|

WorkXPlore 3D

PartXplore is a proprietary computer aided design (CAD) file viewer developed by Sescoi for reading, analyzing, and sharing 3D and 2D CAD files without requiring the original CAD application. It was introduced in 2008 and is supported from local Vero offices. The software is available as a viewer and an evaluation version. Functionality PartXplore serves as a collaborative viewer for 2D and 3D CAD files, allowing users to measure 3D parts and analyze various properties such as undercut areas, plane surfaces, thickness, volumes, surfaces, and weight. The software also provides dynamic cross-sectional visualization. PartXplore enables users to add dimensional and geometric measurements, annotations, and labels directly to the 3D model. Additionally, the software facilitates the sharing of 3D parts and assembly files through a standalone application that can be transmitted as an executable file. The recipient can then access and work on the 3D model received.TCT magazine, âPartX ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vero Software

Vero Software is a company based in Cheltenham, England, that specialises in CAD CAM (Computer Aided Design and Manufacturing). History Vero was founded in Northern Italy in October 1988 by Don Babbs and Ezio Galardo when they left Olivetti. In the mid 1990s, its VISI-CAD and VISI-CAM products were the first to use the PC implementation of the Parasolid kernel. The company was incorporated in 1997 under the name ''Deepcredit Limited'', and then renamed as ''VI Group Plc'' in 1998 prior to its listing on the London Stock Market. In October 2007, the company was renamed to Vero Software. On 11 August 2008, Vero Software Plc and its UK subsidiaries Vero UK Limited and Camtek Limited moved to a combined facility in Cheltenham, Gloucestershire from its previous location in Stroud. In 2010 and 2014 Vero Software was awarded ' The Queens Award for Enterprise'. Vero Software develops and distributes software for aiding the design and manufacturing processes, providing solutions for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

IGES

The Initial Graphics Exchange Specification (IGES) is a vendor-neutral file format that allows the digital exchange of information among computer-aided design (CAD) systems. It's an ASCII-based textual format. The official title of IGES is ''Digital Representation for Communication of Product Definition Data'', first published in March, 1980 by the U.S. National Bureau of Standards as NBSIR 80-1978. Many documents (like early versions of the Defense Standards MIL-PRF-28000 and MIL-STD-1840) referred to it as ASME Y14.26M, the designation of the ANSI committee that approved IGES Version 1.0. Using IGES, a CAD user can exchange product data models in the form of circuit diagrams, wireframe, freeform surface or solid modeling representations. Applications supported by IGES include traditional engineering drawings, models for analysis, and other manufacturing functions. History IGES was an initiative of the United States Air Force (USAF) Integrated Computer Aided Manufacturing (IC ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

WorkNC

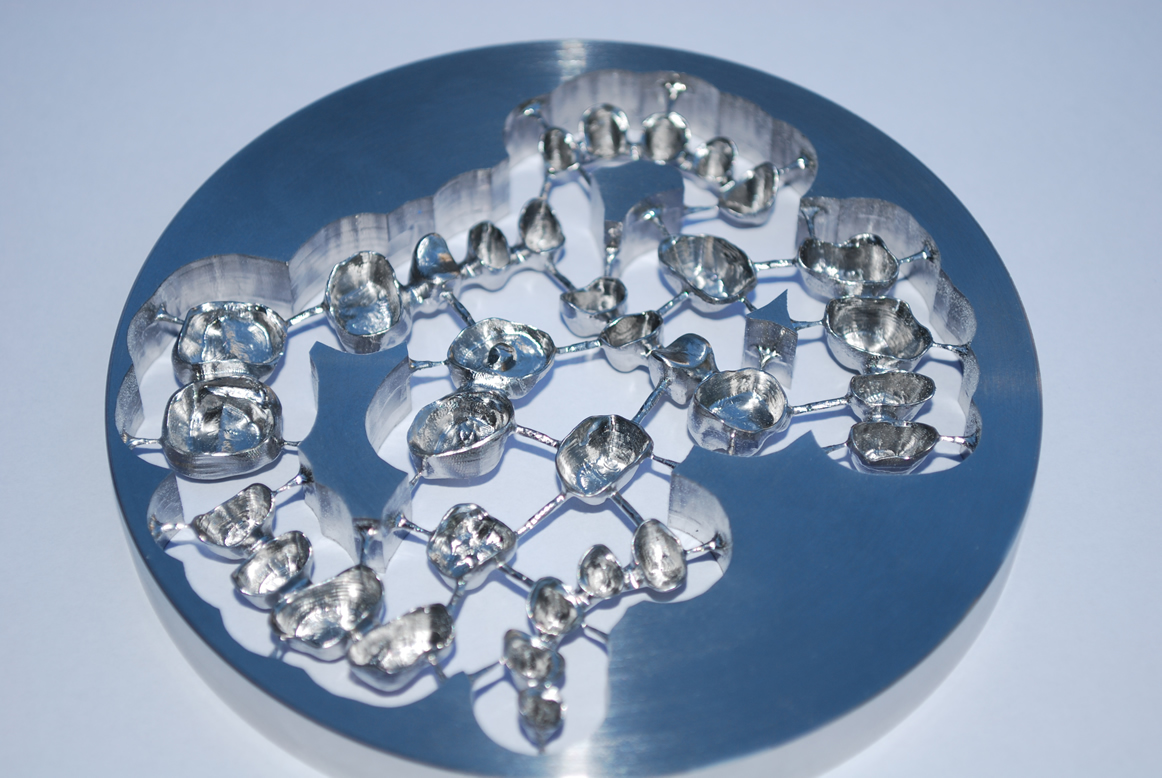

WorkNC is a Computer aided manufacturing (CAM) software developed by Sescoi for multi-axis machining. History The first version of WorkNC CAM software was released by Sescoi, in 1988. The driving forces behind the product were Bruno Marko, president of Sescoi, and Gerard Billard, R&D Innovation Manager. Salomon Group was the first customer to use WorkNC in 1988 in order to manufacture ski boots and other sports equipment. In 2002 the company released WorkNC-CAD, followed by WorkNC 5-axis in 2003 and WorkNC G3 in 2007. In 2008 Sescoi launched WorkXPlore 3D, a collaborative viewer for 3D CAD files that didn't require the original CAD application. In 2009 the company launched WorkNC Dental, a CAD/CAM software for machining of prosthetic appliances, implants or dental structures, as well as WorkNC Wire EDM, a software for Wire EDM. In 2010 Sescoi launched WorkNC-CAD Hybrid Modeling, a 3D CAD software for 3D model design, reparation, machining preparation, and surface desig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

G-code

G-code (also RS-274) is the most widely used computer numerical control (CNC) programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, and has many variants. G-code instructions are provided to a machine controller (industrial computer) that tells the motors where to move, how fast to move, and what path to follow. The two most common situations are that, within a machine tool such as a lathe or mill, a cutting tool is moved according to these instructions through a toolpath cutting away material to leave only the finished workpiece and/or an unfinished workpiece is precisely positioned in any of up to nine axes around the three dimensions relative to a toolpath and, either or both can move relative to each other. The same concept also extends to noncutting tools such as forming or burnishing tools, photoplotting, additive methods such as 3D printing, and measuring instruments. Implementations The first implementation of a nu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Numerical Control

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

UNISURF

UNISURF was a pioneering surface CAD/CAM system, designed to assist with car body design and tooling. It was developed by French engineer Pierre BĂ©zier for Renault Groupe Renault ( , , , also known as the Renault Group in English; legally Renault S.A.) is a French multinational automobile manufacturer established in 1899. The company produces a range of cars and vans, and in the past has manufactured ... in 1968, and entered full use at the company in 1975. By 1999, around 1,500 Renault employees made use of UNISURF for car design and manufacture. References External links * Computer-aided design software Renault {{compu-graphics-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solid Edge

Solid Edge is a 3D CAD, parametric feature and synchronous technology solid modeling software. It runs on Microsoft Windows and provides solid modeling, assembly modelling and 2D orthographic view functionality for mechanical designers. Through third party applications it has links to many other Product Lifecycle Management (PLM) technologies. Originally developed and released by Intergraph in 1996 using the ACIS geometric modeling kernel, it changed to using the Parasolid kernel when it was purchased and further developed by UGS Corp in 1998. In 2007, UGS was acquired by the Automation & Drives Division of Siemens AG. UGS company was renamed Siemens Digital Industries Software on October 1, 2007. Since September 2006, Siemens has also offered a free 2D version called Solid Edge 2D Drafting. Solid Edge is available in Design and Drafting, Foundation, Classic or Premium. The "Premium" package includes all of the features of "Classic" plus mechanical and electrical routing sof ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

CADDS

Computervision, Inc. (CV) was an early pioneer in Computer Aided Design and Manufacturing (CAD/ CAM). Computervision was founded in 1969 by Marty Allen and Philippe Villers, and headquartered in Bedford, Massachusetts, United States. Its early products were built on a Data General Nova platform. Starting around 1975, Computervision built its own "CGP" (Computervision Graphics Processor) Nova-compatible 16-bit computers with added instructions optimized for graphics applications and using its own operating system known as Computervision Graphic Operating System (CGOS). In the 1980s, Computervision rewrote their code to operate on Unix-based platforms. Computervision was acquired by Prime Computer in 1988 for $434 million. Prime subsequently adopted the Computervision name. On December 12, 1998 Parametric Technology Corporation acquired Computervision. CADDS product history Computervision's first product, CADDS-1, was aimed at the printed circuit board layout and 2-D drafting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SolidWorks

SolidWorks is a solid modeling computer-aided design (CAD) and computer-aided engineering (CAE) application published by Dassault Systèmes. According to the publisher, over two million engineers and designers at more than 165,000 companies were using SolidWorks as of 2013. According to the company, fiscal year 2011–12 revenue for SolidWorks totaled $483 million. History SolidWorks Corporation was founded in December 1993 by Massachusetts Institute of Technology graduate Jon Hirschtick. Hirschtick used $1 million he had made while a member of the MIT Blackjack Team to set up the company. Initially based in Waltham, Massachusetts, United States, Hirschtick recruited a team of engineers with the goal of building 3D CAD software that was easy-to-use, affordable, and available on the Windows desktop. Operating later from Concord, Massachusetts, SolidWorks released its first product ''SolidWorks 95'', in November 1995. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Parasolid

Parasolid is a geometric modeling kernel originally developed by Shape Data Limited, now owned and developed by Siemens Digital Industries Software. It can be licensed by other companies for use in their 3D computer graphics software products. Parasolid's capabilities include model creation and editing utilities such as Boolean modeling operators, feature modeling support, advanced surfacing, thickening and hollowing, blending and filleting and sheet modeling. It also incorporates modeling with mesh surfaces and lattices. Parasolid also includes tools for direct model editing, including tapering, offsetting, geometry replacement and removal of feature details with automated regeneration of surrounding data. Parasolid also provides wide-ranging graphical and rendering support, including hidden-line, wireframe and drafting, tessellation and model data inquiries. Parasolid parts are normally saved in XT format, which usually has the file extension .x_t. The format is documented and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ISO 10303

ISO 10303 is an ISO standard for the computer-interpretable representation and exchange of product manufacturing information. It is an ASCII-based format. Its official title is: ''Automation systems and integration — Product data representation and exchange''. It is known informally as "STEP", which stands for "Standard for the Exchange of Product model data". ISO 10303 can represent 3D objects in Computer-aided design (CAD) and related information. Overview The objective of the international standard is to provide a mechanism that is capable of describing product data throughout the life cycle of a product, independent from any particular system. The nature of this description makes it suitable not only for neutral file exchange, but also as a basis for implementing and sharing product databases and archiving. STEP can be typically used to exchange data between CAD, computer-aided manufacturing, computer-aided engineering, product data management/enterprise data modelin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |