|

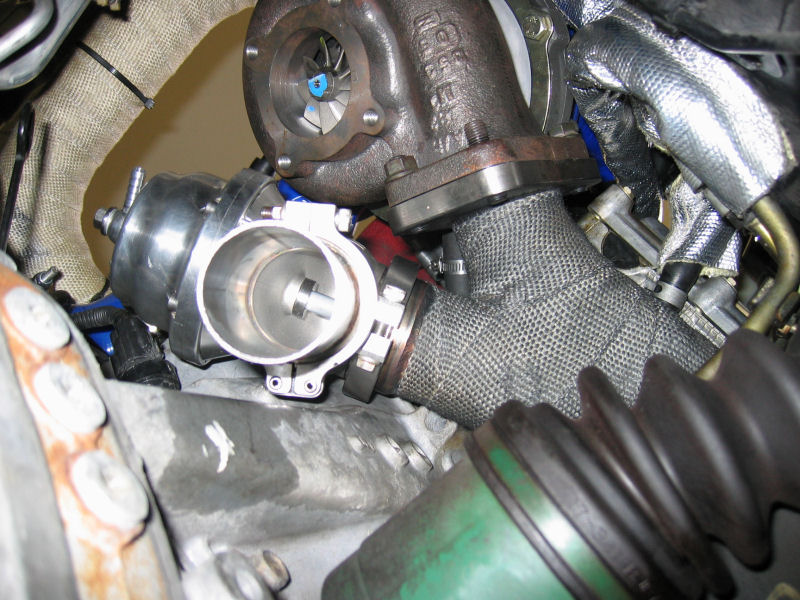

Wastegate

A wastegate is a valve that controls the flow of exhaust gases to the turbine wheel in a turbocharged engine system.Robson, D. (2018). Aircraft General Knowledge. Aviation Theory Centre Pty Ltd. . Diversion of exhaust gases regulates the turbine speed, which in turn regulates the rotating speed of the compressor. The primary function of the wastegate is to regulate the maximum boost pressure in turbocharger systems, to protect the engine and the turbocharger. One advantage of installing a remote mount wastegate to a free-float (or non-WG) turbo includes allowance for a smaller A/R turbine housing, resulting in less lag time before the turbo begins to spool and create boost. Wastegate types External An external wastegate is a separate self-contained mechanism typically used with turbochargers that do not have internal wastegates. An external wastegate requires a specially constructed turbo manifold with a dedicated runner going to the wastegate. The external wastegate may be pa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbochargers

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |

Turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a supercharger is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |

Spring (device)

A spring is an elastic object that stores mechanical energy. In everyday use the term often refers to coil springs, but there are many different spring designs. Modern springs are typically manufactured from spring steel, although some non-metallic objects like the bow are also springs. When a conventional spring, without stiffness variability features, is compressed or stretched from its resting position, it exerts an opposing force approximately proportional to its change in length (this approximation breaks down for larger deflections). The ''rate'' or ''spring constant'' of a spring is the change in the force it exerts, divided by the change in deflection of the spring. That is, it is the gradient of the force versus deflection curve. An extension or compression spring's rate is expressed in units of force divided by distance, for example or N/m or lbf/in. A torsion spring is a spring that works by twisting; when it is twisted about its axis by an angle, it produces a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Components

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy. Available energy sources include potential energy (e.g. energy of the Earth's gravitational field as exploited in hydroelectric power generation), heat energy (e.g. geothermal), chemical energy, electric potential and nuclear energy (from nuclear fission or nuclear fusion). Many of these processes generate heat as an intermediate energy form, so heat engines have special importance. Some natural processes, such as atmospheric convection cells convert environmental heat into motion (e.g. in the form of rising air currents). Mechanical energy is of particular importance in transportation, but also plays a role in many industrial processes such as cutting, grinding, crushing, and mixing. Mechanical heat engines convert heat into work via various thermodynamic processes. The internal combustion engine is perhaps the most common example of a mechanical heat engine, in whi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust Gas Recirculation

In internal combustion engines, exhaust gas recirculation (EGR) is a nitrogen oxide () emissions reduction technique used in petrol/gasoline, diesel engines and some hydrogen engines. EGR works by recirculating a portion of an engine's exhaust gas back to the engine cylinders. The exhaust gas displaces atmospheric air and reduces in the combustion chamber. Reducing the amount of oxygen reduces the amount of fuel that can burn in the cylinder thereby reducing peak in-cylinder temperatures. The actual amount of recirculated exhaust gas varies with the engine operating parameters. In the combustion cylinder, is produced by high-temperature mixtures of atmospheric nitrogen and oxygen, and this usually occurs at cylinder peak pressure. In a spark-ignition engine, an ancillary benefit of recirculating exhaust gases via an external EGR valve is an increase in efficiency, as charge dilution allows a larger throttle position and reduces associated pumping losses. Mazda's turbocharge ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dump Valve

Dump generally refers to a place for disposal of solid waste, a rubbish dump, or landfill. The word has other uses alone or in combination, and may refer to: * Midden, historically a dump for domestic waste * Dump job, a term for criminal disposal of a corpse Arts, entertainment, and media * Dump (band), an alias for the solo recordings of James McNew * Dump, tape delay (broadcasting) * Dump months, times when, due to limited box office potential, new movies are generally perceived as being of low quality and limited appeal Computing and technology * Dump (Unix), a Unix program for backing up file systems * Storage dump, inaccurately but consistently referred to as a core dump in Unix-like systems, the recorded state of the working memory of a computer program at a specific time, generally when the program has terminated abnormally (crashed) * Database dump, a record of the table structure and/or the data from a database * ROM dump or ROM image, a record of the data in a ROM, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automatic Performance Control

Automatic Performance Control (APC) was the first engine knock and boost control system. The APC was invented by Per Gillbrand at the Swedish car maker SAAB. SAAB introduced it on the turbo charged Saab H engines in 1982, and the APC was fitted to all subsequent 900 Turbos through 1993 (and 1994 convertibles), as well as 9000 Turbos through 1989. The APC was sold to Maserati to equip the carbureted Maserati Biturbo, with different settings for the Biturbo, and was known as the Maserati Automatic Boost Controller (MABC). The APC allowed a higher compression ratio (initially, 8.5:1 as opposed to 7.2:1, and, on 16-valve variants introduced in 1985, 9.0:1). This improved fuel economy and allowed the use of low-octane petrol without causing engine damage caused by knock. The APC controls boost pressure and the overall performance, specifically the rate of rise and maximum boost level - and it detects and manages harmful knock events. To control the turbocharger, the APC monito ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Teledyne Continental Motors

Continental Aerospace Technologies is an aircraft engine manufacturer located at the Brookley Aeroplex in Mobile, Alabama, United States. It was originally spun off from automobile engine manufacturer Continental Motors Company in 1929 and owned by Teledyne Technologies from 1969 until December 2010. The company is now part of Aviation Industry Corporation of China (AVIC), which is a Government of the People's Republic of China state-owned aerospace company headquartered in Beijing. Although Continental is most well known for its engines for light aircraft, it was also contracted to produce the air-cooled V-12 AV-1790-5B gasoline engine for the U.S. Army's M47 Patton tank and the diesel AVDS-1790-2A and its derivatives for the M48, M60 Patton, and Merkava main battle tanks. The company also produced engines for various independent manufacturers of automobiles, tractors, and stationary equipment (pumps, generators, and machinery drives) from the 1920s to the 1960s. History ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lycoming Engines

Lycoming Engines is a major American manufacturer of aircraft engines. With a factory in Williamsport, Pennsylvania, Lycoming produces a line of horizontally opposed, air-cooled, four, six and eight-cylinder engines including the only FAA-certified aerobatic and helicopter piston engines on the market. The company has built more than 325,000 piston aircraft engines and powers more than half the world's general aviation fleet, both rotary and fixed wing. Lycoming is an operating division of Avco Corporation, itself a subsidiary of Textron. History Sewing machines, bicycles and fashion Lycoming dates its founding to 1845 by " Madame Ellen Curtis Demorest". However, the early history of the company (especially prior to 1860) is unclear; biographer Ishbel Ross notes that the marriage of Ellen Louise Curtis to William Jennings Demorest took place in 1858, somewhat later than the purported date of establishment of the company. A few years later in New York, between c. 1860 and 1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aircraft

An aircraft is a vehicle that is able to fly by gaining support from the air. It counters the force of gravity by using either static lift or by using the dynamic lift of an airfoil, or in a few cases the downward thrust from jet engines. Common examples of aircraft include airplanes, helicopters, airships (including blimps), gliders, paramotors, and hot air balloons. The human activity that surrounds aircraft is called ''aviation''. The science of aviation, including designing and building aircraft, is called '' aeronautics.'' Crewed aircraft are flown by an onboard pilot, but unmanned aerial vehicles may be remotely controlled or self-controlled by onboard computers. Aircraft may be classified by different criteria, such as lift type, aircraft propulsion, usage and others. History Flying model craft and stories of manned flight go back many centuries; however, the first manned ascent — and safe descent — in modern times took place by larger hot-air ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

General Electric

General Electric Company (GE) is an American multinational conglomerate founded in 1892, and incorporated in New York state and headquartered in Boston. The company operated in sectors including healthcare, aviation, power, renewable energy, digital industry, additive manufacturing and venture capital and finance, but has since divested from several areas, now primarily consisting of the first four segments. In 2020, GE ranked among the Fortune 500 as the 33rd largest firm in the United States by gross revenue. In 2011, GE ranked among the Fortune 20 as the 14th most profitable company, but later very severely underperformed the market (by about 75%) as its profitability collapsed. Two employees of GE – Irving Langmuir (1932) and Ivar Giaever (1973) – have been awarded the Nobel Prize. On November 9, 2021, the company announced it would divide itself into three investment-grade public companies. On July 18, 2022, GE unveiled the brand names of the companies it will ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

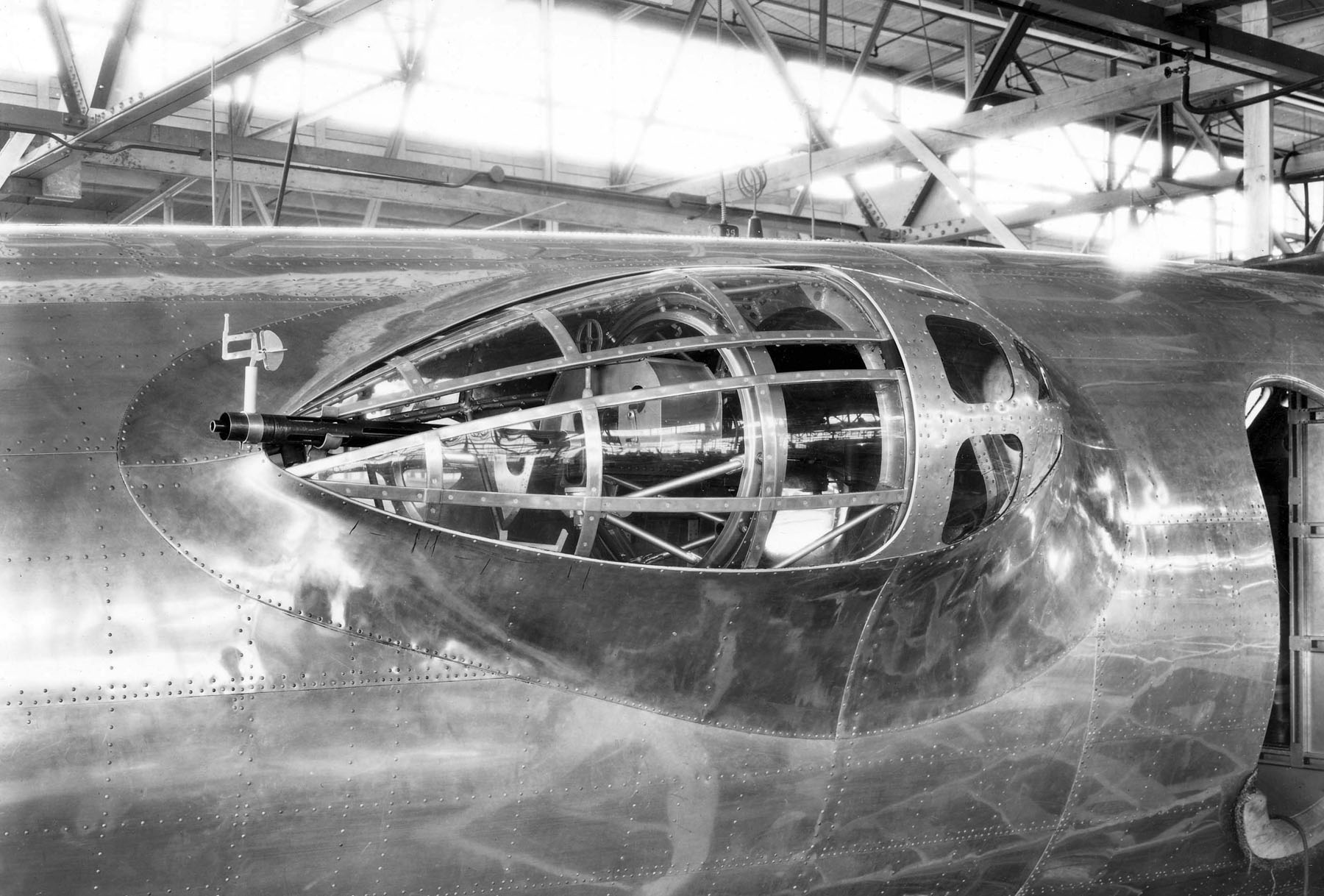

B-17 Flying Fortress

The Boeing B-17 Flying Fortress is a four-engined heavy bomber developed in the 1930s for the United States Army Air Corps (USAAC). Relatively fast and high-flying for a bomber of its era, the B-17 was used primarily in the European Theater of Operations, United States Army, European Theater of Operations and dropped more bombs than any other aircraft during World War II. It is the List of most-produced aircraft, third-most produced bomber of all time, behind the four-engined Consolidated B-24 Liberator and the multirole, twin-engined Junkers Ju 88. It was also employed as a transport, antisubmarine aircraft, drone controller, and search-and-rescue aircraft. In a USAAC competition, Boeing, Boeing's prototype Model 299/XB-17 outperformed two other entries but crashed, losing the initial 200-bomber contract to the Douglas B-18 Bolo. Still, the Air Corps ordered 13 more B-17s for further evaluation, then introduced it into service in 1938. The B-17 evolved through numerous Boei ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |