|

Circulating Fluidised Bed Combustion

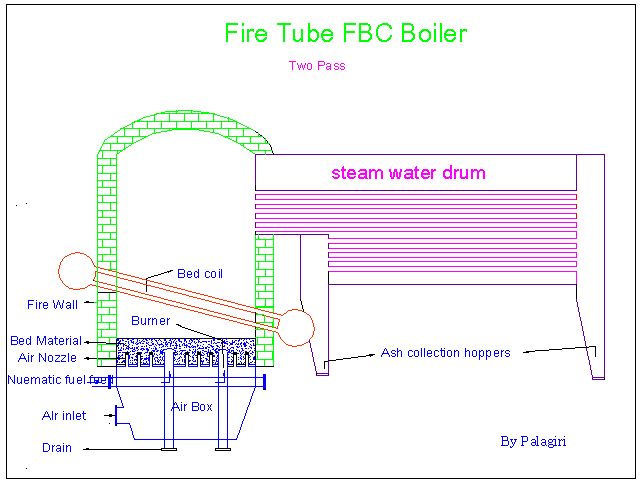

Fluidized bed combustion (FBC) is a combustion technology used to burn solid fuels. In its most basic form, fuel particles are suspended in a hot, bubbling fluidity bed of ash and other particulate materials ( sand, limestone etc.) through which jets of air are blown to provide the oxygen required for combustion or gasification. The resultant fast and intimate mixing of gas and solids promotes rapid heat transfer and chemical reactions within the bed. FBC plants are capable of burning a variety of low-grade solid fuels, including most types of coal, coal waste and woody biomass, at high efficiency and without the necessity for expensive fuel preparation (e.g., pulverising). In addition, for any given thermal duty, FBCs are smaller than the equivalent conventional furnace, so may offer significant advantages over the latter in terms of cost and flexibility. FBC reduces the amount of sulfur emitted in the form of SO''x'' emissions. Limestone is used to precipitate out sulfat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sorbent

A sorbent is a material used to absorb or adsorb liquids or gases. Examples include: *A material similar to molecular sieve material, which acts by adsorption (attracting molecules to its surface). It has a large internal surface area and good thermal conductivity. It is typically supplied in pellets of 1 mm to 2 mm diameter and roughly 5 mm length or as grains of the order 1 mm. Occasionally as beads up to 5 mm diameter. They are typically made from aluminium oxide with a porous structure. *Materials used to absorb other materials due to their high affinity for doing so. Examples include: **In composting, dry (brown, high-carbon) materials absorb many odoriferous chemicals, and these chemicals help to decompose these sorbents. **A sponge absorbs many times its own weight in water. **A polypropylene fiber mat may be used to absorb oil. **A cellulose fiber product may be used to absorb oil. **The granular gel material in a baby diaper will absorb several t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pulverised Fuel Firing

A pulverized coal-fired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in cosmetic makeup) that is blown into the firebox. The basic idea of a firing system using pulverised fuel is to use the whole volume of the furnace for the combustion of solid fuels. Coal is ground to the size of a fine grain, mixed with air and burned in the flue gas flow. Biomass and other materials can also be added to the mixture. Coal contains mineral matter which is converted to ash during combustion. The ash is removed as bottom ash and fly ash. The bottom ash is removed at the furnace bottom. This type of boiler dominates coal-fired power stations, providing steam to drive large turbines. History Prior to the developments leading to the use of pulverized coal, most boilers utilized grate firing where the fuel was mechanically distributed onto a moving grate at the bottom of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

JEA Northside Generating Station (Jacksonville)

JEA Northside Generating Station in Jacksonville, Florida is a major power plant, one of the three power plants owned and operated by JEA, Jacksonville's municipal utilities service. It produces electricity by burning coal and petroleum coke at Units 1 and 2, formerly the largest circulating fluidized-bed combustors, (CFBs), in the world. These combustors, completed in 2002 and rated at 297.5 megawatts each, produce enough electricity to light more than 250,000 households. In addition, Unit ST3 produces 505 megawatts of electricity by burning residual fuel oil and/or natural gas. Location The Northside Generating Station is located north-east of the interchange of Interstate 295 and State Road 105 in the city of Jacksonville, Florida. It is from the Atlantic Ocean coastline, on the north bank of a back channel of the St. Johns River, which is being used as a waterway for fuel delivery as well as a source of cooling water. The Northside Generating Station also borders Timucua ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grate Firing

Grate firing is a type of industrial combustion system used for solid fuels. It now is used mainly for burning waste and biomass, but also for smaller coal Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen. Coal is formed when dea ... furnaces. * Capacities 0.3 to 175 MWth in industry and CHP * Fuel fired per grate area 1-2 MW/m2, maximum grate area 100 m2 * Grates are typical only suitable for coarse particles, for fine particles a spreader is required, increases max. capacity * Primary air through the grate (also used for cooling) and secondary air Types ;Travelling grate :A moving grate which is covered with a fuel layer, 10-30 cm. Power control by means of varying the grate velocity ;Reciprocating grate :For ash-rich, low calorific fuels like municipal waste, arrangement of stationary and moving grates ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

FutureGen

FutureGen was a project to demonstrate capture and sequestration of waste carbon dioxide from a coal-fired electrical generating station. The project (renamed FutureGen 2.0) was retrofitting a shuttered coal-fired power plant in Meredosia, Illinois, with oxy-combustion generators. The waste CO2 would be piped approximately to be sequestered in underground saline formations. FutureGen was a partnership between the United States government and an alliance of primarily coal-related corporations. Costs were estimated at US$1.65 billion, with $1.0 billion provided by the Federal Government. First announced by President George W. Bush in 2003, construction started in 2014 after restructuring, canceling, relocating, and restarting. Citing an inability to commit and spend the funds by deadlines in 2015, the Department of Energy withdrew funds and suspended FutureGen 2.0 in February, 2015. The government also cited the Alliance's inability to raise the requisite amount of priv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluidized Bed Reactor

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid (gas or liquid) is passed through a solid granular material (usually a catalyst) at high enough speeds to suspend the solid and cause it to behave as though it were a fluid. This process, known as fluidization, imparts many important advantages to an FBR. As a result, FBRs are used for many industrial applications. Basic principles The solid substrate material (the catalytic material upon which chemical species react) in the fluidized bed reactor is typically supported by a porous plate, known as a distributor.Howard, J. R. (1989). ''Fluidized Bed Technology: Principles and Applications.'' New York, NY: Adam Higler. The fluid is then forced through the distributor up through the solid material. At lower fluid velocities, the solids remain in place as the fluid passes through the voids in the material. This is know ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Circulating Fluidized Bed

The circulating fluidized bed (CFB) is a type of Fluidized bed combustion that utilizes a recirculating loop for even greater efficiency of combustion. while achieving lower emission of pollutants. Reports suggest that up to 95% of pollutants Circulating Fluidized Bed Technology'', The Circulating Fluidized Bed Technology, 2010, Innovation and Information for sustainable living can be absorbed before being emitted into the atmosphere. The technology is limited in scale however, due to its extensive use of limestone, and the fact that it produces waste byproducts. Introduction Fluidization is the phenomenon by which solid particles are transported into a fluid-like state through suspension in a gas or liquid. The resultant mixing of gas and solids promotes rapid heat transfer and chemical reactions within the bed. Power plants that use this technology are capable of burning low grade fuels at high efficiency and without the need for expensive fuel preparation. They are also smal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

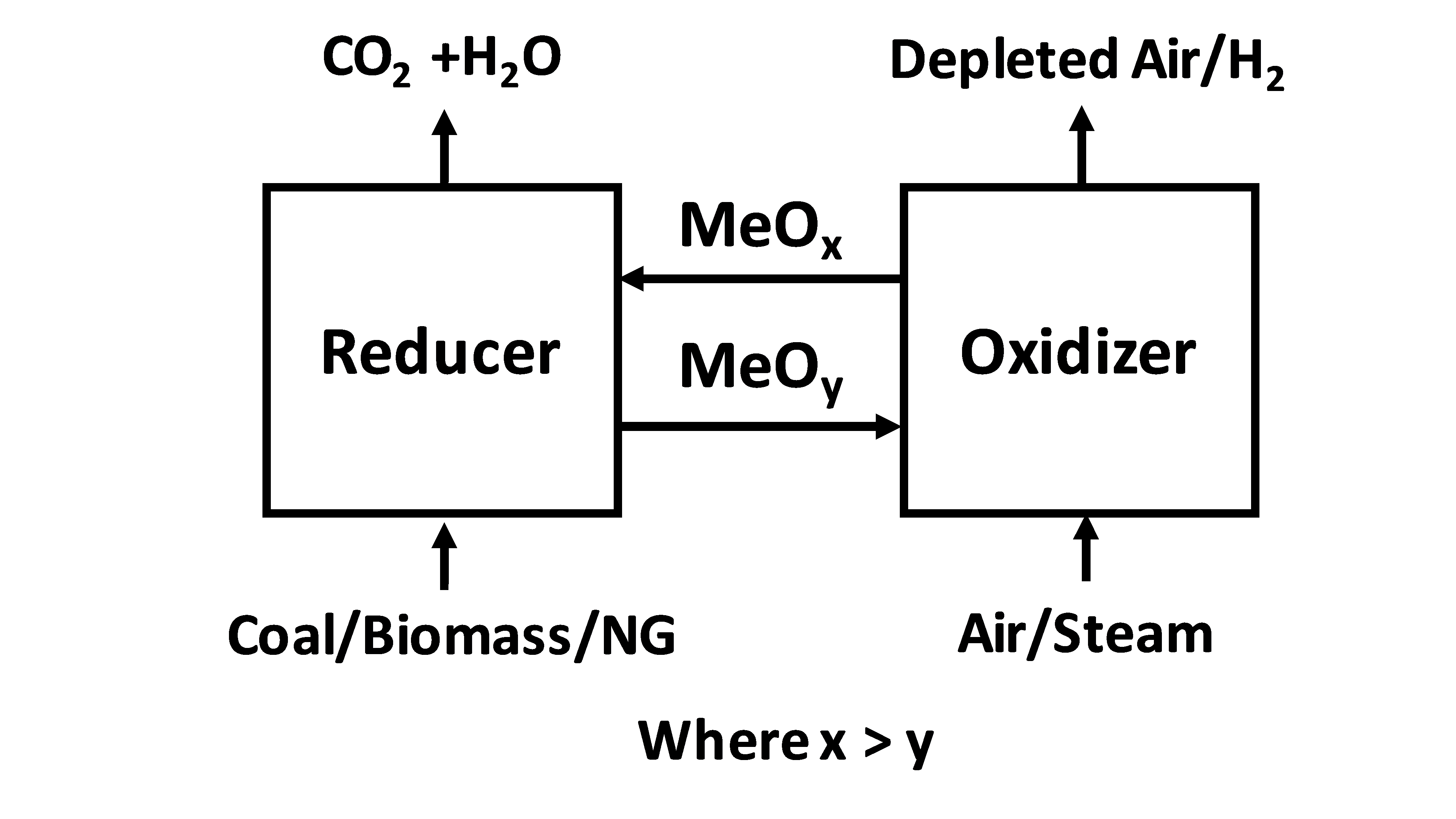

Chemical Looping Combustion

Chemical looping combustion (CLC) is a technological process typically employing a dual fluidized bed system. CLC operated with an interconnected moving bed with a fluidized bed system, has also been employed as a technology process. In CLC, a metal oxide is employed as a bed material providing the oxygen for combustion in the fuel reactor. The reduced metal is then transferred to the second bed ( air reactor) and re-oxidized before being reintroduced back to the fuel reactor completing the loop. Fig 1 shows a simplified diagram of the CLC process. Fig 2 shows an example of a dual fluidized bed circulating reactor system and a moving bed-fluidized bed circulating reactor system. Isolation of the fuel from air simplifies the number of chemical reactions in combustion. Employing oxygen without nitrogen and the trace gases found in air eliminates the primary source for the formation of nitrogen oxide (), produces a flue gas composed primarily of carbon dioxide and water vapor; other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Syngas

Syngas, or synthesis gas, is a mixture of hydrogen and carbon monoxide, in various ratios. The gas often contains some carbon dioxide and methane. It is principly used for producing ammonia or methanol. Syngas is combustible and can be used as a fuel. Historically, it has been used as a replacement for gasoline, when gasoline supply has been limited; for example, wood gas was used to power cars in Europe during WWII (in Germany alone half a million cars were built or rebuilt to run on wood gas). Production Syngas is produced by steam reforming or partial oxidation of natural gas or liquid hydrocarbons, or coal gasification. Steam reforming of methane is an endothermic reaction requiring 206 kJ/mol of methane: : In principle, but rarely in practice, biomass and related hydrocarbon feedstocks could be used to generate biogas and biochar in waste-to-energy gasification facilities. The gas generated (mostly methane and carbon dioxide) is sometimes described as ''syngas'' but its co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Natural Gas

Natural gas (also called fossil gas or simply gas) is a naturally occurring mixture of gaseous hydrocarbons consisting primarily of methane in addition to various smaller amounts of other higher alkanes. Low levels of trace gases like carbon dioxide, nitrogen, hydrogen sulfide, and helium are also usually present. Natural gas is colorless and odorless, so odorizers such as mercaptan (which smells like sulfur or rotten eggs) are commonly added to natural gas supplies for safety so that leaks can be readily detected. Natural gas is a fossil fuel and non-renewable resource that is formed when layers of organic matter (primarily marine microorganisms) decompose under anaerobic conditions and are subjected to intense heat and pressure underground over millions of years. The energy that the decayed organisms originally obtained from the sun via photosynthesis is stored as chemical energy within the molecules of methane and other hydrocarbons. Natural gas can be burned fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Combined Cycle

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs. The principle is that after completing its cycle in the first engine, the working fluid (the exhaust) is still hot enough that a second subsequent heat engine can extract energy from the heat in the exhaust. Usually the heat passes through a heat exchanger so that the two engines can use different working fluids. By generating power from multiple streams of work, the overall efficiency can be increased by 50–60%. That is, from an overall efficiency of the system of say 34% for a simple cycle, to as much as 64% ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |