|

Cleanroom Suitability

{{short description, Metrics Cleanroom suitability describes the suitability of a machine, operating utility, material, etc. for use in a cleanroom, where air cleanliness and other parameters are controlled by way of technical regulations in accordance with ISO 14644. Cleanroom suitability is a subdomain of cleanliness suitability and primarily describes the particle emission behavior of a machine or operating utility (test piece). Testing The aim of cleanroom suitability tests is to determine the suitability of machines and operating utilities (air conditioning, venting, etc.) for use in cleanrooms. The tests must be carried out using measurement techniques as particle emission behavior cannot be adequately assessed by the naked eye or similar means. No metrological tests are required if there are obvious flaws in machines and operating utilities, such as rust or the presence of porous or completely unsuitable materials (wood, etc.). Tests to assess the cleanroom suitability ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cleanroom

A cleanroom or clean room is an engineered space, which maintains a very low concentration of airborne particulates. It is well isolated, well-controlled from contamination, and actively cleansed. Such rooms are commonly needed for scientific research, and in industrial production for all nanoscale processes, such as semiconductor manufacturing. A cleanroom is designed to keep everything from dust, to airborne organisms, or vaporised particles, away from it, and so from whatever material is being handled inside it. The other way around, a cleanroom can also help keep materials escaping from it. This is often the primary aim in hazardous biology and nuclear work, in pharmaceutics and in virology. Cleanrooms typically come with a cleanliness level quantified by the number of particles per cubic meter at a predetermined molecule measure. The ambient outdoor air in a typical urban area contains 35,000,000 particles for each cubic meter in the size range 0.5 μm and bigger, equ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ISO 14644-1

ISO 14644 Standards were first formed from the US Federal Standard 209E Airborne Particulate Cleanliness Classes in Cleanrooms and Clean Zones. The need for a single standard for cleanroom classification and testing was long felt. After ANSI and IEST petitioned to ISO for new standards, the first document of ISO 14644 was published in 1999, ISO 14644-1. In 2000, ISO 14644-2 was published, which began the process of FED-STD-209E being canceled. On November 29, 2001, the document was canceled and superseded by ISO 14644-1 and ISO 14644-2. ;ISO 14644 is now composed of: *ISO 14644-1: Classification of air cleanliness *ISO/DIS 14644-1.2(2014): Classification of air cleanliness by particle concentration *ISO 14644-2: Specifications for testing and monitoring to prove continued compliance with ISO 14644-1 *ISO/DIS 14644-2.2(2014): Monitoring to provide evidence of cleanroom performance related to air cleanliness by particle concentration *ISO 14644-3: Test Methods *ISO 14644-4: Desi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cleanliness Suitability

Cleanliness suitability describes the suitability of operating materials and ventilation and air conditioning components for use in cleanrooms where the air cleanliness and other parameters are controlled by way of technical regulations. Tests are carried out to determine this.VDI 2083, Part 17: Cleanroom technology – Cleanroom and cleanliness suitability of materials Trends such as the miniaturization of structures as well as increased levels of reliability in technology, research and science require controlled “clean” manufacturing environments. The task of such environments is to minimize influences which could damage the products concerned. The cleanroom environments created by filtering the air were originally developed for the fields of microelectronics and microsystem technology but are now used in a wide range of other high technology sectors such as photovoltaics and the automotive industry. Depending upon the industry and process concerned, different factors may have ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laminar Flow

In fluid dynamics, laminar flow is characterized by fluid particles following smooth paths in layers, with each layer moving smoothly past the adjacent layers with little or no mixing. At low velocities, the fluid tends to flow without lateral mixing, and adjacent layers slide past one another like playing cards. There are no cross-currents perpendicular to the direction of flow, nor eddies or swirls of fluids. In laminar flow, the motion of the particles of the fluid is very orderly with particles close to a solid surface moving in straight lines parallel to that surface. Laminar flow is a flow regime characterized by high momentum diffusion and low momentum convection. When a fluid is flowing through a closed channel such as a pipe or between two flat plates, either of two types of flow may occur depending on the velocity and viscosity of the fluid: laminar flow or turbulent flow. Laminar flow occurs at lower velocities, below a threshold at which the flow becomes turbulent. Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

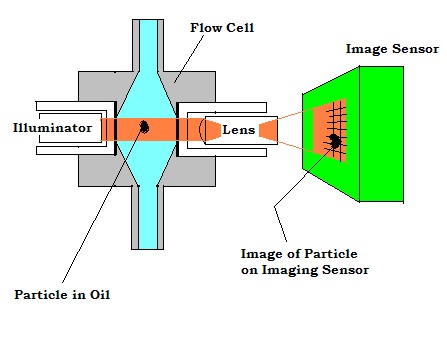

Particle Counter

A particle counter is used for monitoring and diagnosing particle contamination within specific clean media, including air, water and chemicals. Particle counters are used in a variety of applications in support of clean manufacturing practices, industries include: electronic components and assemblies, pharmaceutical drug products and medical devices, and industrial technologies such as oil and gas. Technology Particle counters function primarily using the principles of light scattering, although other technologies may also be employed. Light scattering by particles use instrumentation comprising a high-intensity light source (a laser), a controlled media flow (air, gas or liquid) and highly sensitive light-gathering detectors (a photo detector). Laser optical particle counters employ five major systems: #Lasers and optics: A laser operates on a single wavelength, so the light source is consistent with constant power output to illuminate the particle sampling region. #Control ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |