|

Cage Nut

A cage nut or caged nut (also called a captive or clip nut) consists of a (usually square) nut in a spring steel cage which wraps around the nut. The cage has two wings that when compressed allow the cage to be inserted into the square holes, for example, in the mounting rails of equipment racks. When the wings are released, they hold the nut in position behind the hole. Cage nuts conforming to this description were patented in 1952 and 1953. This design requires insertion tools to install the cage nut into the hole. Newer designs featuring a squeeze-and-release tab allow for tool-less installation. The square-hole cage nut can be used wherever a square hole can be punched. An older type of captive-nut uses a spring clip that holds the nut and slides on the edge of a thin sheet. While this type of cage nut can only position the nut a fixed distance from the edge of a thin plate, it works equally well with square and round holes. A patent for such a nut was granted in 1946.George ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Threaded Insert

A threaded insert, also known as a threaded bushing, is a fastener element that is inserted into an object to add a threaded hole. They may be used to repair a stripped threaded hole, provide a durable threaded hole in a soft material, place a thread on a material too thin to accept it, mold or cast threads into a work piece thereby eliminating a machining operation, or simplify changeover from unified to metric threads or vice versa. Types Thread inserts come in many varieties, depending on the application. Threaded inserts for plastics are used in plastic materials and applied with thermal insertion or ultrasonic welding machines. Manufacturers of ready-to-assemble furniture often ship the parts with threaded inserts and other kinds of knock-down fasteners pre-installed. People who use sheet metal or sandwich panel or honeycomb sandwich-structured composite often install threaded inserts to spread shear, tension, and torque loads over a larger area of the material. Captiv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clip-on Nut

A clip-on nut, also known as a sheet metal nut or a speed nut (but this is ambiguous, see speed nut), is a type of nut designed to be clipped to sheet metal. It is a type of captive nut commonly made as a cage nut. Types They come in many forms based upon: where they clip on, shape, and type of thread. Each clip-on nut is designed for only a small range of sheet metal gauges (thicknesses). They are usually made from spring steel. G-nut A G-nut, or G-style nut, is shaped like a "G" and clips to the edge of a sheet metal object. It is different from all of the other types in that it is meant to clip over a small flange on the edge of the sheet metal. The threads are from an integrated nut that has a special boss to sit in a hole in the sheet metal. J-nut A J-nut is a nut that clips to the edge of the sheet metal. It is named after the way it is shaped; the thread is on the long side of the "J". The thread may either be of a speed nut form or have an integrated hex or square n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nut (hardware)

A nut is a type of fastener with a threaded hole. Nuts are almost always used in conjunction with a mating bolt to fasten multiple parts together. The two partners are kept together by a combination of their threads' friction (with slight elastic deformation), a slight stretching of the bolt, and compression of the parts to be held together. In applications where vibration or rotation may work a nut loose, various locking mechanisms may be employed: lock washers, jam nuts, eccentric double nuts, specialist adhesive thread-locking fluid such as Loctite, safety pins ( split pins) or lockwire in conjunction with castellated nuts, nylon inserts (nyloc nut), or slightly oval-shaped threads. Square nuts, as well as bolt heads, were the first shape made and used to be the most common largely because they were much easier to manufacture, especially by hand. While rare today due to the reasons stated below for the preference of hexagonal nuts, they are occasionally used in some ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spring Steel

Spring steel is a name given to a wide range of steels used in the manufacture of different products, including swords, saw blades, springs and many more. These steels are generally low-alloy manganese, medium-carbon steel or high-carbon steel with a very high yield strength. This allows objects made of spring steel to return to their original shape despite significant deflection or twisting. Grades Many grades of steel can be hardened and tempered to increase elasticity and resist deformation; however, some steels are inherently more elastic than others: Applications * Applications include piano wire (also known as music wire) such as ASTM A228 (0.80–0.95% carbon), spring clamps, antennas, springs (e. g. vehicle coil springs or leaf springs), and s-tines. * Spring steel is commonly used in the manufacture of swords with rounded edges for training or stage combat, as well as sharpened swords for collectors and live combat. * Spring steel is one of the most popular m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Equipment Rack

A 19-inch rack is a standardized frame or enclosure for mounting multiple electronic equipment modules. Each module has a front panel that is wide. The 19 inch dimension includes the edges or "ears" that protrude from each side of the equipment, allowing the module to be fastened to the rack frame with screws or bolts. Common uses include computer servers, telecommunications equipment and networking hardware, audiovisual production gear, and scientific equipment. Overview and history Equipment designed to be placed in a rack is typically described as rack-mount, rack-mount instrument, a rack-mounted system, a rack-mount chassis, subrack, rack cabinet, rack-mountable, or occasionally simply shelf. The height of the electronic modules is also standardized as multiples of or one rack unit or U (less commonly RU). The industry-standard rack cabinet is 42U tall; however, 45U racks are also common. The term ''relay rack'' appeared first in the world of telephony. By 1911, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

19-inch Rack

A 19-inch rack is a standardized frame or enclosure for mounting multiple electronic equipment modules. Each module has a front panel that is wide. The 19 inch dimension includes the edges or "ears" that protrude from each side of the equipment, allowing the module to be fastened to the rack frame with screws or bolts. Common uses include computer servers, telecommunications equipment and networking hardware, audiovisual production gear, and scientific equipment. Overview and history Equipment designed to be placed in a rack is typically described as rack-mount, rack-mount instrument, a rack-mounted system, a rack-mount chassis, subrack, rack cabinet, rack-mountable, or occasionally simply shelf. The height of the electronic modules is also standardized as multiples of or one rack unit or U (less commonly RU). The industry-standard rack cabinet is 42U tall; however, 45U racks are also common. The term ''relay rack'' appeared first in the world of telephony. By 1911, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Unified Thread Standard

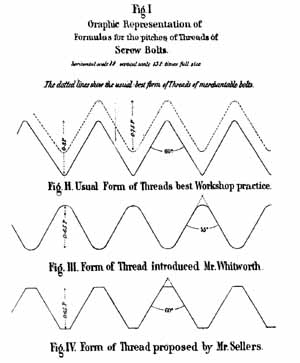

The Unified Thread Standard (UTS) defines a standard thread form and series—along with allowances, tolerances, and designations—for screw threads commonly used in the United States and Canada. It is the main standard for bolts, nuts, and a wide variety of other threaded fasteners used in these countries. It has the same 60° profile as the ISO metric screw thread, but the characteristic dimensions of each UTS thread (outer diameter and pitch) were chosen as an inch fraction rather than a millimeter value. The UTS is currently controlled by ASME/ANSI in the United States. Origins : ''See the "History of standardization" section of the screw thread article.'' Basic profile Each thread in the series is characterized by its major diameter ''D''maj and its pitch, ''P''. UTS threads consist of a symmetric V-shaped thread. In the plane of the thread axis, the flanks of the V have an angle of 60° to each other. The outermost and the innermost of the height ''H'' of the V-s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ISO Metric Screw Thread

The ISO metric screw thread is the most commonly used type of general-purpose screw thread worldwide. They were one of the first international standards agreed when the International Organization for Standardization (ISO) was set up in 1947. The "M" designation for metric screws indicates the nominal outer diameter of the screw thread, in millimetres. This is also referred to as the "major" diameter in the information below. It indicates the diameter of smooth-walled hole that a male thread (e.g. on a bolt) will pass through easily to create a well-located connection to an internally threaded component (e.g. a nut) on the other side. That is, an M6 screw has a nominal outer diameter of 6 millimetres and will therefore be a well-located, co-axial fit in a hole drilled to 6 mm diameter. Basic profile The design principles of ISO general-purpose metric screw threads ("M" series threads) are defined in international standard ISO 68-1. Each thread is characterized by its Screw ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)