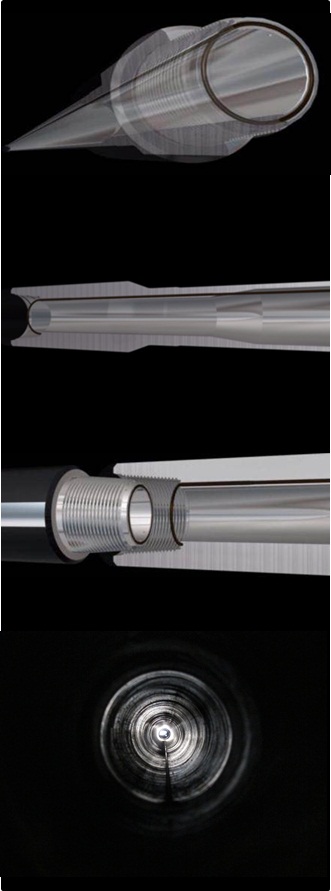

IntelliServ is a National Oilwell Varco brand that manufactures and sells a broadband networked drilling string system used to transmit downhole information to the surface in a drilling operation. Background The IntelliServ network is a broadband telemetry system that allows instant transmission of data between the surface and the measurement tools positioned in the drill string bottomhole assembly near the drill bit. The invention of IntelliServ technology began in 1997 with a project on hydraulic mud hammers sponsored by the company Novatek and the United States Department of Energy."Grant Prideco's IntelliServ poised to take the drilling industry from dial-up into the world of broadband." Hsieh, Linda. Drilling Contractor Magazine. March/A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mud Motor

A mud motor (or drilling motor) is a progressive cavity positive displacement pump (PCPD) placed in the drill string to provide additional power to the bit while drilling. The PCPD pump uses drilling fluid (commonly referred to as drilling mud, or just mud) to create eccentric motion in the power section of the motor which is transferred as concentric power to the drill bit. The mud motor uses different rotor and stator configurations to provide optimum performance for the desired drilling operation, typically increasing the number of lobes and length of power assembly for greater horsepower. In certain applications, compressed air, or other gas, can be used for mud motor input power. Normal rotation of the bit while using a mud motor can be from 60 rpm to over 100 rpm. Basic principle Based on the principle developed by Rene Moineau, the theory states that a helical rotor with one or more lobes will rotate eccentrically when the stator contains more lobes than the rotor. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.gif)