|

Cartesian Robot

A Cartesian coordinate robot (also called linear robot) is an industrial robot whose three principal axes of control are linear (i.e. they move in a straight line rather than rotate) and are at right angles to each other. The three sliding joints correspond to moving the wrist up-down, in-out, back-forth. Among other advantages, this mechanical arrangement simplifies the robot control arm solution. It has high reliability and precision when operating in three-dimensional space. As a robot coordinate system, it is also effective for horizontal travel and for stacking bins. Configurations Robots have mechanisms consisting of rigid links connected together by joints with either linear (prismatic ''P'') or rotary (revolute ''R'') motion, or combinations of the two. Active prismatic ''P'' and active revolute ''R'' joints are driven by motors under programmable control to manipulate objects to perform complex automated tasks. The linear motion of active prismatic ''P'' joints ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

3D Printing

3D printing or additive manufacturing is the Manufacturing, construction of a three-dimensional object from a computer-aided design, CAD model or a digital 3D modeling, 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under Computer Numerical Control, computer control, with material being added together (such as plastics, liquids or powder grains being fused), typically layer by layer. In the 1980s, 3D printing techniques were considered suitable only for the production of functional or aesthetic prototypes, and a more appropriate term for it at the time was rapid prototyping. , the precision, repeatability, and material range of 3D printing have increased to the point that some 3D printing processes are considered viable as an industrial-production technology, whereby the term ''additive manufacturing'' can be used synonymously with ''3D printing''. One of the key advantages of 3D printing is the ability to produce very ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laboratory Automation

Laboratory automation is a multi-disciplinary strategy to research, develop, optimize and capitalize on technologies in the laboratory that enable new and improved processes. Laboratory automation professionals are academic, commercial and government researchers, scientists and engineers who conduct research and develop new technologies to increase productivity, elevate experimental data quality, reduce lab process cycle times, or enable experimentation that otherwise would be impossible. The most widely known application of laboratory automation technology is laboratory robotics. More generally, the field of laboratory automation comprises many different automated laboratory instruments, devices (the most common being autosamplers), software algorithms, and methodologies used to enable, expedite and increase the efficiency and effectiveness of scientific research in laboratories. The application of technology in today's laboratories is required to achieve timely progress and r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cantilever

A cantilever is a rigid structural element that extends horizontally and is supported at only one end. Typically it extends from a flat vertical surface such as a wall, to which it must be firmly attached. Like other structural elements, a cantilever can be formed as a beam, plate, truss, or slab. When subjected to a structural load at its far, unsupported end, the cantilever carries the load to the support where it applies a shear stress and a bending moment. Cantilever construction allows overhanging structures without additional support. In bridges, towers, and buildings Cantilevers are widely found in construction, notably in cantilever bridges and balconies (see corbel). In cantilever bridges, the cantilevers are usually built as pairs, with each cantilever used to support one end of a central section. The Forth Bridge in Scotland is an example of a cantilever truss bridge. A cantilever in a traditionally timber framed building is called a jetty or forebay. In the southe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling (machining)

Milling is the process of machining using rotary Milling cutter, cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

X-Y Table

{{Unreferenced, date=May 2009 X-Y tables, also known as cross working tables or coordinate tables, help provide horizontal motion for automated machinery such as assembly robots in manufacturing facilities. Robotic arms and other automated machinery have only a limited range of motion while their bases remain stationary; X-Y tables allow these basis to move horizontally along X and Y axis. Also known as XY stages, XY tables are motorized linear slides with linear motion based in bearings which are driven by a drive mechanism, typically a linear motor. XY tables are built and configured to provide high-performance positioning along multiple axis. Applications Serving industries including general machinery, pharmaceutical, manufacturing and semiconductor, XY tables offer precision-controlled automated movement. XY tables are broadly used in mechanical processes and applications including material handling, industrial automation equipment, machinery building and automated measurement. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

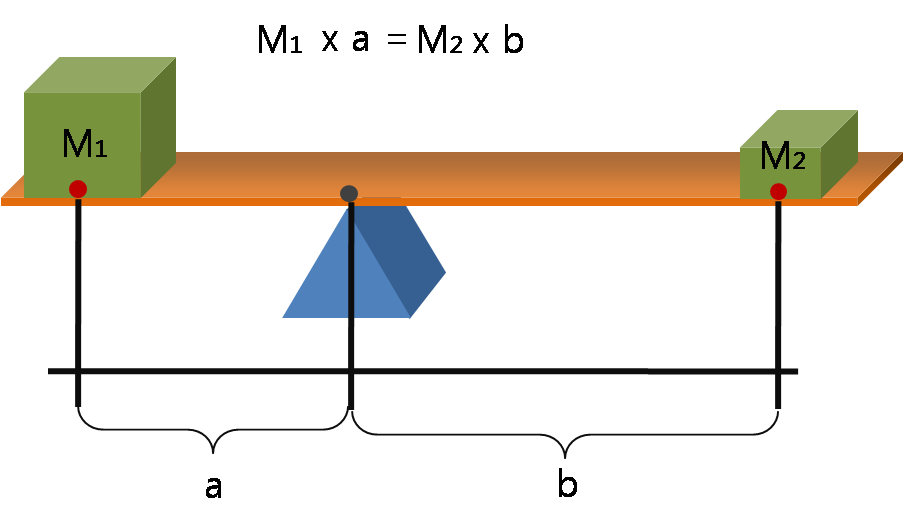

Moment (physics)

In physics, a moment is a mathematical expression involving the product of a distance and physical quantity. Moments are usually defined with respect to a fixed reference point and refer to physical quantities located some distance from the reference point. In this way, the moment accounts for the quantity's location or arrangement. For example, the moment of force, often called torque, is the product of a force on an object and the distance from the reference point to the object. In principle, any physical quantity can be multiplied by a distance to produce a moment. Commonly used quantities include forces, masses, and electric charge distributions. Elaboration In its most basic form, a moment is the product of the distance to a point, raised to a power, and a physical quantity (such as force or electrical charge) at that point: : \mu_n = r^n\,Q, where Q is the physical quantity such as a force applied at a point, or a point charge, or a point mass, etc. If the quantity ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Linear-motion Bearing

A linear-motion bearing or linear slide is a bearing designed to provide free motion in one direction. There are many different types of linear motion bearings. Motorized linear slides such as machine slides, X-Y tables, roller tables and some dovetail slides are bearings moved by drive mechanisms. Not all linear slides are motorized, and non-motorized dovetail slides, ball bearing slides and roller slides provide low-friction linear movement for equipment powered by inertia or by hand. All linear slides provide linear motion based on bearings, whether they are ball bearings, dovetail bearings, linear roller bearings, magnetic or fluid bearings. X-Y tables, linear stages, machine slides and other advanced slides use linear motion bearings to provide movement along both X and Y multiple axis. Rolling-element bearing A rolling-element bearing is generally composed of a sleeve-like outer ring and several rows of balls retained by cages. The cages were originally machined from soli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Actuator

An actuator is a component of a machine that is responsible for moving and controlling a mechanism or system, for example by opening a valve. In simple terms, it is a "mover". An actuator requires a control device (controlled by control signal) and a source of energy. The control signal is relatively low energy and may be electric voltage or current, pneumatic, or hydraulic fluid pressure, or even human power. Its main energy source may be an electric current, hydraulic pressure, or pneumatic pressure. The Control device is usually a valve. When it receives a control signal, an actuator responds by converting the source's energy into mechanical motion. In the ''electric'', ''hydraulic'', and ''pneumatic'' sense, it is a form of automation or automatic control. History The history of the pneumatic actuation system and the hydraulic actuation system dates to around the time of World War II (1938). It was first created by Xhiter Anckeleman who used his knowledge of engines and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

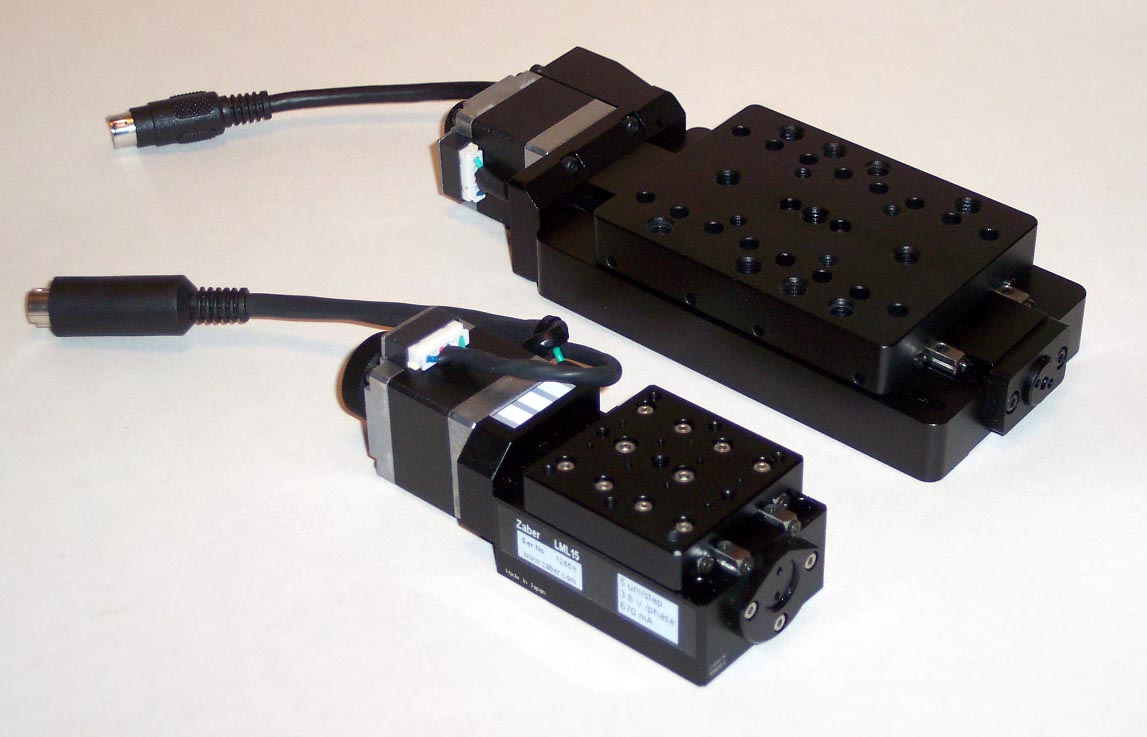

Linear Stage

A linear stage or translation stage is a component of a precise motion system used to restrict an object to a single axis of motion. The term linear slide is often used interchangeably with "linear stage", though technically "linear slide" refers to a linear motion bearing, which is only a component of a linear stage. All linear stages consist of a platform and a base, joined by some form of guide or linear bearing in such a way that the platform is restricted to linear motion with respect to the base. In common usage, the term linear stage may or may not also include the mechanism by which the position of the platform is controlled relative to the base. Principle of operation In three-dimensional space, an object may either rotate about, or translate along any of three axes. Thus the object is said to have six degrees of freedom (3 rotational and 3 translational). A linear stage exhibits only one degree of freedom (translation along one axis). In other words, linear stages opera ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Degrees Of Freedom (mechanics)

In physics, the degrees of freedom (DOF) of a mechanical system is the number of independent parameters that define its configuration or state. It is important in the analysis of systems of bodies in mechanical engineering, structural engineering, aerospace engineering, robotics, and other fields. The position of a single railcar (engine) moving along a track has one degree of freedom because the position of the car is defined by the distance along the track. A train of rigid cars connected by hinges to an engine still has only one degree of freedom because the positions of the cars behind the engine are constrained by the shape of the track. An automobile with highly stiff suspension can be considered to be a rigid body traveling on a plane (a flat, two-dimensional space). This body has three independent degrees of freedom consisting of two components of translation and one angle of rotation. Skidding or drifting is a good example of an automobile's three independent degrees ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

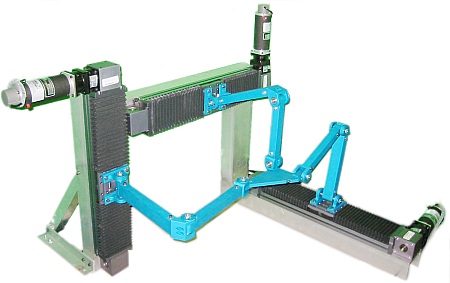

Cartesian Parallel Manipulators

In robotics, Cartesian parallel manipulators are manipulators that move a platform using parallel-connected kinematic linkages (`limbs') lined up with a Cartesian coordinate system. Multiple limbs connect the moving platform to a base. Each limb is driven by a linear actuator and the linear actuators are mutually perpendicular. The term `parallel' here refers to the way that the kinematic linkages are put together, it does not connote geometrically parallel; i.e., equidistant lines. Context Generally, manipulators (also called `robots' or ` mechanisms') are mechanical devices that position and orientate objects. The position of an object in three-dimensional (3D) space can be specified by three numbers ''X, Y, Z'' known as 'coordinates.' In a Cartesian coordinate system (named after René Descartes who introduced analytic geometry, the mathematical basis for controlling manipulators) the coordinates specify distances from three mutually perpendicular reference planes. The o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |