|

Chillers

A chiller is a machine that removes heat from a liquid coolant via a vapor-compression, adsorption refrigeration, or absorption refrigeration cycles. This liquid can then be circulated through a heat exchanger to cool equipment, or another process stream (such as air or process water). As a necessary by-product, refrigeration creates waste heat that must be exhausted to ambience, or for greater efficiency, recovered for heating purposes. Vapor compression chillers may use any of a number of different types of compressors. Most common today are the hermetic scroll, semi-hermetic screw, or centrifugal compressors. The condensing side of the chiller can be either air or water cooled. Even when liquid cooled, the chiller is often cooled by an induced or forced draft cooling tower. Absorption and adsorption chillers require a heat source to function. Chilled water is used to cool and dehumidify air in mid- to large-size commercial, industrial, and institutional facilities. Water co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chiller

A chiller is a machine that removes heat from a liquid coolant via a vapor-compression refrigeration, vapor-compression, adsorption refrigeration, or absorption refrigerator, absorption refrigeration cycles. This liquid can then be circulated through a heat exchanger to cool equipment, or another process stream (such as air or process water). As a necessary by-product, refrigeration creates waste heat that must be exhausted to ambience, or for greater efficiency, recovered for heating purposes. Vapor compression chillers may use any of a number of different types of compressors. Most common today are the hermetic scroll, semi-hermetic screw, or centrifugal compressors. The condensing side of the chiller can be either air or water cooled. Even when liquid cooled, the chiller is often cooled by an induced or forced draft cooling tower. Absorption and adsorption chillers require a heat source to function. Chilled water is used to Air conditioning, cool and dehumidify air in mid- to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbine Inlet Air Cooling

Turbine inlet air cooling is a group of technologies and techniques consisting of cooling down the intake air of the gas turbine. The direct consequence of cooling the turbine inlet air is power output augmentation. It may also improve the energy efficiency of the system. This technology is widely used in hot climates with high ambient temperatures that usually coincides with on-peak demand period. Principles Gas turbines take in filtered, fresh ambient air and compress it in the compressor stage. The compressed air is mixed with fuel in the combustion chamber and ignited. This produces a high-temperature and high-pressure flow of exhaust gases that enter in a turbine and produce the shaft work output that is generally used to turn an electric generator as well as powering the compressor stage. As the gas turbine is a constant volume machine, the air volume introduced in the combustion chamber after the compression stage is fixed for a given shaft speed (rpm). Thus the air mass ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vapor-compression Refrigeration

Vapour-compression refrigeration or vapor-compression refrigeration system (VCRS), in which the refrigerant undergoes phase changes, is one of the many refrigeration cycles and is the most widely used method for air conditioning of buildings and automobiles. It is also used in domestic and commercial refrigerators, large-scale warehouses for chilled or frozen storage of foods and meats, refrigerated trucks and railroad cars, and a host of other commercial and industrial services. Oil refineries, petrochemical and chemical processing plants, and natural gas processing plants are among the many types of industrial plants that often utilize large vapor-compression refrigeration systems. Cascade refrigeration systems may also be implemented using two compressors. Refrigeration may be defined as lowering the temperature of an enclosed space by removing heat from that space and transferring it elsewhere. A device that performs this function may also be called an air conditioner, refrige ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air Conditioning

Air conditioning, often abbreviated as A/C or AC, is the process of removing heat from an enclosed space to achieve a more comfortable interior environment (sometimes referred to as 'comfort cooling') and in some cases also strictly controlling the humidity of internal air. Air conditioning can be achieved using a mechanical 'air conditioner' or alternatively a variety of other methods, including passive cooling or ventilative cooling. Air conditioning is a member of a family of systems and techniques that provide heating, ventilation, and air conditioning (HVAC). Heat pumps are similar in many ways to air conditioners, but use a reversing valve to allow them to both heat and also cool an enclosed space. Air conditioners, which typically use vapor-compression refrigeration, range in size from small units used within vehicles or single rooms to massive units that can cool large buildings. Air source heat pumps, which can be used for heating as well as cooling, are becoming incre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

District Cooling

District cooling is the cooling equivalent of district heating. Working on broadly similar principles to district heating, district cooling delivers chilled water to buildings like offices and factories needing cooling. In winter, the source for the cooling can often be seawater, so it is a cheaper resource than using electricity to run compressors for cooling. Alternatively, District Cooling can be provided by a Heat Sharing Network which enables each building on the circuit to use a heat pump to reject heat to an ambient ground temperature circuit. There are also ''5th generation district heating and cooling systems'' (so called cold district heating networks) that are able to provide both heating and cooling simultaneously. In these systems the waste heat from chillers can be recycled and used for space heating or hot water production. Applications Canada In August 2004, Enwave Energy Corporation, a district energy company based in Toronto, Ontario, Canada, started operating a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air Conditioning

Air conditioning, often abbreviated as A/C or AC, is the process of removing heat from an enclosed space to achieve a more comfortable interior environment (sometimes referred to as 'comfort cooling') and in some cases also strictly controlling the humidity of internal air. Air conditioning can be achieved using a mechanical 'air conditioner' or alternatively a variety of other methods, including passive cooling or ventilative cooling. Air conditioning is a member of a family of systems and techniques that provide heating, ventilation, and air conditioning (HVAC). Heat pumps are similar in many ways to air conditioners, but use a reversing valve to allow them to both heat and also cool an enclosed space. Air conditioners, which typically use vapor-compression refrigeration, range in size from small units used within vehicles or single rooms to massive units that can cool large buildings. Air source heat pumps, which can be used for heating as well as cooling, are becoming incre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the direction of flow: * a rotating gas compressor * a combustor * a compressor-driving turbine. Additional components have to be added to the gas generator to suit its application. Common to all is an air inlet but with different configurations to suit the requirements of marine use, land use or flight at speeds varying from stationary to supersonic. A propelling nozzle is added to produce thrust for flight. An extra turbine is added to drive a propeller (turboprop) or ducted fan (turbofan) to reduce fuel consumption (by increasing propulsive efficiency) at subsonic flight speeds. An extra turbine is also required to drive a helicopter rotor or land-vehicle transmission (turboshaft), marine propeller or electrical generator (power turbine). Greater ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam Turbine

A steam turbine is a machine that extracts thermal energy from pressurized steam and uses it to do mechanical work on a rotating output shaft. Its modern manifestation was invented by Charles Parsons in 1884. Fabrication of a modern steam turbine involves advanced metalwork to form high-grade steel alloys into precision parts using technologies that first became available in the 20th century; continued advances in durability and efficiency of steam turbines remains central to the energy economics of the 21st century. The steam turbine is a form of heat engine that derives much of its improvement in thermodynamic efficiency from the use of multiple stages in the expansion of the steam, which results in a closer approach to the ideal reversible expansion process. Because the turbine generates rotary motion, it can be coupled to a generator to harness its motion into electricity. Such turbogenerators are the core of thermal power stations which can be fueled by fossil-fuels, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electric Motors

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft. An electric generator is mechanically identical to an electric motor, but operates with a reversed flow of power, converting mechanical energy into electrical energy. Electric motors can be powered by direct current (DC) sources, such as from batteries, or rectifiers, or by alternating current (AC) sources, such as a power grid, inverters or electrical generators. Electric motors may be classified by considerations such as power source type, construction, application and type of motion output. They can be powered by AC or DC, be brushed or brushless, single-phase, two-phase, or three-phase, axial or radial flux, and may be air-cooled or liquid-cooled. Standardized motors provide c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Centrifugal Compressor

Centrifugal compressors, sometimes called impeller compressors or radial compressors, are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. They achieve pressure rise by adding energy to the continuous flow of fluid through the rotor/impeller. The following equation shows this specific energy input. A substantial portion of this energy is kinetic which is converted to increased potential energy/static pressure by slowing the flow through a diffuser. The static pressure rise in the impeller may roughly equal the rise in the diffuser. Equation-0.1 : H = \left( \left( R \right)_2 - \left( R \right)_1 \right) :where the control volume nomenclature (illustrated in Figure-0.4) is: ::* subscript, is the impeller inlet location, station1 ::* subscript, is the impeller discharge/exit location, station2 ::* is the energy input per unit mass, units=(LP/m) ::* is the impeller's rotation speed, units=(radians/t) ::* is the radius of specified location, units=(L) ::* is ve ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotary Screw Compressor

A rotary-screw compressor is a type of gas compressor, such as an air compressor, that uses a rotary-type positive-displacement mechanism. These compressors are common in industrial applications and replace more traditional piston compressors where larger volumes of compressed gas are needed, e.g. for large refrigeration cycles such as chillers, or for compressed air systems to operate air-driven tools such as jackhammers and impact wrenches. For smaller rotor sizes the inherent leakage in the rotors becomes much more significant, leading to this type of mechanism being less suitable for smaller compressors than piston compressors. The screw compressor is identical to the screw pump except that the pockets of trapped material get progressively smaller along the screw, thus compressing the material held within the pockets. Thus the screw of a screw compressor is asymmetrical along its length, while a screw pump is symmetrical all the way. The gas compression process of a rotary ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

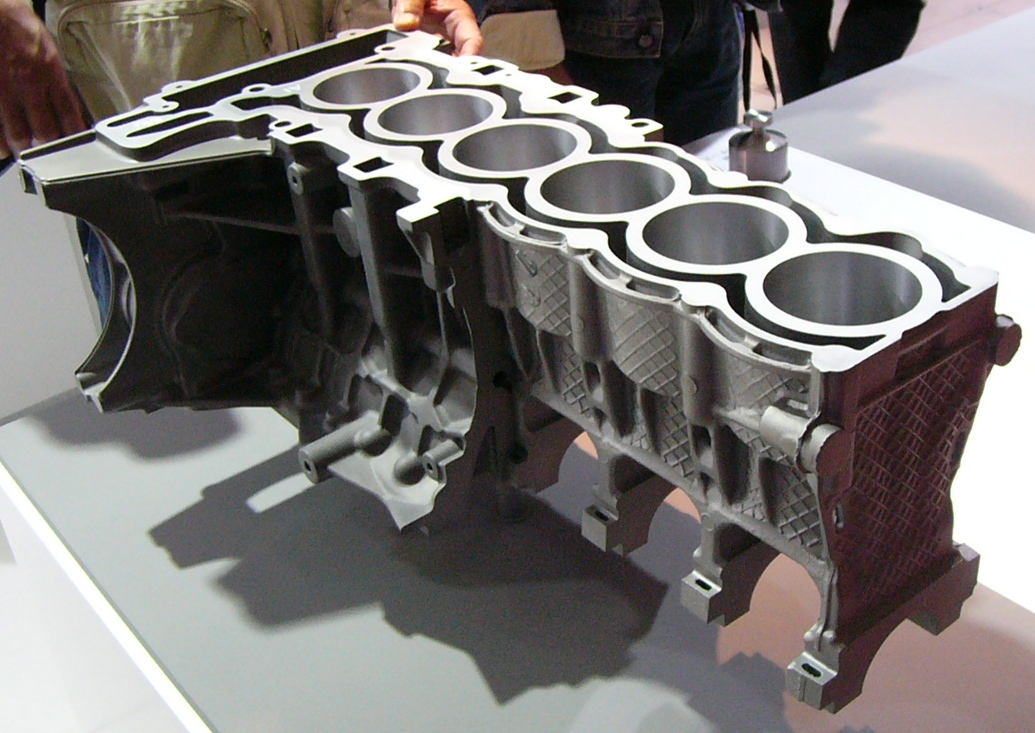

Die-casting

Die casting is a casting (metalworking), metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel die (manufacturing), dies which have been machined into shape and work similarly to an injection molding, injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used. The casting equipment and the metal dies represent large capital costs and this tends to limit the process to high-volume production. Manufacture of parts using die casting is relatively simple, involving only four main steps, which keeps the incremental cost per item low. It is especially suited for a large quantity of small- to medium-sized castings, which is why die casting produces more castings than any other casting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |