|

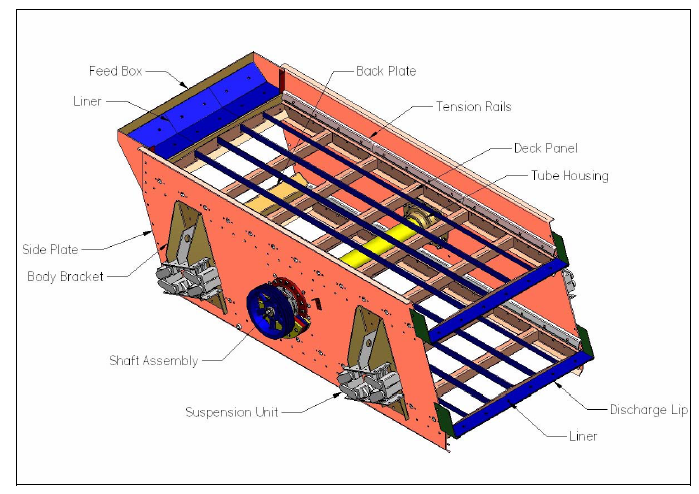

Circle-throw Vibrating Machine

A circle-throw vibrating machine is a Mechanical screening, screening machine employed in processes involving particle separation. In particle processes screening refers to separation of larger from smaller particles in a given feed, using only the materials' physical properties. Circle throw machines have simple structure with high screening efficiency and volume. However it has limitations on the types of feed that can be processed smoothly. Some characteristics of circle-throw machines, such as frequency, vibration amplitude and angle of incline deck also affect output. Applications They are widely used for screening quarry stone stock and classifying products in mining, sand, gold, energy and chemical industrial processes. The targeted substance is predominantly finer particles, which can then be directed into a separation unit, such as a hydrocyclone or are materials that can be removed and used. Removed materials are often formed intentionally and are classified by their sha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Screening

Mechanical screening, often just called screening, is the practice of taking granulated or crushed ore material and separating it into multiple grades by particle size. This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling. A method of separating solid particles according to size alone is called screening. General categories Screening falls under two general categories: dry screening, and wet screening. From these categories, screening separates a flow of material into grades, these grades are then either further processed to an intermediary product or a finished product. Additionally, the machines can be categorized into a moving screen and static screen machines, as well as by whether the screens are horizontal or inclined. Applications The mining and mineral processing industry uses screening for a variety of processing applications. For example, after mining the minerals, the materia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanics

Mechanics (from Ancient Greek: μηχανική, ''mēkhanikḗ'', "of machines") is the area of mathematics and physics concerned with the relationships between force, matter, and motion among physical objects. Forces applied to objects result in displacements, or changes of an object's position relative to its environment. Theoretical expositions of this branch of physics has its origins in Ancient Greece, for instance, in the writings of Aristotle and Archimedes (see History of classical mechanics and Timeline of classical mechanics). During the early modern period, scientists such as Galileo, Kepler, Huygens, and Newton laid the foundation for what is now known as classical mechanics. As a branch of classical physics, mechanics deals with bodies that are either at rest or are moving with velocities significantly less than the speed of light. It can also be defined as the physical science that deals with the motion of and forces on bodies not in the quantum rea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states: * no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or any other element to be added to obtain a desired alloying effect; * the specified minimum for copper does not exceed 0.40%; * or the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65%; silicon 0.60%; copper 0.60%. The term ''carbon steel'' may also be used in reference to steel which is not stainless steel; in this use carbon steel may include alloy steels. High carbon steel has many different uses such as milling machines, cutting tools (such as chisels) and high strength wires. These applications require a much finer microstructure, which improves the toughness. Carbon steel is a popular met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Revolutions Per Minute

Revolutions per minute (abbreviated rpm, RPM, rev/min, r/min, or with the notation min−1) is a unit of rotational speed or rotational frequency for rotating machines. Standards ISO 80000-3:2019 defines a unit of rotation as the dimensionless unit equal to 1, which it refers to as a revolution, but does not define the revolution as a unit. It defines a unit of rotational frequency equal to s−1. The superseded standard ISO 80000-3:2006 did however state with reference to the unit name 'one', symbol '1', that "The special name revolution, symbol r, for this unit is widely used in specifications on rotating machines." The International System of Units (SI) does not recognize rpm as a unit, and defines the unit of frequency, Hz, as equal to s−1. :\begin 1~&\text &&=& 60~&\text \\ \frac~&\text &&=& 1~&\text \end A corresponding but distinct quantity for describing rotation is angular velocity, for which the SI unit is the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Capital Cost

Capital costs are fixed, one-time expenses incurred on the purchase of land, buildings, construction, and equipment used in the production of goods or in the rendering of services. In other words, it is the total cost needed to bring a project to a commercially operable status. Whether a particular cost is capital or not depend on many factors such as accounting, tax laws, and materiality. Categories Capital costs include expenses for tangible goods such as the purchase of plants and machinery, as well as expenses for intangibles assets such as trademarks and software development. Capital costs are not limited to the initial construction of a factory or other business. Namely, the purchase of a new machine to increase production and last for years is a capital cost. Capital costs do not include labor costs (they do include construction labor). Unlike operating costs, capital costs are one-time expenses but payment may be spread out over many years in financial reports a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Damping Ratio

Damping is an influence within or upon an oscillatory system that has the effect of reducing or preventing its oscillation. In physical systems, damping is produced by processes that dissipate the energy stored in the oscillation. Examples include viscous drag (a liquid's viscosity can hinder an oscillatory system, causing it to slow down; see viscous damping) in mechanical systems, resistance in electronic oscillators, and absorption and scattering of light in optical oscillators. Damping not based on energy loss can be important in other oscillating systems such as those that occur in biological systems and bikes (ex. Suspension (mechanics)). Not to be confused with friction, which is a dissipative force acting on a system. Friction can cause or be a factor of damping. The damping ratio is a dimensionless measure describing how oscillations in a system decay after a disturbance. Many systems exhibit oscillatory behavior when they are disturbed from their position of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bearing (mechanical)

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may ''prevent'' a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts. Rotary bearings hold rotating components such as shafts or axles within mechanical systems, and transfer axial and radial loads from the source of the load to the structure supporting it. The simplest form of bearing, the '' plain bearing'', consists of a shaft rotating in a hole. Lubrication is used to reduce friction. In the ''ball bearing'' and ''roller bearing'', to reduce sli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |