|

Blowdown Stack

A blowdown stack is an elevated vent or vertical stack that is used to vent the pressure of components of a chemical, refinery or other plant if there is a process problem or emergency. A blowdown stack can be used to complement a flare stack or as an alternative. The purpose is to prevent 'loss of containment' of volatile liquids and gases. Blowdown from several systems may be combined in a blowdown header prior to the stack. A knock-out pot may be provided at the base of the stack to remove any liquids. Blowdown stacks may either be ignited (like a flare) or un-ignited (a ‘cold’ vent). The height of the blowdown stack must be tall enough to ensure the safe dispersal of vapour. Blowdown Blowdown is the controlled removal, safe flow and disposal of vapour from a pressure vessel. Blowdown, or depressurisation, removes hazardous inventory from a vessel, reduces the pressure in the vessel and thereby reduces the stresses in the vessel walls. Blowdown is used prior to draining ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Refinery

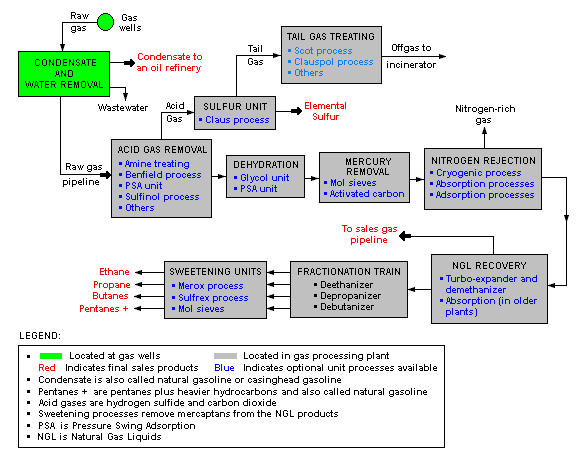

A refinery is a production facility composed of a group of chemical engineering unit processes and unit operations refining certain materials or converting raw material into products of value. Types of refineries Different types of refineries are as follows: * oil refinery, Petroleum oil refinery, which converts crude oil into Octane rating, high-octane motor spirit (gasoline/petrol), diesel oil, liquefied petroleum gases (LPG), kerosene, heating fuel oils, hexane, lubricating oils, bitumen and petroleum coke * Cooking oil#Refinement, Edible oil refinery which converts cooking oil into a product that is uniform in taste, smell and appearance, and stability *Natural gas processing plant, which purifies and converts raw natural gas into residential, commercial and industrial fuel gas, and also recovers natural gas liquids (NGL) such as ethane, propane, butanes and pentanes * Sugar refinery, which converts sugar cane and sugar beets into crystallized sugar and sugar syrups * Salt re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flare Stack

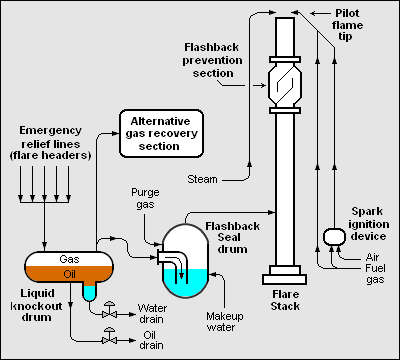

A gas flare, alternatively known as a flare stack, flare boom, ground flare, or flare pit is a gas combustion device used in places such as petroleum refineries, chemical plants and natural gas processing plants, oil or gas extraction sites having oil wells, gas wells, offshore oil and gas rigs and landfills. In industrial plants, flare stacks are primarily used for burning off flammable gas released by safety valves during unplanned over-pressuring of plant equipment. (See Chapter 11, ''Flare Stack Plume Rise''). During plant or partial plant startups and shutdowns, they are also often used for the planned combustion of gases over relatively short periods. At oil and gas extraction sites, gas flares are similarly used for a variety of startup, maintenance, testing, safety, and emergency purposes. In a practice known as production flaring, they may also be used to dispose of large amounts of unwanted associated petroleum gas, possibly throughout the life of an oil well. 5 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vapor–liquid Separator

In chemical engineering, a vapor–liquid separator is a device used to separate a vapor–liquid mixture into its constituent phases. It can be a vertical or horizontal vessel, and can act as a 2-phase or 3-phase separator. A vapor–liquid separator may also be referred to as a ''flash drum'', ''breakpot'', ''knock-out drum'' or ''knock-out pot'', ''compressor suction drum, suction scrubber'' or ''compressor inlet drum,'' or ''vent scrubber.'' When used to remove suspended water droplets from streams of air, it is often called a demister. Method of operation In vapor-liquid separators gravity is utilized to cause the denser fluid (liquid) to settle to the bottom of the vessel where it is withdrawn, less dense fluid (vapor) is withdrawn from the top of the vessel. In low gravity environments such as a space station, a common liquid separator will not function because gravity is not usable as a separation mechanism. In this case, centrifugal force needs to be utilised in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vapor

In physics, a vapor (American English) or vapour (British English and Canadian English; see spelling differences) is a substance in the gas phase at a temperature lower than its critical temperature,R. H. Petrucci, W. S. Harwood, and F. G. Herring, ''General Chemistry'', Prentice-Hall, 8th ed. 2002, p. 483–86. which means that the vapor can be condensed to a liquid by increasing the pressure on it without reducing the temperature. A vapor is different from an aerosol. An aerosol is a suspension of tiny particles of liquid, solid, or both within a gas. For example, water has a critical temperature of , which is the highest temperature at which liquid water can exist. In the atmosphere at ordinary temperatures gaseous water (known as water vapor) will condense into a liquid if its partial pressure is increased sufficiently. A vapor may co-exist with a liquid (or a solid). When this is true, the two phases will be in equilibrium, and the gas-partial pressure will be equal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Construction methods and materials may be chosen to suit the pressure application, and will depend on the size of the vessel, the contents, working pressure, mass constraints, and the number of items required. Pressure vessels can be dangerous, and fatal accidents have occurred in the history of their development and operation. Consequently, pressure vessel design, manufacture, and operation are regulated by engineering authorities backed by legislation. For these reasons, the definition of a pressure vessel varies from country to country. Design involves parameters such as maximum safe operating pressure and temperature, safety factor, corrosion allowance and minimum design temperature (for brittle fracture). Construction is tested using nondestructive testing, such as ultrasonic testing, radiography, and pressure tests. Hydrostatic pressure tests ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Orifice Plate

An orifice plate is a device used for measuring flow rate, for reducing pressure or for restricting flow (in the latter two cases it is often called a '). Description An orifice plate is a thin plate with a hole in it, which is usually placed in a pipe. When a fluid (whether liquid or gaseous) passes through the orifice, its pressure builds up slightly upstream of the orifice but as the fluid is forced to converge to pass through the hole, the velocity increases and the fluid pressure decreases. A little downstream of the orifice the flow reaches its point of maximum convergence, the ''vena contracta'' (see drawing to the right) where the velocity reaches its maximum and the pressure reaches its minimum. Beyond that, the flow expands, the velocity falls and the pressure increases. By measuring the difference in fluid pressure across tappings upstream and downstream of the plate, the flow rate can be obtained from Bernoulli's equation using coefficients established from extensive r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Joule–Thomson Effect

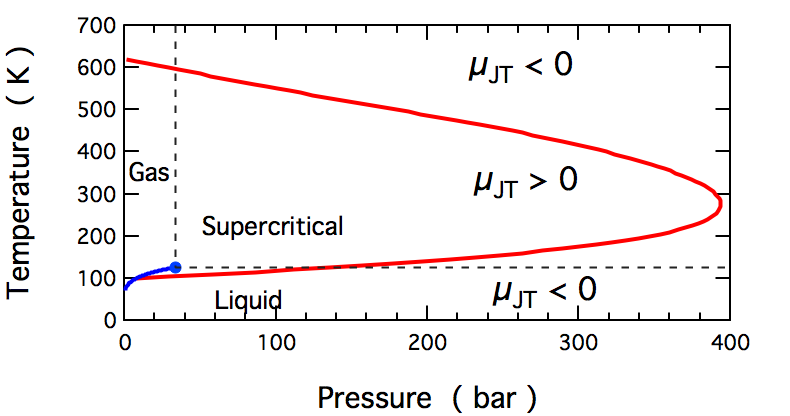

In thermodynamics, the Joule–Thomson effect (also known as the Joule–Kelvin effect or Kelvin–Joule effect) describes the temperature change of a ''real'' gas or liquid (as differentiated from an ideal gas) when it is forced through a valve or porous plug while keeping it insulated so that no heat is exchanged with the environment. This procedure is called a ''throttling process'' or ''Joule–Thomson process''. At room temperature, all gases except hydrogen, helium, and neon cool upon expansion by the Joule–Thomson process when being throttled through an orifice; these three gases experience the same effect but only at lower temperatures. Most liquids such as hydraulic oils will be warmed by the Joule–Thomson throttling process. The gas-cooling throttling process is commonly exploited in refrigeration processes such as liquefiers in air separation industrial process. In hydraulics, the warming effect from Joule–Thomson throttling can be used to find internall ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fracture

Fracture is the separation of an object or material into two or more pieces under the action of stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid. If a displacement develops perpendicular to the surface, it is called a normal tensile crack or simply a crack; if a displacement develops tangentially, it is called a shear crack, slip band or dislocation. Fracture#Brittle, Brittle fractures occur with no apparent deformation before fracture. Fracture#Ductile, Ductile fractures occur after visible deformation. Fracture strength, or breaking strength, is the stress when a specimen fails or fractures. The detailed understanding of how a fracture occurs and develops in materials is the object of fracture mechanics. Strength Fracture strength, also known as breaking strength, is the stress at which a specimen Structural integrity and failure, fails via fracture. This is usually determined for a gi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrocarbon

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons are examples of group 14 hydrides. Hydrocarbons are generally colourless and hydrophobic, and their odors are usually weak or exemplified by the odors of gasoline and lighter fluid. They occur in a diverse range of molecular structures and phases: they can be gases (such as methane and propane), liquids (such as hexane and benzene), low melting solids (such as paraffin wax and naphthalene) or polymers (such as polyethylene and polystyrene). In the fossil fuel industries, ''hydrocarbon'' refers to the naturally occurring petroleum, natural gas and coal, and to their hydrocarbon derivatives and purified forms. Combustion of hydrocarbons is the main source of the world's energy. Petroleum is the dominant raw-material source for organic commodity chemicals such as solvents and polymers. Most anthropogenic (human-generated) emissions of greenhouse gases are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Raffinate

In chemical separation terminology, the raffinate (from French ''raffiner'', to refine) is a product which has had a component or components removed. The product having the removed materials is referred to as the extract. For example, in solvent extraction, the raffinate is the liquid stream which remains after solutes from the original liquid are removed through contact with an immiscible liquid. In metallurgy, raffinating refers to a process in which impurities are removed from liquid material. In pressure swing adsorption the raffinate refers to the gas which is not adsorbed during the high pressure stage. The species which is desorbed from the adsorbent at low pressure may be called the "extract" product. Types Raffinate-1 or C4R1 In naphtha cracking process, C4R1 refers to C4 residual obtained after separation of 1,3-butadiene from C4 raffinate stream and which, mainly consists of isobutylene 40~50 wt% and ''cis''- or ''trans''-2-butene 30~35 wt%. Normally C4R1 is a side pro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Texas City Refinery Explosion

The Texas City Refinery explosion occurred on March 23, 2005, when a vapor cloud of natural gas and petroleum ignited and violently exploded at the isomerization (ISOM) process unit at the BP Texas City refinery in Texas City, Texas, killing 15 workers, injuring 180 others and severely damaging the refinery. The Texas City Refinery was the second-largest oil refinery in the state, and the third-largest in the United States with an input capacity of per day as of January 1, 2000. BP acquired the Texas City refinery as part of its merger with Amoco in 1999. BP's own accident investigation report stated that the direct cause of the accident was " ..eavier–than-air hydrocarbon vapors combusting after coming into contact with an ignition source, probably a running vehicle engine. The hydrocarbons originated from liquid overflow from the F-20 blowdown stack following the operation of the raffinate splitter overpressure protection system caused by overfilling and overheating of t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Flare

A gas flare, alternatively known as a flare stack, flare boom, ground flare, or flare pit is a gas combustion device used in places such as petroleum refineries, chemical plants and natural gas processing plants, oil or gas extraction sites having oil wells, gas wells, offshore oil and gas rigs and landfills. In industrial plants, flare stacks are primarily used for burning off flammable gas released by safety valves during unplanned over-pressuring of plant equipment. (See Chapter 11, ''Flare Stack Plume Rise''). During plant or partial plant startups and shutdowns, they are also often used for the planned combustion of gases over relatively short periods. At oil and gas extraction sites, gas flares are similarly used for a variety of startup, maintenance, testing, safety, and emergency purposes. In a practice known as production flaring, they may also be used to dispose of large amounts of unwanted associated petroleum gas, possibly throughout the life of an oil well. 5 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |