|

Black Coal Equivalent

Black coal equivalent (BCE) is an export coal product derived from the Coldry Process, a patented coal upgrading technology operated by Environmental Clean Technologies Limited, in Victoria, Australia. The Coldry Process is applied to brown coal ( lignite) with a typical moisture content of 60 per cent by weight and transforms the coal into a densified coal product of equal or better calorific value (5,800 kcal/kg) to typical export quality black coal, with less ash and sulfur content. Black coal equivalent derived from brown coal is ostensibly a 'cleaner' burning coal fuel than most black coals. Overview Densified coal as a ''black coal equivalent'' product derived from brown coal was first discovered by R. B. Johns and colleagues at the Organic Chemistry laboratory at Melbourne University following observations made at the Maddingley Mine near Bacchus Marsh, Victoria. Johns and colleagues identified that a process of low-mechanical shear applied to brown coal mixed with a smal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coldry Process

Densified coal is the product of the Coldry Process coal upgrading technology that removes moisture from low-rank coals such as sub-bituminous and lignite/brown coal. The densification process raises the calorific value of low-rank coal to equal or exceed that of many export-grade black coals. Densified coal resulting from the Coldry Process is regarded as a black coal equivalent or replacement for black coal. The Coldry Process is a patented coal upgrading technology being developed in Victoria, Australia by Environmental Clean Technologies Limited based on 'brown coal densification'. It has been developed specifically to improve low-rank brown coal (lignite) and some forms of sub-bituminous coal by removing the majority of the naturally occurring moisture content; harden and densify the coal; raise the calorific value of the coal; and transform the coal into a stable (lower spontaneous combustion risk), exportable black coal equivalent product for use by black coal fired power g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bergius Process

The Bergius process is a method of production of liquid hydrocarbons for use as synthetic fuel by hydrogenation of high-volatile bituminous coal at high temperature and pressure. It was first developed by Friedrich Bergius in 1913. In 1931 Bergius was awarded the Nobel Prize in Chemistry for his development of high-pressure chemistry. Process The coal is finely ground and dried in a stream of hot gas. The dry product is mixed with heavy oil recycled from the process. A catalyst is typically added to the mixture. A number of catalysts have been developed over the years, including tungsten or molybdenum disulfide, tin or nickel oleate, and others. Alternatively, iron sulfide present in the coal may have sufficient catalytic activity for the process, which was the original Bergius process. The mixture is pumped into a reactor. The reaction occurs at between 400 and 500 °C and 20 to 70 MPa hydrogen pressure. The reaction produces heavy oils, middle oils, gasoline, and gases. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Leonardite

Leonardite is a soft waxy, black or brown, shiny, vitreous mineraloid that is easily soluble in alkaline solutions. It is an oxidation product of lignite, associated with near-surface mining. It is a rich source of humic acid (up to 90%) and is used as a soil conditioner, as a stabilizer for ion-exchange resins in water treatment, in the remediation of polluted environments and as a drilling additive.Hoffman, G.L., Nikols, D.J., Stuhec, S., Wilson, R.A. Evaluation of Leonardite (Humalite) Open File Report 1993-18, Resources of Alberta, Alberta Geological Survey It was named after A. G. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Karrick Process

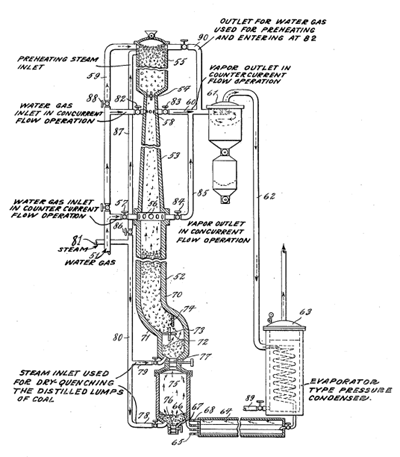

The Karrick process is a low-temperature carbonization (LTC) and pyrolysis process of carbonaceous materials. Although primarily meant for coal carbonization, it also could be used for processing of oil shale, lignite or any carbonaceous materials. These are heated at to in the absence of air to distill out synthetic fuels–unconventional oil and syngas. It could be used for a coal liquefaction as also for a semi-coke production. The process was the work of oil shale technologist Lewis Cass Karrick at the United States Bureau of Mines in the 1920s. History The Karrick process was invented by Lewis Cass Karrick in the 1920s. Although Karrick did not invent coal LTC as such, he perfected the existing technologies resulting the Karrick process. The retort used for the Karrick process based on the Nevada–Texas–Utah Retort, used for the shale oil extraction. In 1935, a Karrick LTC pilot plant was constructed in the coal research laboratory at the University of Utah. Comme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fischer–Tropsch Process

The Fischer–Tropsch process is a collection of chemical reactions that converts a mixture of carbon monoxide and hydrogen, known as syngas, into liquid hydrocarbons. These reactions occur in the presence of metal catalysts, typically at temperatures of and pressures of one to several tens of atmospheres. The process was first developed by Franz Fischer and Hans Tropsch at the Kaiser Wilhelm Institute for Coal Research in Mülheim an der Ruhr, Germany, in 1925. As a premier example of C1 chemistry, the Fischer–Tropsch process is an important reaction in both coal liquefaction and gas to liquids technology for producing liquid hydrocarbons. In the usual implementation, carbon monoxide and hydrogen, the feedstocks for FT, are produced from coal, natural gas, or biomass in a process known as gasification. The process then converts these gases into synthetic oil, synthetic lubrication oil and synthetic fuel. This process has received intermittent attention as a source of low-s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Orders Of Magnitude (specific Energy Density)

Specific energy or massic energy is energy per unit mass. It is also sometimes called gravimetric energy density, which is not to be confused with energy density, which is defined as energy per unit volume. It is used to quantify, for example, stored heat and other thermodynamic properties of substances such as specific internal energy, specific enthalpy, specific Gibbs free energy, and specific Helmholtz free energy. It may also be used for the kinetic energy or potential energy of a body. Specific energy is an intensive property, whereas energy and mass are extensive properties. The SI unit for specific energy is the joule per kilogram (J/kg). Other units still in use in some contexts are the kilocalorie per gram (Cal/g or kcal/g), mostly in food-related topics, watt hours per kilogram in the field of batteries, and the Imperial unit BTU per pound (Btu/lb), in some engineering and applied technical fields. Kenneth E. Heselton (2004)"Boiler Operator's Handbook" Fairmont P ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Energy Value Of Coal

The energy value of coal, or fuel content, is the amount of potential energy coal contains that can be converted into Heat of combustion, heat. This value can be calculated and compared with different Coal#Types, grades of coal and other combustible materials, which produce different amounts of heat according to their grade. While chemistry provides ways of calculating the heating value of a certain amount of a substance, there is a difference between this theoretical value and its application to real coal. The grade of a sample of coal does not precisely define its chemical composition, so calculating the coal's actual usefulness as a fuel requires determining its proximate and ultimate analysis (see "Chemical Composition" below). Chemical composition Chemical composition of the coal is defined in terms of its proximate and ultimate (elemental) analyses. The parameters of proximate analysis are moisture, Volatility (chemistry), volatile matter, ash, and fixed carbon. Elemental or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coal Assay

Coal analysis techniques are specific analytical methods designed to measure the particular physical and chemical properties of coals. These methods are used primarily to determine the suitability of coal for coking, power generation or for iron ore smelting in the manufacture of steel. Chemical properties of coal Coal comes in four main types or ranks: lignite or brown coal, bituminous coal or black coal, anthracite and graphite. Each type of coal has a certain set of physical parameters which are mostly controlled by moisture, volatile content (in terms of aliphatic or aromatic hydrocarbons) and carbon content. Moisture Moisture is an important property of coal, as all coals are mined wet. Groundwater and other extraneous moisture is known as ''adventitious moisture'' and is readily evaporated. Moisture held within the coal itself is known as ''inherent moisture'' and is analysed quantitatively. Moisture may occur in four possible forms within coal: * ''Surface moisture'': water ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bituminous Coal

Bituminous coal, or black coal, is a type of coal containing a tar-like substance called bitumen or asphalt. Its coloration can be black or sometimes dark brown; often there are well-defined bands of bright and dull material within the seams. It is typically hard but friable. Its quality is ranked higher than lignite and sub-bituminous coal, but lesser than anthracite. It is the most abundant rank of coal, with deposits found around the world, often in rocks of Carboniferous age. Bituminous coal is formed from sub-bituminous coal that is buried deeply enough to be heated to or higher. Bituminous coal is used primarily for electrical power generation and in the steel industry. Bituminous coal suitable for smelting iron (''coking coal'' or ''metallurgical coal'' ) must be low in sulfur and phosphorus. It commands a higher price than other grades of bituminous coal (thermal coal) used for heating and power generation. Within the coal mining industry, this type of coal is known ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Victoria (Australia)

Victoria is a state in southeastern Australia. It is the second-smallest state with a land area of , the second most populated state (after New South Wales) with a population of over 6.5 million, and the most densely populated state in Australia (28 per km2). Victoria is bordered by New South Wales to the north and South Australia to the west, and is bounded by the Bass Strait to the south (with the exception of a small land border with Tasmania located along Boundary Islet), the Great Australian Bight portion of the Southern Ocean to the southwest, and the Tasman Sea (a marginal sea of the South Pacific Ocean) to the southeast. The state encompasses a range of climates and geographical features from its temperate coastal and central regions to the Victorian Alps in the northeast and the semi-arid north-west. The majority of the Victorian population is concentrated in the central-south area surrounding Port Phillip Bay, and in particular within the metropolit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bacchus Marsh

Bacchus Marsh (Wathawurrung: ''Pullerbopulloke'') is an urban centre and suburban locality in Victoria, Australia located approximately north west of the state capital Melbourne and west of Melton, Victoria, Melton at a near equidistance to the major cities of Melbourne, Ballarat and Geelong. The population of the Bacchus Marsh urban area was 22,223 at June 2018. Bacchus Marsh is the largest urban area in the Local government in Australia, local government area of Shire of Moorabool. Traditionally a Market gardening, market garden area producing a large amount of the region's fruits and vegetables, in recent decades it has transformed into the main commuter town on the Melbourne-Ballarat, Victoria, Ballarat corridor. It was named after the colonial settler Captain William Henry Bacchus, who saw the great value of this locality as it was situated on two rivers — the Lerderderg River, Lerderderg and Werribee River, Werribee. History Aboriginal Bacchus Marsh is on the border ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Maddingley Mine

Maddingley Mine near Bacchus Marsh Railway Station, Victoria, Australia contains a concentration of a particular brown coal (lignite) formation called Leonardite. A relatively high altitude formation, Maddingley brown coal is distinguished as having 60 per cent moisture content and a rich fulvic acid and humic acid content. A declared strategic State mining reserve, the estimated 400 million tonne deposit at Maddingley is the largest of three known deposits of high value Leonardite in the world, the others occurring in Mexico and Germany. History The Maddingley brown coal deposit was surveyed by the 1930s. In the early 1940s brown coal was mined and transported in large quantities by rail from the nearby Rowsley Station, with dedicated trains running between Maddingley and the Australian Paper Manufacturers (APM Siding) at Fairfield, Melbourne. The coal was used to fire boilers at the APM paper mill, with 400 tonnes (440 short tons) of coal per day transferred in two trains p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_Chemist_of_Heidelberg_Wellcome_L0003155.jpg)