|

WorkNC

WorkNC is a Computer aided manufacturing (CAM) software developed by Sescoi for multi-axis machining. History The first version of WorkNC CAM software was released by Sescoi, in 1988. The driving forces behind the product were Bruno Marko, president of Sescoi, and Gerard Billard, R&D Innovation Manager. Salomon Group was the first customer to use WorkNC in 1988 in order to manufacture ski boots and other sports equipment. In 2002 the company released WorkNC-CAD, followed by WorkNC 5-axis in 2003 and WorkNC G3 in 2007. In 2008 Sescoi launched WorkXPlore 3D, a collaborative viewer for 3D CAD files that didn't require the original CAD application. In 2009 the company launched WorkNC Dental, a CAD/CAM software for machining of prosthetic appliances, implants or dental structures, as well as WorkNC Wire EDM, a software for Wire EDM. In 2010 Sescoi launched WorkNC-CAD Hybrid Modeling, a 3D CAD software for 3D model design, reparation, machining preparation, and surface desig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

WorkNC-CAD

WorkNC is a Computer aided manufacturing, Computer aided manufacturing (CAM) software developed by Sescoi for multi-axis machining. History The first version of WorkNC CAM software was released by Sescoi, in 1988. The driving forces behind the product were Bruno Marko, president of Sescoi, and Gerard Billard, R&D Innovation Manager. Salomon Group was the first customer to use WorkNC in 1988 in order to manufacture ski boots and other sports equipment. In 2002 the company released WorkNC-CAD, followed by WorkNC 5-axis in 2003 and WorkNC G3 in 2007. In 2008 Sescoi launched WorkXPlore 3D, a collaborative viewer for 3D CAD files that didn't require the original CAD application. In 2009 the company launched WorkNC Dental, a Computer-aided design, CAD/Computer-aided manufacturing, CAM software for machining of prosthetic appliances, implants or dental structures, as well as WorkNC Wire EDM, a software for Wire Electrical discharge machining, EDM. In 2010 Sescoi launched WorkNC-C ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

WorkNC-CAD Hybrid Modeling

WorkNC is a Computer aided manufacturing (CAM) software developed by Sescoi for multi-axis machining. History The first version of WorkNC CAM software was released by Sescoi, in 1988. The driving forces behind the product were Bruno Marko, president of Sescoi, and Gerard Billard, R&D Innovation Manager. Salomon Group was the first customer to use WorkNC in 1988 in order to manufacture ski boots and other sports equipment. In 2002 the company released WorkNC-CAD, followed by WorkNC 5-axis in 2003 and WorkNC G3 in 2007. In 2008 Sescoi launched WorkXPlore 3D, a collaborative viewer for 3D CAD files that didn't require the original CAD application. In 2009 the company launched WorkNC Dental, a CAD/CAM software for machining of prosthetic appliances, implants or dental structures, as well as WorkNC Wire EDM, a software for Wire EDM. In 2010 Sescoi launched WorkNC-CAD Hybrid Modeling, a 3D CAD software for 3D model design, reparation, machining preparation, and surface design ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

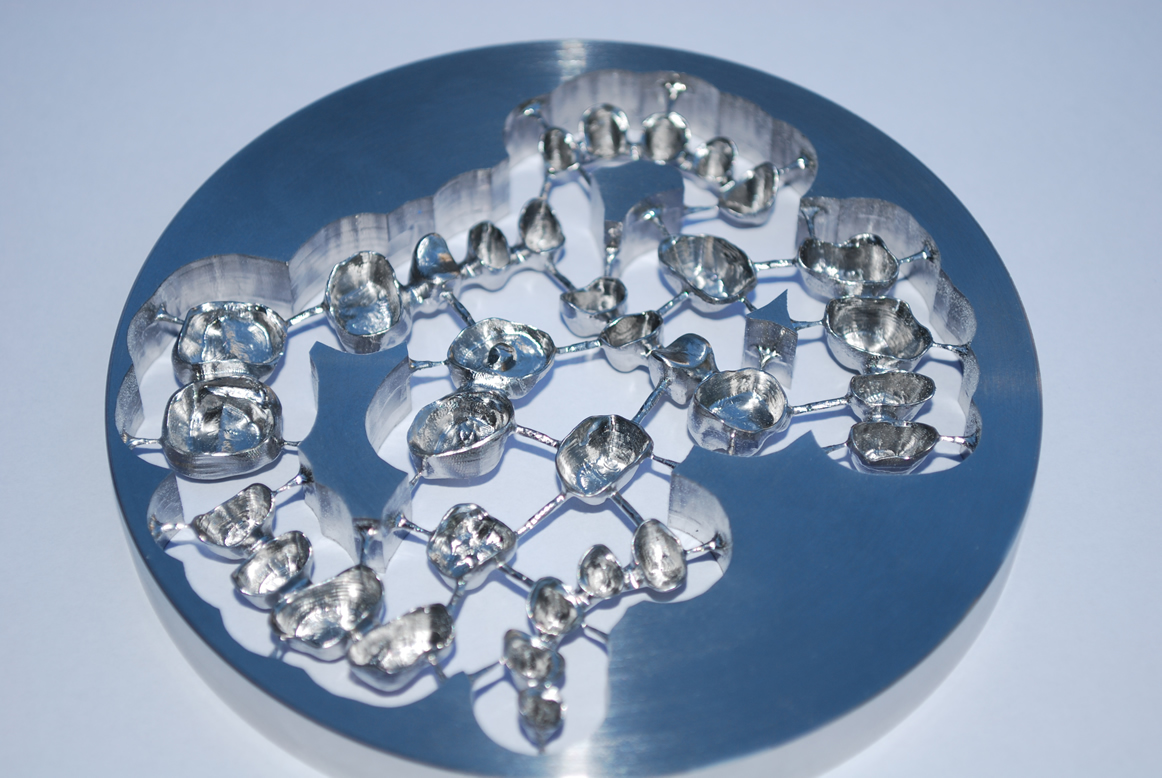

WorkNC Dental

WorkNC is a Computer aided manufacturing, Computer aided manufacturing (CAM) software developed by Sescoi for multi-axis machining. History The first version of WorkNC CAM software was released by Sescoi, in 1988. The driving forces behind the product were Bruno Marko, president of Sescoi, and Gerard Billard, R&D Innovation Manager. Salomon Group was the first customer to use WorkNC in 1988 in order to manufacture ski boots and other sports equipment. In 2002 the company released WorkNC-CAD, followed by WorkNC 5-axis in 2003 and WorkNC G3 in 2007. In 2008 Sescoi launched WorkXPlore 3D, a collaborative viewer for 3D CAD files that didn't require the original CAD application. In 2009 the company launched WorkNC Dental, a Computer-aided design, CAD/Computer-aided manufacturing, CAM software for machining of prosthetic appliances, implants or dental structures, as well as WorkNC Wire EDM, a software for Wire Electrical discharge machining, EDM. In 2010 Sescoi launched WorkNC-C ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sescoi

Sescoi is a developer of industrial software for computer-aided manufacturing, enterprise resource planning and extended enterprise productivity. Its WorkNC software is one of the market leaders in the CAD/CAM field and is used by more than 25% of companies in demanding countries such as Japan. Sescoi also develops WorkPLAN, a range of ERP software products for custom manufacturers and project based companies. As of 2011 Sescoi had more than 5000 customers and 11000 licenses sold worldwide. Sescoi and its products were acquired by Vero Software in January 2013. History Sescoi was created by Bruno Marko in 1987. The company name comes from the French acronym "Société Européenne Spécialisée en Communication Organisation et Informatique". Sescoi was an early pioneer in the development of 3D CAM software with the launch of WorkNC in 1988. WorkNC is well known for its focus on automation and ease of use. In 1992 the company launched WorkPLAN, its first ERP software for custo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

WorkXPlore 3D

PartXplore is a proprietary computer aided design (CAD) file viewer developed by Sescoi for reading, analyzing, and sharing 3D and 2D CAD files without requiring the original CAD application. It was introduced in 2008 and is supported from local Vero offices. The software is available as a viewer and an evaluation version. Functionality PartXplore serves as a collaborative viewer for 2D and 3D CAD files, allowing users to measure 3D parts and analyze various properties such as undercut areas, plane surfaces, thickness, volumes, surfaces, and weight. The software also provides dynamic cross-sectional visualization. PartXplore enables users to add dimensional and geometric measurements, annotations, and labels directly to the 3D model. Additionally, the software facilitates the sharing of 3D parts and assembly files through a standalone application that can be transmitted as an executable file. The recipient can then access and work on the 3D model received.TCT magazine, �PartX ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer Aided Manufacturing

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Manufacturing

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

WorkPLAN

WorkPLAN is a range of Enterprise Resource Planning (ERP) software products (WorkPLAN Enterprise and MyWorkPLAN) developed by Sescoi for custom manufacturers or departments who work project-based and need specialized ERP software for project management. The typical users of this ERP software are from the following industries: mold and die manufacturing, engineering, tooling, automotive, aerospace and defense. History The first version of the WorkPLAN ERP software was launched by Sescoi in 1992. Version 12, released in 2006, is the last version of this first system. Sescoi started development of a new generation of WorkPLAN ERP from 2003, which it launched as two complementary products. The first of these is MyWorkPLAN, a modular ERP for project management, launched in 2006. The second one is WorkPLAN Enterprise, a full ERP software for custom manufacturers, mold and die makers and engineering departments, launched in 2008. These two products use MySQL as a database engine, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ISO 10303

ISO 10303 is an ISO standard for the computer-interpretable representation and exchange of product manufacturing information. It is an ASCII-based format. Its official title is: ''Automation systems and integration — Product data representation and exchange''. It is known informally as "STEP", which stands for "Standard for the Exchange of Product model data". ISO 10303 can represent 3D objects in Computer-aided design (CAD) and related information. Overview The objective of the international standard is to provide a mechanism that is capable of describing product data throughout the life cycle of a product, independent from any particular system. The nature of this description makes it suitable not only for neutral file exchange, but also as a basis for implementing and sharing product databases and archiving. STEP can be typically used to exchange data between CAD, computer-aided manufacturing, computer-aided engineering, product data management/enterprise data modelin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

IGES

The Initial Graphics Exchange Specification (IGES) is a vendor-neutral file format that allows the digital exchange of information among computer-aided design (CAD) systems. It's an ASCII-based textual format. The official title of IGES is ''Digital Representation for Communication of Product Definition Data'', first published in March, 1980 by the U.S. National Bureau of Standards as NBSIR 80-1978. Many documents (like early versions of the Defense Standards MIL-PRF-28000 and MIL-STD-1840) referred to it as ASME Y14.26M, the designation of the ANSI committee that approved IGES Version 1.0. Using IGES, a CAD user can exchange product data models in the form of circuit diagrams, wireframe, freeform surface or solid modeling representations. Applications supported by IGES include traditional engineering drawings, models for analysis, and other manufacturing functions. History IGES was an initiative of the United States Air Force (USAF) Integrated Computer Aided Manufacturing (IC ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

CATIA

CATIA (, an acronym of computer-aided three-dimensional interactive application) is a multi-platform software suite for computer-aided design (CAD), computer-aided manufacturing (CAM), computer-aided engineering (CAE), 3D modeling and Product lifecycle management (PLM), developed by the French company Dassault Systèmes. Since it supports multiple stages of product development from conceptualization, design and engineering to manufacturing, it is considered a CAx-software and is sometimes referred to as a 3D Product Lifecycle Management software suite. Like most of its competition it facilitates collaborative engineering through an integrated cloud service and have support to be used across disciplines including surfacing & shape design, electrical, fluid and electronic systems design, mechanical engineering and systems engineering. Besides being used in a wide range of industries from aerospace and defence to packaging design, CATIA has been used by architect Frank Gehry to de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SolidWorks

SolidWorks is a solid modeling computer-aided design (CAD) and computer-aided engineering (CAE) application published by Dassault Systèmes. According to the publisher, over two million engineers and designers at more than 165,000 companies were using SolidWorks as of 2013. According to the company, fiscal year 2011–12 revenue for SolidWorks totaled $483 million. History SolidWorks Corporation was founded in December 1993 by Massachusetts Institute of Technology graduate Jon Hirschtick. Hirschtick used $1 million he had made while a member of the MIT Blackjack Team to set up the company. Initially based in Waltham, Massachusetts, United States, Hirschtick recruited a team of engineers with the goal of building 3D CAD software that was easy-to-use, affordable, and available on the Windows desktop. Operating later from Concord, Massachusetts, SolidWorks released its first product ''SolidWorks 95'', in November 1995. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |