|

Continuous Production

Continuous production is a flow production method used to manufacture, produce, or process materials without interruption. Continuous production is called a continuous process or a continuous flow process because the materials, either dry bulk or fluids that are being processed are continuously in motion, undergoing chemical reactions or subject to mechanical or heat treatment. Continuous processing is contrasted with batch production. Continuous usually means operating 24 hours per day, seven days per week with infrequent maintenance shutdowns, such as semi-annual or annual. Some chemical plants can operate for more than one to two years without a shutdown. Blast furnaces can run from four to ten years without stopping. Common processes Some common continuous processes are the following: * Oil refining *Chemicals * Synthetic fibers *Fertilizers * Pulp and paper *Blast furnace (iron) *Metal smelting *Power stations * Natural gas processing *Sanitary waste water treatme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flow Production

Flow may refer to: Science and technology * Fluid flow, the motion of a gas or liquid * Flow (geomorphology), a type of mass wasting or slope movement in geomorphology * Flow (mathematics), a group action of the real numbers on a set * Flow (psychology), a mental state of being fully immersed and focused * Flow, a spacecraft of NASA's GRAIL program Computing * Flow network, graph-theoretic version of a mathematical flow * Flow analysis * Calligra Flow, free diagramming software * Dataflow, a broad concept in computer systems with many different meanings * Microsoft Flow (renamed to Power Automate in 2019), a workflow toolkit in Microsoft Dynamics * Neos Flow, a free and open source web application framework written in PHP * webMethods Flow, a graphical programming language * FLOW (programming language), an educational programming language from the 1970s * Flow (web browser), a web browser with a proprietary rendering engine Arts, entertainment and media * ''Flow'' (journa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotary Kiln

A rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. Materials produced using rotary kilns include: * Cement kiln, Cement * Lime kiln, Lime * Refractory, Refractories * Metakaolin * Titanium dioxide * Aluminium oxide, Alumina * Vermiculite * Iron ore pellets They are also used for roasting (metallurgy), roasting a wide variety of sulfide ores prior to metal extraction. Principle of operation The kiln is a cylindrical vessel, inclined slightly from the horizontal, which is rotated slowly about its longitudinal axis. The process feedstock is fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down toward the lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln, sometimes in the same direction as the process material (co-current), but usually in the opposite direction (counter-current). The hot gases may be generated in an ext ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going from hand production methods to machines, new chemical manufacturing and iron production processes, the increasing use of steam power and water power, the development of machine tools and the rise of the mechanized factory system. Output greatly increased, and a result was an unprecedented rise in population and in the rate of population growth. Textiles were the dominant industry of the Industrial Revolution in terms of employment, value of output and capital invested. The textile industry was also the first to use modern production methods. The Industrial Revolution began in Great Britain, and many of the technological and architectural innovations were of British origin. By the mid-18th century, Britain was the world's leadin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

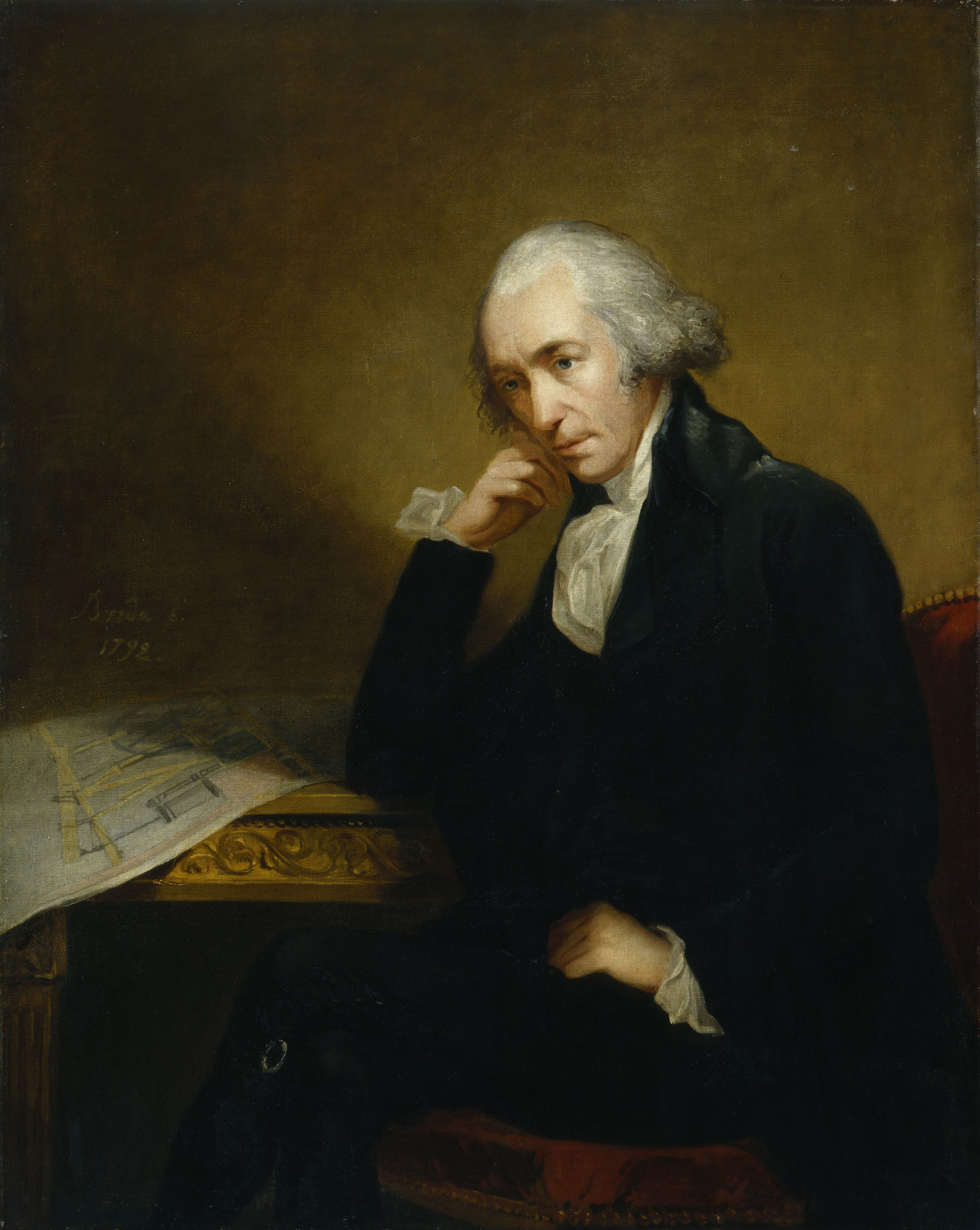

Richard Arkwright

Sir Richard Arkwright (23 December 1732 – 3 August 1792) was an English inventor and a leading entrepreneur during the early Industrial Revolution. He is credited as the driving force behind the development of the spinning frame, known as the water frame after it was adapted to use water power; and he patented a rotary carding engine to convert raw cotton to 'cotton lap' prior to spinning. He was the first to develop factories housing both mechanised carding and spinning operations. Arkwright's achievement was to combine power, machinery, semi-skilled labour and the new raw material of cotton to create mass-produced yarn. His organisational skills earned him the accolade "father of the modern industrial factory system," notably through the methods developed in his mill at Cromford, Derbyshire (now preserved as part of the Derwent Valley Mills World Heritage Site). Life and family Richard Arkwright was born in Preston, Lancashire, England on 23 December 1732, the youn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cromford Mill

Cromford Mill is the world's first water-powered cotton spinning mill, developed by Richard Arkwright in 1771 in Cromford, Derbyshire, England. The mill structure is classified as a Grade I listed building. It is now the centrepiece of the Derwent Valley Mills UNESCO World Heritage Site, and is a multi-use visitor centre with shops, galleries, restaurants and cafes. History Following the invention of the flying shuttle for weaving cotton in 1733, the demand for spun cotton increased enormously in England. Machines for carding and spinning had already been developed but were inefficient. Spun cotton was also produced by means of the spinning jenny but was insufficiently strong to form the warp of a fabric, for which it was the practice to use linen thread, producing a type of cloth known as fustian. In 1769, Richard Arkwright patented a water frame to use the extra power of a water mill after he had set up a horse-powered mill in Nottingham. He chose the site at Cromford beca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pig Iron

Pig iron, also known as crude iron, is an intermediate product of the iron industry in the production of steel which is obtained by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silica and other constituents of dross, which makes it brittle and not useful directly as a material except for limited applications. The traditional shape of the molds used for pig iron ingots is a branching structure formed in sand, with many individual ingots at right angles to a central channel or "runner", resembling a litter of piglets being nursed by a sow. When the metal had cooled and hardened, the smaller ingots (the "pigs") were simply broken from the runner (the "sow"), hence the name "pig iron". As pig iron is intended for remelting, the uneven size of the ingots and the inclusion of small amounts of sand cause only insignificant problems considering the ease of casting and handling them. History Smelting and producing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blast Furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheric pressure. In a blast furnace, fuel (coke (fuel), coke), ores, and Flux (metallurgy), flux (limestone) are continuously supplied through the top of the furnace, while a hot blast of air (sometimes with oxygen enrichment) is blown into the lower section of the furnace through a series of pipes called tuyeres, so that the #Process engineering and chemistry, chemical reactions take place throughout the furnace as the material falls downward. The end products are usually molten metal and slag phases tapped from the bottom, and waste gases (flue gas) exiting from the top of the furnace. The downward flow of the ore along with the flux in contact with an upflow of hot, carbon monoxide-rich combustion gases is a countercurrent exchange and chemical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Control

An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. It is implemented widely in industries such as automotive, mining, dredging, oil refining, pulp and paper manufacturing, chemical processing and power generating plants. There is a wide range of size, type and complexity, but it enables a small number of operators to manage complex processes to a high degree of consistency. The development of large industrial process control systems was instrumental in enabling the design of large high volume and complex processes, which could not be otherwise economically or safely operated. The applications can range from controlling the temperature and level of a single process vessel, to a complete chemical processing plant with several thousand control loops. History Early process control breakthr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shift Work

Shift work is an employment practice designed to make use of, or provide service across, all 24 hours of the clock each day of the week (often abbreviated as ''24/7''). The practice typically sees the day divided into shifts, set periods of time during which different groups of workers perform their duties. The term "shift work" includes both long-term night shifts and work schedules in which employees change or rotate shifts. In medicine and epidemiology, shift work is considered a risk factor for some health problems in some individuals, as disruption to circadian rhythms may increase the probability of developing cardiovascular disease, cognitive impairment, diabetes, altered body composition and obesity, among other conditions. History The shift work system in modern industrial manufacturing originated in the late 18th century. In 1867, Karl Marx wrote on the shift work system in ''Capital, Volume 1'': Capitalist production therefore drives, by its inherent nature, towa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

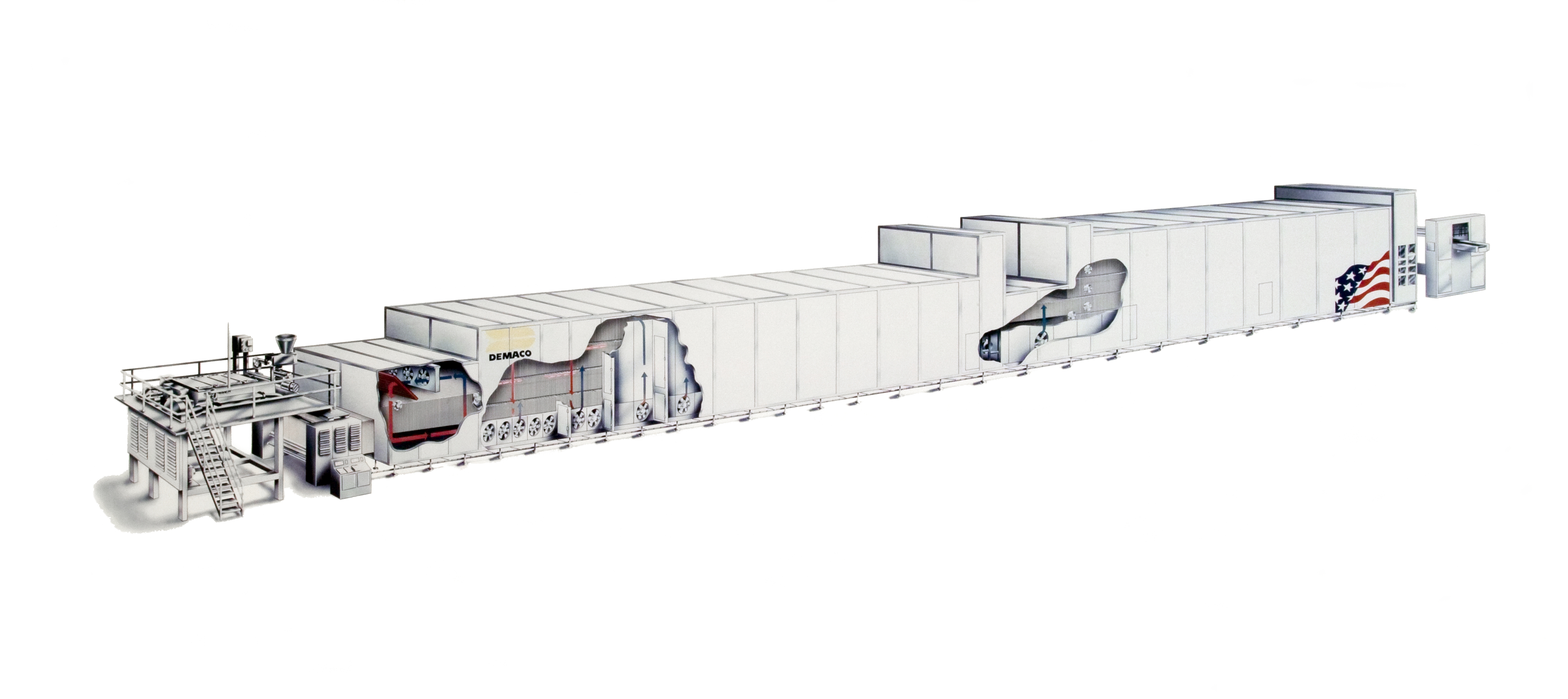

Dry Pasta Line

Dry or dryness most often refers to: * Lack of rainfall, which may refer to **Arid regions **Drought * Dry or dry area, relating to legal prohibition of selling, serving, or imbibing alcoholic beverages * Dry humor, deadpan * Dryness (medical) * Dryness (taste), the lack of sugar in a drink, especially an alcoholic one * Dry direct sound without reverberation Dry or DRY may also refer to: Places * Dry Brook (other), various rivers * Dry Creek (other), various rivers and towns * Dry, Loiret, a commune of the Loiret ''département'' in France * Dry River (other), various rivers and towns Art, entertainment, and media Film * ''Dry'' (2014 film), a Nigerian film directed by Stephanie Linus * ''Dry'' (2022 film), an Italian film directed by Paolo Virzì * ''The Dry'' (film), a 2020 film based on the novel by Jane Harper Literature * ''Dry'' (memoir), a 2003 memoir by Augusten Burroughs * ''The Dry'' (novel), a 2016 novel by Jane Harper Music * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Float Glass

Float glass is a sheet of glass made by floating molten glass on a bed of molten metal, typically tin, although lead and other various low-melting-point alloys were used in the past. This method gives the sheet uniform thickness and very flat surfaces. Modern windows are made from float glass. Most float glass is soda-lime glass, although relatively minor quantities of specialty borosilicate and flat panel display glass are also produced using the float glass process. The float glass process is also known as the Pilkington process, named after the British glass manufacturer Pilkington, which pioneered the technique in the 1950s at their production site in St Helens, Merseyside. History Until the 16th century, window glass or other flat glass was generally cut from large discs (or rondels) of crown glass. Larger sheets of glass were made by blowing large cylinders which were cut open and flattened, then cut into panes. Most window glass in the early 19th century was made usi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material in existence and is behind only water as the planet's most-consumed resource. Cements used in construction are usually inorganic, often lime or calcium silicate based, which can be characterized as hydraulic or the less common non-hydraulic, depending on the ability of the cement to set in the presence of water (see hydraulic and non-hydraulic lime plaster). Hydraulic cements (e.g., Portland cement) set and become adhesive through a chemical reaction between the dry ingredients and water. The chemical reaction results in mineral hydrates that are not very water-soluble and so are quite durable ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_and_her_daughter_Mary_Anne%2C_by_Joseph_Wright_of_Derby.jpg)