|

Arbor (tool)

A mandrel, mandril, or arbor is a gently tapered cylinder against which material can be forged or shaped (e.g., a ring mandrel - also called a triblet - used by jewelers to increase the diameter of a wedding ring), or a flanged or tapered or threaded bar that grips a workpiece to be machined in a lathe. A flanged mandrel is a parallel bar of a specific diameter with an integral flange towards one end, and threaded at the opposite end. Work is gripped between the flange and a nut on the thread. A tapered mandrel (often called a plain mandrel) has a taper of approximately 0.005 inches per foot and is designed to hold work by being driven into an accurate hole on the work, gripping the work by friction. A threaded mandrel may have a male or female thread, and work which has an identical thread is screwed onto the mandrel. On a lathe, mandrels are commonly mounted between centres and driven by a lathe dog (typically the flanged or tapered mandrels), but may also be gripped in a c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

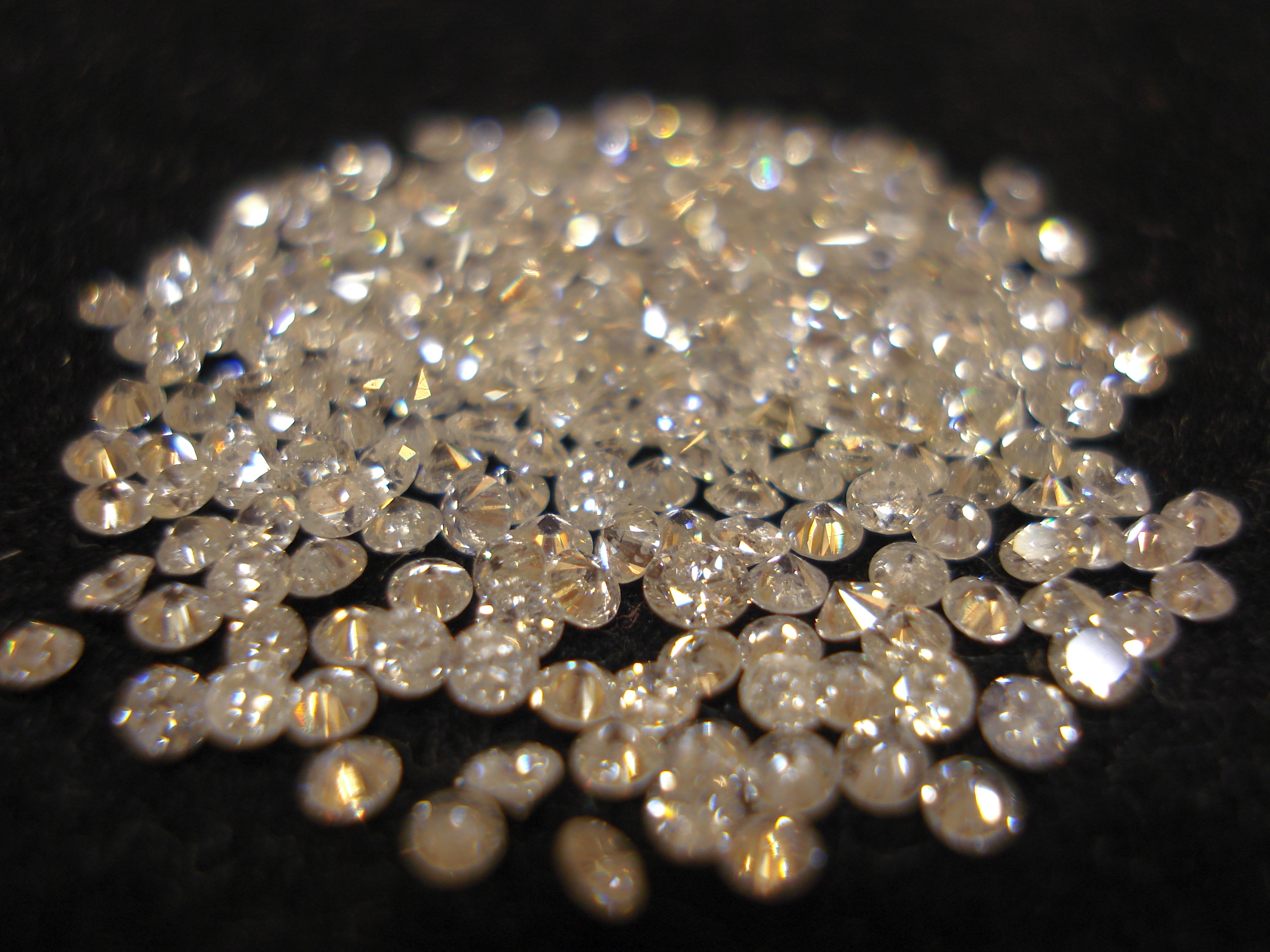

Jewellery Mandrels (2)

Jewellery ( UK) or jewelry (U.S.) consists of decorative items worn for personal adornment, such as brooches, rings, necklaces, earrings, pendants, bracelets, and cufflinks. Jewellery may be attached to the body or the clothes. From a western perspective, the term is restricted to durable ornaments, excluding flowers for example. For many centuries metal such as gold often combined with gemstones, has been the normal material for jewellery, but other materials such as glass, shells and other plant materials may be used. Jewellery is one of the oldest types of archaeological artefact – with 100,000-year-old beads made from ''Nassarius'' shells thought to be the oldest known jewellery.Study reveals 'oldest jewellery' , '' |

Lathes

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a chuck or collet ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clamps (tool)

Clamp may refer to: Tools and devices *Brick clamp, an early method of baking bricks *Clamp (tool), a device or tool used to hold objects in a fixed relative position (many types listed) **C-clamp **C-clamp (stagecraft) **Riser clamp, a device used to support vertical piping *Nipple clamp, a sex toy *Storage clamp, an agricultural root crop storage *Wheel clamp, a device used with road vehicles to prevent theft or enforce parking restrictions Biology and medicine * CLAMP (Climate leaf analysis multivariate program), a method for characterizing past climates * Clamp (zoology), an attachment structure found in some parasitic flatworms * Clamp connection, a structure formed by hyphal cells of certain fungi * DNA clamp, a ring-like structure associated with DNA replication and other phenomena * Glucose clamp technique, a method for quantifying insulin secretion and resistance * Patch clamp, a technique used to hold a natural cell membrane or artificial lipid bilayer Electronics and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gear

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic principle behind the operation of gears is analogous to the basic principle of levers. A gear may also be known informally as a cog. Geared devices can change the speed, torque, and direction of a power source. Gears of different sizes produce a change in torque, creating a mechanical advantage, through their ''gear ratio'', and thus may be considered a simple machine. The rotational speeds, and the torques, of two meshing gears differ in proportion to their diameters. The teeth on the two meshing gears all have the same shape. Two or more meshing gears, working in a sequence, are called a gear train or a '' transmission''. The gears in a transmission are analogous to the wheels in a crossed, belt pulley system. An advantage of gears is tha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Leadscrew

A leadscrew (or lead screw), also known as a power screw or translation screw,Bhandari, p. 202. is a screw (simple machine), screw used as a linkage (mechanical), linkage in a machine, to translate Rotation, turning motion into linear motion. Because of the large area of sliding contact between their gender of connectors and fasteners, male and female members, screw threads have larger frictional energy losses compared to other linkages. They are not typically used to carry high power, but more for intermittent use in low power actuator and positioner mechanisms. Leadscrews are commonly used in linear actuators, machine slides (such as in machine tools), vise (tool), vises, mechanical press, presses, and jack (device), jacks.Shigley, p. 400. Leadscrews are a common component in electric linear actuators. Leadscrews are manufactured in the same way as other thread forms (they may be threading (manufacturing), rolled, cut, or ground). A lead screw is sometimes used with a spli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw Thread

A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a ''straight'' thread and the latter called a ''tapered'' thread. A screw thread is the essential feature of the screw as a simple machine and also as a threaded fastener. The mechanical advantage of a screw thread depends on its ''lead'', which is the linear distance the screw travels in one revolution. In most applications, the lead of a screw thread is chosen so that friction is sufficient to prevent linear motion being converted to rotary, that is so the screw does not slip even when linear force is applied, as long as no external rotational force is present. This characteristic is essential to the vast majority of its uses. The tightening of a fastener's screw thread is comparable to driving a wedge into a gap until it sticks fast thro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bearing (mechanical)

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may ''prevent'' a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts. Rotary bearings hold rotating components such as shafts or axles within mechanical systems, and transfer axial and radial loads from the source of the load to the structure supporting it. The simplest form of bearing, the ''plain bearing'', consists of a shaft rotating in a hole. Lubrication is used to reduce friction. In the ''ball bearing'' and ''roller bearing'', to reduce sliding ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal Spinning

Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Spinning can be performed by hand or by a CNC lathe. The metal spinning trade is one that dates back to antiquity and was a skill used in the Ancient Egyptian era. This is when metal spinning was limited to soft metals spun by human power on primitive lathes. The technique gave significant advances to hydro and steam power in Europe and North America in the 19th century and by the early 20th century the electric motor provided the necessary power and high-speed turning capability. With this advancement, metal spinning craftsmen were now able to spin higher quality pieces made out of brass, copper, aluminum and even stainless and cold-rolled steel. Metal spinning does not involve removal of material, as in conventional wood or metal turning, but forming (moulding) of shee ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hole Saw

A hole saw (also styled holesaw), also known as a hole cutter, is a saw blade of annular (ring) shape, whose annular kerf creates a hole in the workpiece without having to cut up the core material. It is used in a drill. Hole saws typically have a pilot drill bit (arbor) at their center to keep the saw teeth from walking. The fact that a hole saw creates the hole without needing to cut up the core often makes it preferable to twist drills or spade drills for relatively large holes (especially those larger than ). The same hole can be made faster and using less power. The depth to which a hole saw can cut is limited by the depth of its cup-like shape. Most hole saws have a fairly short aspect ratio of diameter to depth, and they are used to cut through relatively thin workpieces. However, longer aspect ratios are available for applications that warrant them. Cutting with a hole saw is analogous to some machining operations, called ''trepanning'' in the trade, that swing a cut ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Typical engineered composite materials include: *Reinforced concrete and masonry *Composite wood such as plywood *Reinforced plastics, such as fibre-reinforced polymer or fiberglass *Ceramic matrix composites ( composite ceramic and metal matrices) *Metal matrix composites *and other advanced composite materials There are various reasons where new material can be favoured. Typical examples include materials which are less expensive, lighter, stronger or more durable when compared with commo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Filament Winding

Filament winding is a fabrication technique mainly used for manufacturing open (cylinders) or closed end structures (pressure vessels or tanks). This process involves winding filaments under tension over a rotating mandrel. The mandrel rotates around the spindle (Axis 1 or X: Spindle) while a delivery eye on a carriage (Axis 2 or Y: Horizontal) traverses horizontally in line with the axis of the rotating mandrel, laying down fibers in the desired pattern or angle to the rotational axis. The most common filaments are glass or carbon and are impregnated with resin by passing through a bath as they are wound onto the mandrel. Once the mandrel is completely covered to the desired thickness, the resin is cured. Depending on the resin system and its cure characteristics, often the mandrel is autoclaved or heated in an oven or rotated under radiant heaters until the part is cured. Once the resin has cured, the mandrel is removed or extracted, leaving the hollow final product. For some prod ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |