|

Ceramic Plate

A ballistic plate, also known as an armour plate, is a protective armoured plate inserted into a carrier or bulletproof vest, that can be used stand-alone, or in conjunction with other armour. "Hard armour" usually denotes armour that uses ballistic plates. It serves to defeat higher threats, and may be considered as a form of applique armour. It is usually inserted into the front and back, with side inserts also sometimes used. There are also plates for other regions, such as the shoulders, lap, and throat. Dimensions and sizing Ballistic plates can be found in a variety of sizes and shapes. In the industry, armour plate shapes are common referred to as a cut, in reference to how the strike face must be cut from the material. The most common are the: * SAPI Cut, a rectangle with two sloped cuts on the top two corners, the name being derived from the SAPI armour plate. Similar, but with larger cuts, is the Shooter's Cut. * Swimmer's Cut, similar to a stretched trapezoid on to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bulletproof Vest

A bulletproof vest, also known as a ballistic vest or a bullet-resistant vest, is an item of body armor that helps absorb the impact and reduce or stop penetration to the torso from firearm-fired projectiles and fragmentation from explosions. The vest may come in a soft form, as worn by many police officers, prison guards, security guards, and some private citizens, used to protect against stabbing attacks or light projectiles, using metallic or para-aramid components. Soldiers, police tactical units, marines, and special operations forces wear hard armors, either in conjunction with soft armor or alone, to protect against rifle ammunition or fragmentation. History Early modern era In 1538, Francesco Maria della Rovere commissioned Filippo Negroli to create a bulletproof vest. In 1561, Maximilian II, Holy Roman Emperor is recorded as testing his armor against gun-fire. Similarly, in 1590 Sir Henry Lee expected his Greenwich armor to be "pistol proof". Its actual effectiveness ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Small Arms Protective Insert

The Small Arms Protective Insert (SAPI) is a ceramic ballistic plate used by the United States Armed Forces. It was first used in the Interceptor Body Armor, a ballistic vest. It is now also used in the Improved Outer Tactical Vest as well as the Modular Tactical Vest, in addition to commercially available "plate carriers". The Kevlar Interceptor vest itself is designed to stop projectiles up to and including 9×19mm Parabellum submachine gun rounds, in addition to fragmentation. To protect against higher-velocity rifle rounds, SAPI plates are needed. ESAPI In May 2005, the U.S. Armed Forces began replacing the standard Small Arms Protective Insert plates with the Enhanced Small Arms Protective Insert (ESAPI). An ESAPI provides protection from .30-06 Springfield M2 armor-piercing (AP) with a steel penetrator in accordance with the NIJ Level IV standard, but costs about $600 per plate, 50% more than SAPI plates. They are produced by Ceradyne, BAE Systems, and ArmorWorks Ente ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick. The earliest ceramics made by humans were pottery objects (''pots,'' ''vessels or vases'') or figurines made from clay, either by itself or mixed with other materials like silica, hardened and sintered in fire. Later, ceramics were glazed and fired to create smooth, colored surfaces, decreasing porosity through the use of glassy, amorphous ceramic coatings on top of the crystalline ceramic substrates. Ceramics now include domestic, industrial and building products, as well as a wide range of materials developed for use in advanced ceramic engineering, such as in semiconductors. The word "'' ceramic''" comes from the Greek word (), "of pottery" or "for pottery", from (), "potter's clay, tile, pottery". The earliest kno ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceramic Armor

Ceramic armor is armor used by armored vehicles and in personal armor to resist projectile penetration through high hardness and compressive strength. In its most basic form, it consists of two primary components: A ceramic layer on the outer surface, called the "strike face," backed up by a ductile fiber reinforced plastic composite or metal layer. The role of the ceramic is to (1) fracture the projectile or deform the projectile nose upon impact, (2) erode and slow down the projectile remnant as it penetrates the shattered ceramic layer, and (3) distribute the impact load over a larger area which can be absorbed by ductile polymer or metallic backings. Ceramics are often used where light weight is important, as they weigh less than metal alloys for a given degree of resistance. The most common materials are alumina, boron carbide, and, to a lesser extent, silicon carbide. History Tests as early as 1918 demonstrated the potential of ceramic armor; Major Neville Monroe-Hop ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boron Carbide

Boron carbide (chemical formula approximately B4C) is an extremely hard boron–carbon ceramic, a covalent material used in tank armor, bulletproof vests, engine sabotage powders, as well as numerous industrial applications. With a Vickers hardness of >30 GPa, it is one of the hardest known materials, behind cubic boron nitride and diamond. History Boron carbide was discovered in the 19th century as a by-product of reactions involving metal borides, but its chemical formula was unknown. It was not until the 1930s that the chemical composition was estimated as B4C. Controversy remained as to whether or not the material had this exact 4:1 stoichiometry, as, in practice the material is always slightly carbon-deficient with regard to this formula, and X-ray crystallography shows that its structure is highly complex, with a mixture of C-B-C chains and B12 icosahedra. These features argued against a very simple exact B4C empirical formula. Because of the B12 structural unit, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon Carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder and crystal since 1893 for use as an abrasive. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics that are widely used in applications requiring high endurance, such as car brakes, car clutches and ceramic plates in bulletproof vests. Large single crystals of silicon carbide can be grown by the Lely method and they can be cut into gems known as synthetic moissanite. Electronic applications of silicon carbide such as light-emitting diodes (LEDs) and Cat's whisker detector, detectors in early radios were first demonstrated around 1907. SiC is used in semiconductor electronics devices that operate at high temperatures or high voltages, or both. Natural occurrence Naturally occurring moissanite is found in only minut ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ceradyne

Ceradyne, Incorporated is a wholly owned subsidiary of the British company, Avon Rubber. Ceradyne, Inc. is a manufacturer of advanced ceramic systems and components and involved in many technical industries including nuclear power, oil and gas, solar energy, automotive, and defense. It is traded on the NASDAQ Stock Market. Background Ceradyne was founded in 1967 and in late 2004, the company added new product lines by acquiring ESK Ceramics of Kempten, Germany. In addition to producing ceramic components for industrial processes such as silicon foundries and ceramic fuel pellets for nuclear reactors, Ceradyne researched and produced varieties of ballistic armour for both personnel and vehicles. The ceramic armor was lighter than regular steel plate armor facilitating greater mobility. On September 16, 2007, the company was selling 25,000 sets of armor a month to the Pentagon.In December 2007, Ceradyne's lightweight armor was approved by the Army for use on military vehicles. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

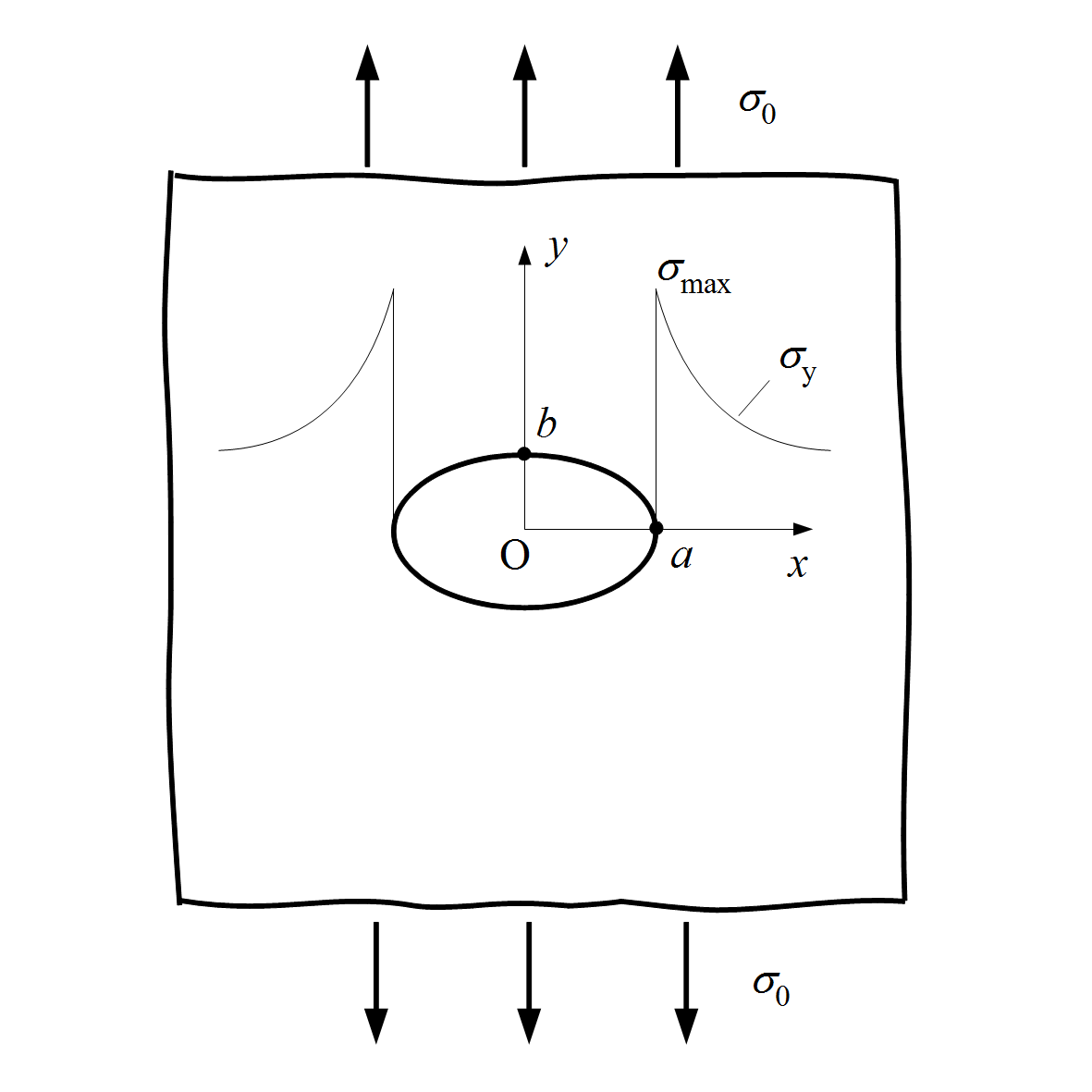

Stress Concentration

In solid mechanics, a stress concentration (also called a stress raiser or a stress riser) is a location in an object where the stress is significantly greater than the surrounding region. Stress concentrations occur when there are irregularities in the geometry or material of a structural component that cause an interruption to the flow of stress. This arises from such details as holes, grooves, notches and fillets. Stress concentrations may also occur from accidental damage such as nicks and scratches. The degree of concentration of a discontinuity under typically tensile loads can be expressed as a non-dimensional stress concentration factor K_t, which is the ratio of the highest stress to the nominal far field stress. For a circular hole in an infinite plate, K_t = 3. The stress concentration factor should not be confused with the stress intensity factor, which is used to define the effect of a crack on the stresses in the region around a crack tip. For ductile materials ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultra High Molecular Weight Polyethylene

Ultra-high-molecular-weight polyethylene (UHMWPE, UHMW) is a subset of the thermoplastic polyethylene. Also known as high-modulus polyethylene, (HMPE), it has extremely long chains, with a molecular mass usually between 3.5 and 7.5 million amu. The longer chain serves to transfer load more effectively to the polymer backbone by strengthening intermolecular interactions. This results in a very tough material, with the highest impact strength of any thermoplastic presently made. UHMWPE is odorless, tasteless, and nontoxic. It embodies all the characteristics of high-density polyethylene (HDPE) with the added traits of being resistant to concentrated acids and alkalis, as well as numerous organic solvents. It is highly resistant to corrosive chemicals except oxidizing acids; has extremely low moisture absorption and a very low coefficient of friction; is self-lubricating (see boundary lubrication); and is highly resistant to abrasion, in some forms being 15 times more resistant to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

UHMWPE

Ultra-high-molecular-weight polyethylene (UHMWPE, UHMW) is a subset of the thermoplastic polyethylene. Also known as high-modulus polyethylene, (HMPE), it has extremely long chains, with a molecular mass usually between 3.5 and 7.5 million amu. The longer chain serves to transfer load more effectively to the polymer backbone by strengthening intermolecular interactions. This results in a very tough material, with the highest impact strength of any thermoplastic presently made. UHMWPE is odorless, tasteless, and nontoxic. It embodies all the characteristics of high-density polyethylene (HDPE) with the added traits of being resistant to concentrated acids and alkalis, as well as numerous organic solvents. It is highly resistant to corrosive chemicals except oxidizing acids; has extremely low moisture absorption and a very low coefficient of friction; is self-lubricating (see boundary lubrication); and is highly resistant to abrasion, in some forms being 15 times more resistant to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Nanotube

A scanning tunneling microscopy image of a single-walled carbon nanotube Rotating single-walled zigzag carbon nanotube A carbon nanotube (CNT) is a tube made of carbon with diameters typically measured in nanometers. ''Single-wall carbon nanotubes'' (''SWCNTs'') are one of the allotropes of carbon, intermediate between fullerene cages and flat graphene, with diameters in the range of a nanometre. Although not made this way, single-wall carbon nanotubes can be idealized as cutouts from a two-dimensional Hexagonal tiling, hexagonal lattice of carbon atoms rolled up along one of the Bravais lattice vectors of the hexagonal lattice to form a hollow cylinder. In this construction, periodic boundary conditions are imposed over the length of this roll-up vector to yield a helical lattice of seamlessly bonded carbon atoms on the cylinder surface. ''Multi-wall carbon nanotubes'' (''MWCNTs'') consisting of nested single-wall carbon nanotubes weakly bound together by van der Waals ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |