|

Curing (chemistry)

Curing is a chemical process employed in polymer chemistry and process engineering that produces the toughening or hardening of a polymer material by cross-linking of polymer chains. Even if it is strongly associated with the production of thermosetting polymers, the term "curing" can be used for all the processes where a solid product is obtained from a liquid solution, such as with PVC plastisols. Curing process During the curing process, single monomers and oligomers, mixed with or without a curing agent, react to form a tridimensional polymeric network. In the very first part of the reaction branches of molecules with various architectures are formed, and their molecular weight increases in time with the extent of the reaction until the network size is equal to the size of the system. The system has lost its solubility and its viscosity tends to infinite. The remaining molecules start to coexist with the macroscopic network until they react with the network creating other c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer Chemistry

Polymer chemistry is a sub-discipline of chemistry that focuses on the structures of chemicals, chemical synthesis, and chemical and physical properties of polymers and macromolecules. The principles and methods used within polymer chemistry are also applicable through a wide range of other chemistry sub-disciplines like organic chemistry, analytical chemistry, and physical chemistry. Many materials have polymeric structures, from fully inorganic metals and ceramics to DNA and other biological molecules. However, polymer chemistry is typically related to synthetic and organic compositions. Synthetic polymers are ubiquitous in commercial materials and products in everyday use, such as plastics, and rubbers, and are major components of composite materials. Polymer chemistry can also be included in the broader fields of polymer science or even nanotechnology, both of which can be described as encompassing polymer physics and polymer engineering.Hans-Heinrich Moretto, Manfred Sch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

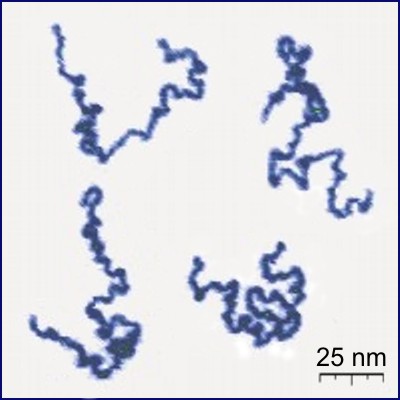

Gelation

In polymer chemistry, gelation (gel transition) is the formation of a gel from a system with polymers. Branched polymers can form links between the chains, which lead to progressively larger polymers. As the linking continues, larger branched polymers are obtained and at a certain extent of the reaction links between the polymer result in the formation of a single macroscopic molecule. At that point in the reaction, which is defined as gel point, the system loses fluidity and viscosity becomes very large. The onset of gelation, or gel point, is accompanied by a sudden increase in viscosity. This "infinite" sized polymer is called the gel or network, which does not dissolve in the solvent, but can swell in it. Background Gelation is promoted by gelling agents. Gelation can occur either by physical linking or by chemical crosslinking. While the physical gels involve physical bonds, chemical gelation involves covalent bonds. The first quantitative theories of chemical gelation w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oligomer

In chemistry and biochemistry, an oligomer () is a molecule that consists of a few repeating units which could be derived, actually or conceptually, from smaller molecules, monomers.Quote: ''Oligomer molecule: A molecule of intermediate relative molecular mass, the structure of which essentially comprises a small plurality of units derived, actually or conceptually, from molecules of lower relative molecular mass.'' The name is composed of Greek elements '' oligo-'', "a few" and '' -mer'', "parts". An adjective form is ''oligomeric''. The oligomer concept is contrasted to that of a polymer, which is usually understood to have a large number of units, possibly thousands or millions. However, there is no sharp distinction between these two concepts. One proposed criterion is whether the molecule's properties vary significantly with the removal of one or a few of the units. An oligomer with a specific number of units is referred to by the Greek prefix denoting that number, wi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oligomers

In chemistry and biochemistry, an oligomer () is a molecule that consists of a few repeating units which could be derived, actually or conceptually, from smaller molecules, monomers.Quote: ''Oligomer molecule: A molecule of intermediate relative molecular mass, the structure of which essentially comprises a small plurality of units derived, actually or conceptually, from molecules of lower relative molecular mass.'' The name is composed of Greek elements '' oligo-'', "a few" and '' -mer'', "parts". An adjective form is ''oligomeric''. The oligomer concept is contrasted to that of a polymer, which is usually understood to have a large number of units, possibly thousands or millions. However, there is no sharp distinction between these two concepts. One proposed criterion is whether the molecule's properties vary significantly with the removal of one or a few of the units. An oligomer with a specific number of units is referred to by the Greek prefix denoting that number, wit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dibenzoyl Peroxide

Benzoyl peroxide is a chemical compound (specifically, an organic peroxide) with structural formula , often abbreviated as (BzO)2. In terms of its structure, the molecule can be described as two benzoyl (, Bz) groups connected by a peroxide (). It is a white granular solid with a faint odour of benzaldehyde, poorly soluble in water but soluble in acetone, ethanol, and many other organic solvents. Benzoyl peroxide is an oxidizer, but it is principally used as in the production of polymers. Benzoyl peroxide is mainly used in production of plastics and for bleaching flour, hair, plastics and textiles. Synthesis, structure, and chemical reactivity The original 1858 synthesis by Liebig reacted benzoyl chloride with barium peroxide, a reaction described by the following idealized equation: : Benzoyl peroxide is usually prepared by treating hydrogen peroxide with benzoyl chloride under alkaline conditions. : As in many other peroxides, the C-O-O-C linkage has a dihedra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

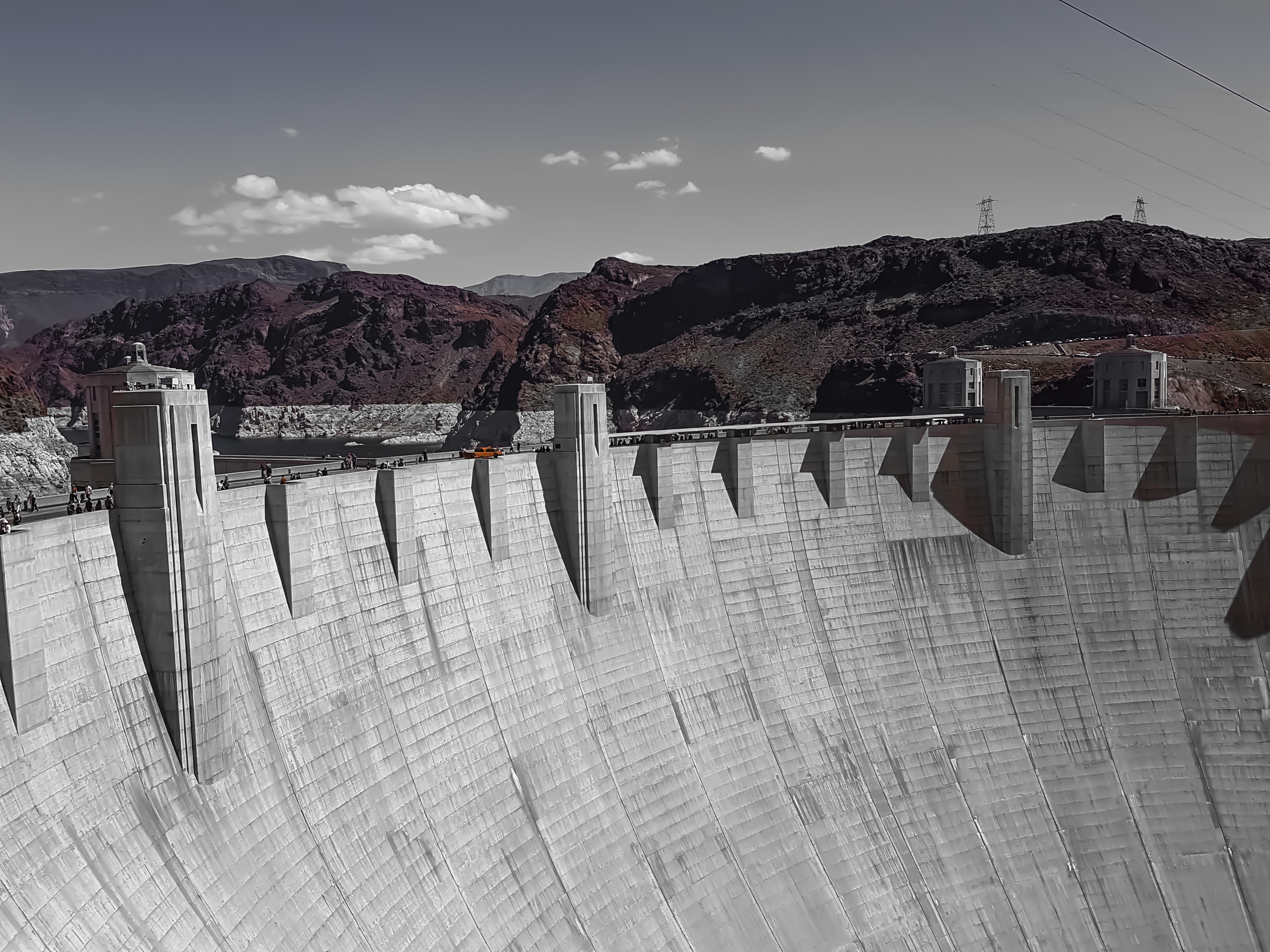

Concrete

Concrete is a composite material composed of fine and coarse aggregate bonded together with a fluid cement (cement paste) that hardens (cures) over time. Concrete is the second-most-used substance in the world after water, and is the most widely used building material. Its usage worldwide, ton for ton, is twice that of steel, wood, plastics, and aluminum combined. Globally, the ready-mix concrete industry, the largest segment of the concrete market, is projected to exceed $600 billion in revenue by 2025. This widespread use results in a number of environmental impacts. Most notably, the production process for cement produces large volumes of greenhouse gas emissions, leading to net 8% of global emissions. Other environmental concerns include widespread illegal sand mining, impacts on the surrounding environment such as increased surface runoff or urban heat island effect, and potential public health implications from toxic ingredients. Significant research and development is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drying Oil

A drying oil is an oil that hardens to a tough, solid film after a period of exposure to air, at room temperature. The oil hardens through a chemical reaction in which the components crosslink (and hence, polymerize) by the action of oxygen (not through the evaporation of water or other solvents). Drying oils are a key component of oil paint and some varnishes. Some commonly used drying oils include linseed oil, tung oil, poppy seed oil, perilla oil, and walnut oil. Their use has declined over the past several decades, as they have been replaced by alkyd resins and other binders. Since oxidation is the key to curing in these oils, those that are susceptible to chemical drying are often unsuitable for cooking, and are also highly susceptible to becoming rancid through autoxidation, the process by which fatty foods develop off-flavors. Rags, cloth, and paper saturated with drying oils may spontaneously combust (ignite) after a few hours as heat is released during the oxidation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallic Soap

A metallic soap is a metallic salt of a fatty acid. Theoretically, soaps can be made of any metal, although not all enjoy practical uses. Varying the metal can strongly affect the properties of the compound, particularly its solubility. Alkali, alkaline earth soaps Alkali metal and alkaline earth soaps are white solids. The most commonly encountered are traditional household soaps, which are the fatty acid salts of sodium (hard soap) and potassium (soft soap). Lithium soap or greases, such as lithium stearate, are insoluble in water and find use in lubricating grease. Calcium and magnesium soaps are most commonly encountered as soap scum but the pure materials have a variety of uses. Magnesium stearate and calcium stearate are used as excipients, lubricants, release agents, and food additives, with the later use being covered be the generic E numbers of E470b and E470 respectively. Other metal soaps Aluminium soaps are used as thickening agents, in the production of cosmetics ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Drying Agent

An oil drying agent, also known as siccative, is a coordination compound that accelerates ( catalyzes) the hardening of drying oils, often as they are used in oil-based paints. This so-called "drying" (actually a chemical reaction that produces an organic plastic) occurs through free-radical chemical crosslinking of the oils. The catalysts promote this free-radical autoxidation of the oils with air. Typical oil drying agents are derived from ions of cobalt, manganese, and iron, prepared as "salts" of lipophilic carboxylic acids such as naphthenic acids, in order to give them a soap-like chemical formula and make them oil-soluble. Varieties of drying agents In technical literature, oil drying agents, such as naphthenates, are described as salts, but they are probably also non-ionic coordination complexes with structures similar to basic zinc acetate. These catalysts were traditionally hydrocarbon carboxylate chelates of lead, but due to lead's toxicity, cobalt and other elements, s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer Chain

A polymer (; Greek '' poly-'', "many" + '' -mer'', "part") is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins that are fundamental to biological structure and function. Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. Their consequently large molecular mass, relative to small molecule compounds, produces unique physical properties including toughness, high elasticity, viscoelasticity, and a tendency to form amorphous and semicrystalline structures rather than crystals. The term "polymer" derives from the Greek word πολύς (''polus'', meaning "many, much") and μέρος (''meros'', meaning " ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sulfur Vulcanization

Sulfur vulcanization is a chemical process for converting natural rubber or related polymers into materials of varying hardness, elasticity, and mechanical durability by heating them with sulfur or sulfur-containing compounds. Sulfur forms cross-linking bridges between sections of polymer chains which affects the mechanical and electronic properties. Many products are made with vulcanized rubber, including tires, shoe soles, hoses, and conveyor belts. The term is derived from Vulcan, the Roman god of fire. The main polymers subjected to sulfur vulcanization are polyisoprene (natural rubber, NR), polybutadiene rubber (BR) and styrene-butadiene rubber (SBR), and ethylene propylene diene monomer rubber ( EPDM rubber). All of these materials contain alkene groups adjacent to methylene groups. Other specialty rubbers may also be vulcanized, such as nitrile rubber (NBR) and butyl rubber (IIR). Vulcanization, in common with the curing of other thermosetting polymers, is generally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.png)