|

Binder (material)

A binder or binding agent is any material or substance that holds or draws other materials together to form a cohesive whole mechanically, chemically, by adhesion or cohesion. In a more narrow sense, binders are liquid or dough-like substances that harden by a chemical or physical process and bind fibres, filler powder and other particles added into it. Examples include glue, adhesive and thickening. Examples of mechanical binders are bond stones in masonry and tie beams in timber framing. Classification Binders are loosely classified as organic ( bitums, animal and plant glues, polymers) and inorganic ( lime, cement, gypsum, liquid glass, etc.). These can be either metallic or ceramic as well as polymeric depending on the nature of the main material. For example, in the compound WC-Co (Tungsten Carbide used in cutting tools) Co constitutes the binding agent for the WC particles. Based on their chemical resistance, binders are classified by the field of use: non-hydra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Adhesion

Adhesion is the tendency of dissimilar particles or surfaces to cling to one another ( cohesion refers to the tendency of similar or identical particles/surfaces to cling to one another). The forces that cause adhesion and cohesion can be divided into several types. The intermolecular forces responsible for the function of various kinds of stickers and sticky tape fall into the categories of chemical adhesion, dispersive adhesion, and diffusive adhesion. In addition to the cumulative magnitudes of these intermolecular forces, there are also certain emergent mechanical effects. Surface energy Surface energy is conventionally defined as the work that is required to build an area of a particular surface. Another way to view the surface energy is to relate it to the work required to cleave a bulk sample, creating two surfaces. If the new surfaces are identical, the surface energy γ of each surface is equal to half the work of cleavage, W: γ = (1/2)W11. If the surf ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Lime

Hydraulic lime (HL) is a general term for calcium oxide, a variety of lime also called quicklime, that sets by hydration. This contrasts with calcium hydroxide, also called slaked lime or air lime that is used to make lime mortar, the other common type of lime mortar, which sets by carbonation (re-absorbing carbon dioxide (CO2) from the air). Hydraulic lime provides a faster initial set and higher compressive strength than air lime, and hydraulic lime will set in more extreme conditions, including under water. The terms 'hydraulic lime' and 'hydrated lime' are quite similar and may be confused but are not necessarily the same material. Hydrated lime is any lime which has been slaked whether it sets through hydration, carbonation, or both. Calcium reacts in the lime kiln with the clay minerals to produce silicates that enable some of the lime to set through hydration. Any unreacted calcium is slaked to calcium hydroxide which sets through carbonation. These are sometimes called ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Matrix

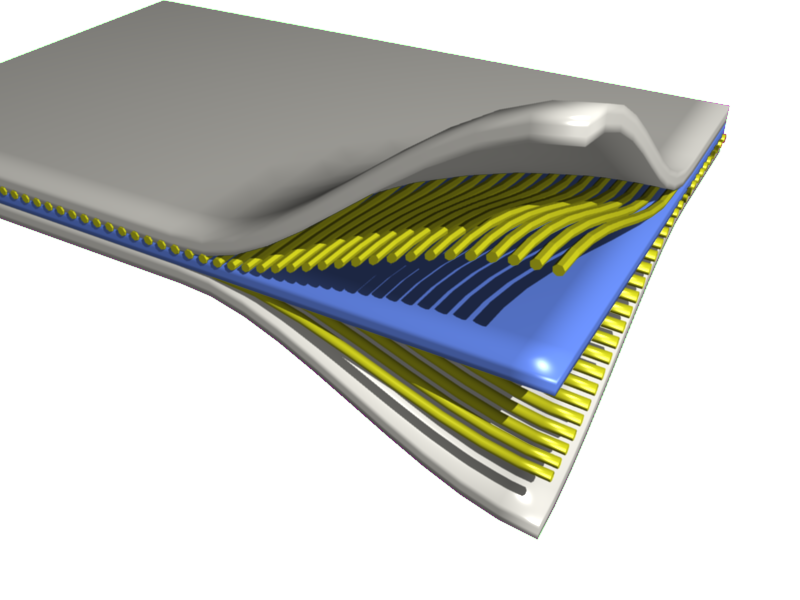

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Typical engineered composite materials include: * Reinforced concrete and masonry * Composite wood such as plywood * Reinforced plastics, such as fibre-reinforced polymer or fiberglass *Ceramic matrix composites ( composite ceramic and metal matrices) * Metal matrix composites *and other advanced composite materials There are various reasons where new material can be favoured. Typical examples include materials which are less expensive, lighter, stronger or more durable when compared with co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Typical Materials, engineered composite materials include: *Reinforced concrete and masonry *Composite wood such as plywood *Reinforced plastics, such as fibre-reinforced polymer or fiberglass *Ceramic matrix composites (composite armor, composite ceramic and metal matrices) *Metal matrix composites *and other Advanced composite materials (engineering), advanced composite materials There are various reasons where new material can be favoured. Typical examples include materials which are less ex ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compression (physics)

In mechanics, compression is the application of balanced inward ("pushing") forces to different points on a material or structure, that is, forces with no net sum or torque directed so as to reduce its size in one or more directions.Ferdinand Pierre Beer, Elwood Russell Johnston, John T. DeWolf (1992), "Mechanics of Materials". (Book) McGraw-Hill Professional, It is contrasted with tension or traction, the application of balanced outward ("pulling") forces; and with shearing forces, directed so as to displace layers of the material parallel to each other. The compressive strength of materials and structures is an important engineering consideration. In uniaxial compression, the forces are directed along one direction only, so that they act towards decreasing the object's length along that direction. The compressive forces may also be applied in multiple directions; for example inwards along the edges of a plate or all over the side surface of a cylinder, so as to reduce ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resin

In polymer chemistry and materials science, resin is a solid or highly viscous substance of plant or synthetic origin that is typically convertible into polymers. Resins are usually mixtures of organic compounds. This article focuses on naturally occurring resins. Plants secrete resins for their protective benefits in response to injury. The resin protects the plant from insects and pathogens. Resins confound a wide range of herbivores, insects, and pathogens, while the volatile phenolic compounds may attract benefactors such as parasitoids or predators of the herbivores that attack the plant. Composition Most plant resins are composed of terpenes. Specific components are alpha-pinene, beta-pinene, delta-3 carene, and sabinene, the monocyclic terpenes limonene and terpinolene, and smaller amounts of the tricyclic sesquiterpenes, longifolene, caryophyllene, and delta-cadinene. Some resins also contain a high proportion of resin acids. Rosins on the other hand ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear Force

In solid mechanics, shearing forces are unaligned forces acting on one part of a body in a specific direction, and another part of the body in the opposite direction. When the forces are collinear (aligned with each other), they are called tension forces and compression forces. William A. Nash defines shear force in terms of planes Plane(s) most often refers to: * Aero- or airplane, a powered, fixed-wing aircraft * Plane (geometry), a flat, 2-dimensional surface Plane or planes may also refer to: Biology * Plane (tree) or ''Platanus'', wetland native plant * ''Planes' ...: "If a plane is passed through a body, a force acting along this plane is called a ''shear force'' or ''shearing force''." Force required to shear steel This section calculates the force required to cut a piece of material with a shearing action. The relevant information is the area of the material being sheared, ie the area across which the shearing action takes place, and the shear strength of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tension (physics)

In physics, tension is described as the pulling force transmitted axially by the means of a string, a rope, chain, or similar object, or by each end of a rod, truss member, or similar three-dimensional object; tension might also be described as the action-reaction pair of forces acting at each end of said elements. Tension could be the opposite of compression. At the atomic level, when atoms or molecules are pulled apart from each other and gain potential energy with a restoring force still existing, the restoring force might create what is also called tension. Each end of a string or rod under such tension could pull on the object it is attached to, in order to restore the string/rod to its relaxed length. Tension (as a transmitted force, as an action-reaction pair of forces, or as a restoring force) is measured in newtons in the International System of Units (or pounds-force in Imperial units). The ends of a string or other object transmitting tension will exert forces on the o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rebar

Rebar (short for reinforcing bar), known when massed as reinforcing steel or reinforcement steel, is a steel bar used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has weak tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface features a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage. The most common type of rebar is carbon steel, typically consisting of hot-rolled round bars with deformation patterns embossed into its surface. Steel and concrete have similar coefficients of thermal expansion, so a concrete structural member reinforced with steel will experience minimal differential stress as the temperature changes. Other readily available types of rebar are manufactured of stainless steel, and composite bars made of glass fiber, car ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tensile Strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials the ultimate tensile strength is close to the yield point, whereas in ductile materials the ultimate tensile strength can be higher. The ultimate tensile strength is usually found by performing a tensile test and recording the engineering stress versus strain. The highest point of the stress–strain curve is the ultimate tensile strength and has units of stress. The equivalent point for the case of compression, instead of tension, is called the compressive strength. Tensile strengths are rarely of any consequence in the design of ductile members, but they are important with brittle members. They are tabulated for common materials such as alloys, composite materials, ceramics, plastics, and wood. Definition The ultimate tensile ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compressive Strength

In mechanics, compressive strength or compression strength is the capacity of a material or structure to withstand loads tending to reduce size (as opposed to tensile strength which withstands loads tending to elongate). In other words, compressive strength resists compression (being pushed together), whereas tensile strength resists tension (being pulled apart). In the study of strength of materials, tensile strength, compressive strength, and shear strength can be analyzed independently. Some materials fracture at their compressive strength limit; others deform irreversibly, so a given amount of deformation may be considered as the limit for compressive load. Compressive strength is a key value for design of structures. Compressive strength is often measured on a universal testing machine. Measurements of compressive strength are affected by the specific test method and conditions of measurement. Compressive strengths are usually reported in relationship to a specific ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Calcium Silicate

Calcium silicate is the chemical compound Ca2SiO4, also known as calcium orthosilicate and is sometimes formulated as 2CaO·SiO2. It is also referred to by the shortened trade name Cal-Sil or Calsil. It occurs naturally as the mineral larnite. Properties Calcium silicate is a white free-flowing powder. It can be derived from naturally occurring limestone and diatomaceous earth, a siliceous sedimentary rock. It is one of a group of compounds that can be produced by reacting calcium oxide and silica in various ratios e.g. 3CaO·SiO2, alite (Ca3SiO5); 2CaO·SiO2, (Ca2SiO4); 3CaO·2SiO2, (Ca3SiO7); and CaO·SiO2, wollastonite (CaSiO3). It has a low bulk density and high physical water absorption. Use Calcium silicate is used as an anticaking agent in food preparation, including table salt and as an [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)