|

Bending (metalworking)

Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal.Manufacturing Processes Reference Guide, Industrial Press Inc., 1994. Commonly used equipment include box and pan brakes, brake presses, and other specialized machine presses. Typical products that are made like this are boxes such as electrical enclosures and rectangular ductwork. Process In press brake forming, a work piece is positioned over the die block and the die block presses the sheet to form a shape. Usually bending has to overcome both tensile stresses and compressive stresses. When bending is done, the residual stresses cause the material to ' towards its original position, so the sheet must be over-bent to achieve the proper bend angle. The amount of spring back is dependent on the material, and the type of forming. When sheet metal is bent, it stretches in length. The ''bend deduction'' is the amount t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tension (physics)

In physics, tension is described as the pulling force transmitted axially by the means of a string, a rope, chain, or similar object, or by each end of a rod, truss member, or similar three-dimensional object; tension might also be described as the action-reaction pair of forces acting at each end of said elements. Tension could be the opposite of compression. At the atomic level, when atoms or molecules are pulled apart from each other and gain potential energy with a restoring force still existing, the restoring force might create what is also called tension. Each end of a string or rod under such tension could pull on the object it is attached to, in order to restore the string/rod to its relaxed length. Tension (as a transmitted force, as an action-reaction pair of forces, or as a restoring force) is measured in newtons in the International System of Units (or pounds-force in Imperial units). The ends of a string or other object transmitting tension will exert forces on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hemming And Seaming

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials.. Hems are commonly used to reinforce an edge, hide burrs and rough edges, and improve appearance. Seams are commonly used in the food industry on canned goods, on amusement park cars, in metal roofing (with a roof seamer), and in the automotive industry. Process The process for both hemming and seaming are the same, except that the tonnage (amount of force exerted) requirement is greater for seaming. The process starts by bending the edge to an acute angle. A flattening die is then used to flatten the hem. Types There are two types of hemmed edges: ''closed hems'' and ''open hems''. Closed hems are completely flush while open hems have an air pocket in the bend. The major difference is that the tonnage required for a closed hem is much greater than ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bending Machine (manufacturing)

A bending machine is a forming machine tool (DIN 8586). Its purpose is to assemble a bend on a workpiece. A bend is manufactured by using a bending tool during a linear or rotating move. The detailed classification can be done with the help of the kinematics.M. Weck, p. 112 CNC bending CNC bending machines are developed for high flexibility and low setup times. Those machines are able to bend single pieces as well as small batches with the same precision and efficiency as series-produced parts in an economical way. Universal bending machines – modular construction Universal bending machines consists of a basic machine that can be adjusted with little effort and used for a variety of bends. A simple plug-in system supports quick and easy exchange of tools. The basic machine consists of a CNC-operated side stop, a work bench, and software for programming and operating. Its modular construction offers an affordable entry into the bending technology, because after an initial ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brake (sheet Metal Bending)

A brake is a metalworking machine that allows the bending of sheet metal. A cornice brake only allows for simple bends and creases, while a box-and-pan brake also allows one to form box and pan shapes. It is also known as a bending machine or bending brake or in Britain as a sheet metal folder or just a folder. Description The brake consists of a flat surface onto which the material is placed, and a clamping bar which will come down and hold the material firmly during the bend. This clamping action may be manual, automatic or operated using a foot pedal. The front, gate-like, plate of the machine is hinged and may be lifted, forcing the material extended over a straight edge to bend to follow the plate. The bends can be to any angle up to a practical limit of about 120 degrees, somewhat more in the case of a bar folder. If the area to be bent is narrow enough, a sharper bend (e.g., for a hem) can be made by inserting the bend under the clamping bar and lowering it. Box-and-p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Press Brake

A press brake is a machine used for bending sheet metal and metal plate, most commonly sheet metal. It forms predetermined bends by clamping the workpiece between a matching top tool and bottom die.Parker, Dana T. ''Building Victory: Aircraft Manufacturing in the Los Angeles Area in World War II,'' p. 29, 83, Cypress, CA, 2013. ISBN 978-0-9897906- 0-4. Typically, two C-frames form the sides of the press brake, connected to a table at the bottom and on a movable beam at the top. The bottom tool is mounted on the table, with the top tool mounted on the upper beam. Types A brake can be described by basic parameters, such as the force or tonnage and the working length. Additional parameters include the stroke length, the distance between the frame uprights or side housings, distance to the back gauge, and work height. The upper beam usually operates at a speed ranging from 1 to 15 mm/s. There are several types of press brakes including nut-stop hydraulic, synchro hydraulic, ele ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tube Bending

Tube bending is any metal forming processes used to permanently form pipes or tubing. Tube bending may be form-bound or use freeform-bending procedures, and it may use heat supported or cold forming procedures. Form bound bending procedures like “press bending” or “rotary draw bending” are used to form the work piece into the shape of a die. Straight tube stock can be formed using a bending machine to create a variety of single or multiple bends and to shape the piece into the desired form. These processes can be used to form complex shapes out of different types of ductile metal tubing. Freeform-bending processes, like three-roll-pushbending, shape the workpiece kinematically, thus the bending contour is not dependent on the tool geometry. Generally, round stock is used in tube bending. However, square and rectangular tubes and pipes may also be bent to meet job specifications. Other factors involved in the bending process are the wall thickness, tooling and lubricants ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bending

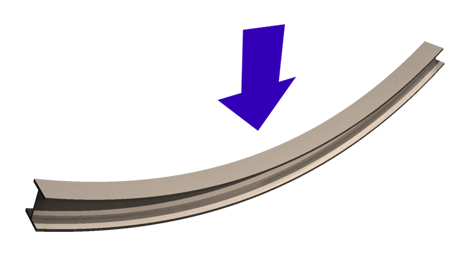

In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically 1/10 or less, of the other two.Boresi, A. P. and Schmidt, R. J. and Sidebottom, O. M., 1993, Advanced mechanics of materials, John Wiley and Sons, New York. When the length is considerably longer than the width and the thickness, the element is called a beam. For example, a closet rod sagging under the weight of clothes on clothes hangers is an example of a beam experiencing bending. On the other hand, a shell is a structure of any geometric form where the length and the width are of the same order of magnitude but the thickness of the structure (known as the 'wall') is considerably smaller. A large diameter, but thin-walled, short tube supported at its ends an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

K-factor (sheet Metal)

Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal.Manufacturing Processes Reference Guide, Industrial Press Inc., 1994. Commonly used equipment include box and pan brakes, brake presses, and other specialized machine presses. Typical products that are made like this are boxes such as electrical enclosures and rectangular ductwork. Process In press brake forming, a work piece is positioned over the die block and the die block presses the sheet to form a shape. Usually bending has to overcome both tensile stresses and compressive stresses. When bending is done, the residual stresses cause the material to ' towards its original position, so the sheet must be over-bent to achieve the proper bend angle. The amount of spring back is dependent on the material, and the type of forming. When sheet metal is bent, it stretches in length. The ''bend deduction'' is the amount the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bend Deduction

Bend may refer to: Materials * Bend, a curvature in a pipe, tube, or pipeline (see Bend radius) * Bend knot, a knot used to tie two ropes together; see List of bend knots *Bending, the deformation of an object due to an applied load Music Musical techniques * Bend (guitar), a guitar technique * Bending, for blues harp (harmonica) Albums and songs * ''Bend'' (8stops7 album), 2006 * ''Bend'' (The Origin album), 1992 * "Bend" (song), a 2015 song by Chet Faker People * Lin Bend (1922–1978), Canadian ice hockey centre * Robert Bend (1914–1999), Manitoba politician Places * Bend, British Columbia, a railway point in Canada * Bend, California * Bend, Missouri * Bend, Oregon * Bend, South Dakota * Bend, Texas Other uses * Bend (heraldry), a diagonal band used as a heraldic charge * Bend, a meander in a river * Decompression sickness, commonly known as "the bends" * Curl (association football), a playing technique also called "bend" See also * * * Bends (other) * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bend Allowance

Bend may refer to: Materials * Bend, a curvature in a pipe, tube, or pipeline (see Bend radius) * Bend knot, a knot used to tie two ropes together; see List of bend knots *Bending, the deformation of an object due to an applied load Music Musical techniques * Bend (guitar), a guitar technique * Bending, for blues harp (harmonica) Albums and songs * ''Bend'' (8stops7 album), 2006 * ''Bend'' (The Origin album), 1992 * "Bend" (song), a 2015 song by Chet Faker People * Lin Bend (1922–1978), Canadian ice hockey centre * Robert Bend (1914–1999), Manitoba politician Places * Bend, British Columbia, a railway point in Canada * Bend, California * Bend, Missouri * Bend, Oregon * Bend, South Dakota * Bend, Texas Other uses * Bend (heraldry), a diagonal band used as a heraldic charge * Bend, a meander in a river * Decompression sickness, commonly known as "the bends" * Curl (association football), a playing technique also called "bend" See also * * * Bends (other) * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Design

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software are helpful in protecting products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer aided design and drafting (CADD) are also used. Its use in designing electronic systems is known as '' electronic design automation'' (''EDA''). In mechanical design it is known as ''mechanical design automation'' (''MDA''), which includes the process of creating a technical drawing with the use of computer software. CAD software for mechanical design uses either vector-based graphic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |