|

Turbosteamer

A turbosteamer is a term used by BMW to describe a combined cycle engine. Waste heat energy from the internal combustion engine would be used to generate steam (see Waste Heat Recovery Unit) for a steam engine which would create supplemental power for the vehicle. The turbosteamer device is affixed to the exhaust and cooling system. It salvages the heat wasted in the exhaust and radiator (as much as 80% of heat energy) and uses a steam piston or turbine to relay that power to the crankshaft. The steam circuit produces and of torque at peak (for a 1.8 Straight-4 engine), yielding an estimated 15% gain in fuel efficiency. Unlike gasoline-electric hybrids, these gains increase at higher, steadier speeds. Timescale BMW has been the pioneer of this concept as early as 2000 under the direction of Dr. Raymond Freymann, and while they were designing this system to fit to most current BMW models, the technology didn't reach production. See also * COGAS * Cogeneration * Combined cycle * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Raymond Freymann

Raymond Freymann is an engineering professor and researcher, born on 30 May 1952 in Esch-sur-Alzette, Luxembourg, and has authored or co-authored more than 150 scientific publications. He has served BMW for 25 years and held the position of CEO of BMW Group Research and Technology from 2003 to 2011 Biography Raymond Freymann graduated in 1970 from the Lycée de Garcons in Esch-sur Alzette, Luxembourg. He performed his study in mechanical engineering at the Technical University of Braunschweig in Germany. He got his engineering degree in 1976 with a major in aerospace technologies. He obtained his doctor of engineering degree from the Technical University of Braunschweig in 1981 for the work he has performed at the Institute of Aeroelasticity at the DLR in Göttingen (Germany). Subsequently, he has been working as a scientist at the Flight Dynamics Laboratory at Wright Patterson Air Force Base in Dayton (Ohio). His career at BMW Group started in 1986 as head of the structural dyna ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust Heat Recovery System

An exhaust heat recovery system turns waste heat energy in exhaust gases into electric energy for batteries or mechanical energy reintroduced on the crankshaft. The technology is of increasing interest as car and heavy-duty vehicle manufacturers continue to increase efficiency, saving fuel and reducing emissions. Thermal losses of an internal combustion engine While technological improvements have greatly reduced the fuel consumption of internal combustion engines, the peak thermal efficiency of a 4-stroke Otto cycle engine is around 35%, which means that 65% of the energy released from the fuel is lost as heat. High speed Diesel cycle engines fare better with around 45% peak efficiency, but are still far from the maximum theoretical efficiency, with 55% of the fuel energy content rejected as heat. Exhaust heat recovery technologies Rankine Rankine cycle systems vaporize pressurised water using a steam generator located in the exhaust pipe. As a result of the heating by e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbo-compound Engine

A turbo-compound engine is a reciprocating engine that employs a turbine to recover energy from the exhaust gases. Instead of using that energy to drive a turbocharger as found in many high-power aircraft engines, the energy is instead sent to the output shaft to increase the total power delivered by the engine. The turbine is usually mechanically connected to the crankshaft, as on the Wright R-3350 Duplex-Cyclone, but electric and hydraulic power recovery systems have been investigated as well. As this recovery process does not increase fuel consumption, it has the effect of reducing the specific fuel consumption, the ratio of fuel use to power. Turbo-compounding was used for commercial airliners and similar long-range, long-endurance roles before the introduction of turbojet engines. Examples using the Duplex-Cyclone include the Douglas DC-7B and Lockheed L-1049 Super Constellation, while other designs did not see production use. Concept Most piston engines have a hot exhau ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Combined Cycle

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs. The principle is that after completing its cycle in the first engine, the working fluid (the exhaust) is still hot enough that a second subsequent heat engine can extract energy from the heat in the exhaust. Usually the heat passes through a heat exchanger so that the two engines can use different working fluids. By generating power from multiple streams of work, the overall efficiency can be increased by 50–60%. That is, from an overall efficiency of the system of say 34% for a simple cycle, to as much as 64% ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Waste Heat

Waste heat is heat that is produced by a machine, or other process that uses energy, as a byproduct of doing work. All such processes give off some waste heat as a fundamental result of the laws of thermodynamics. Waste heat has lower utility (or in thermodynamics lexicon a lower exergy or higher entropy) than the original energy source. Sources of waste heat include all manner of human activities, natural systems, and all organisms, for example, incandescent light bulbs get hot, a refrigerator warms the room air, a building gets hot during peak hours, an internal combustion engine generates high-temperature exhaust gases, and electronic components get warm when in operation. Instead of being "wasted" by release into the ambient environment, sometimes waste heat (or cold) can be used by another process (such as using hot engine coolant to heat a vehicle), or a portion of heat that would otherwise be wasted can be reused in the same process if make-up heat is added to the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

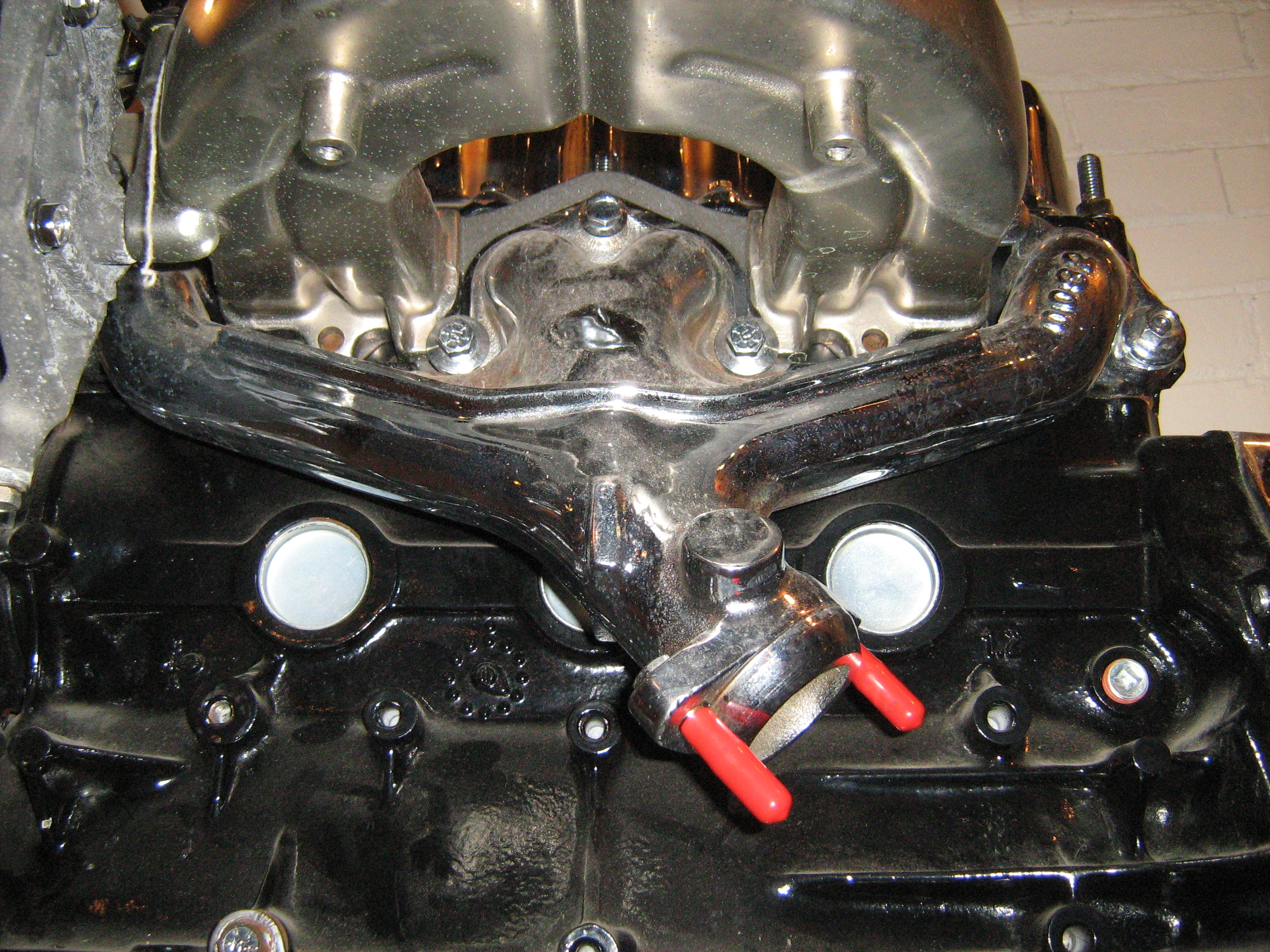

Internal Combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons ( piston engine), turbine blades (gas turbine), a rotor (Wankel engine), or a nozzle ( jet engine). This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. This replaced the external combustion engine for applications where the weight or size of an engine was more important. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1860, and the first modern internal combustion engine, known ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Waste Heat Recovery Unit

A waste heat recovery unit (WHRU) is an energy recovery heat exchanger that transfers heat from process outputs at high temperature to another part of the process for some purpose, usually increased efficiency. The WHRU is a tool involved in cogeneration. Waste heat may be extracted from sources such as hot flue gases from a diesel generator, steam from cooling towers, or even waste water from cooling processes such as in steel cooling. Heat recovery units Waste heat found in the exhaust gas of various processes or even from the exhaust stream of a conditioning unit can be used to preheat the incoming gas. This is one of the basic methods for recovery of waste heat. Many steel making plants use this process as an economic method to increase the production of the plant with lower fuel demand. There are many different commercial recovery units for the transferring of energy from hot medium space to lower one: * Recuperators: This name is given to different types of heat exchan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

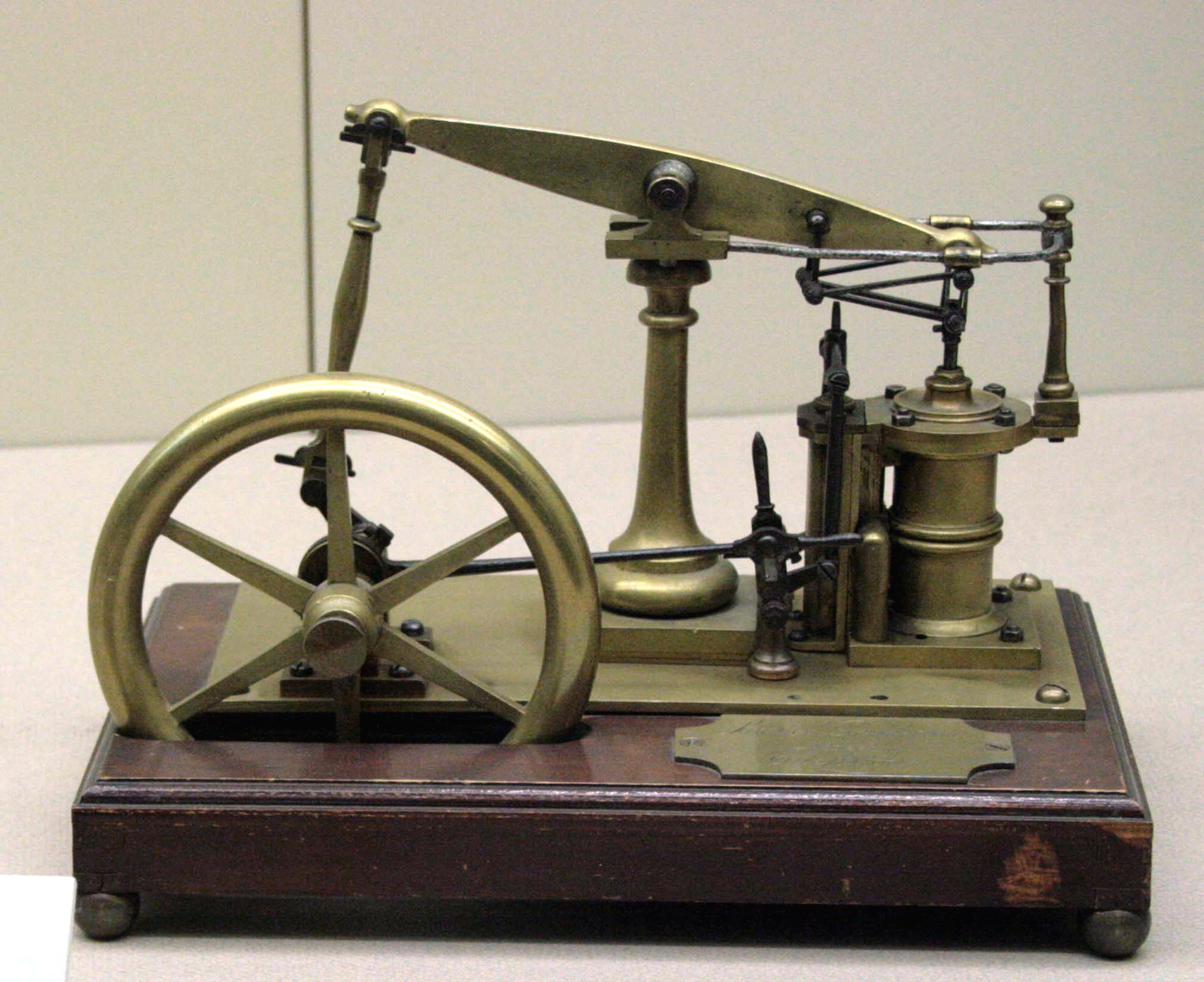

Steam Engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be transformed, by a connecting rod and crank, into rotational force for work. The term "steam engine" is generally applied only to reciprocating engines as just described, not to the steam turbine. Steam engines are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term ''steam engine'' can refer to either complete steam plants (including boilers etc.), such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, as in the beam engine and stationary steam engine. Although steam-driven devices were known as early as the aeolipile in the f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust Pipe

An exhaust system is used to guide reaction exhaust gases away from a controlled combustion inside an engine or stove. The entire system conveys burnt gases from the engine and includes one or more exhaust pipes. Depending on the overall system design, the exhaust gas may flow through one or more of: *Cylinder head and exhaust manifold *A turbocharger to increase engine power. *A catalytic converter to reduce air pollution. *A muffler (North America) / silencer (UK/India), to reduce noise. Design criteria An exhaust pipe must be carefully designed to carry toxic and/or noxious gases away from the users of the machine. Indoor generators and furnaces can quickly fill an enclosed space with poisonous exhaust gases such as hydrocarbons, carbon monoxide and nitrogen oxides, if they are not properly vented to the outdoors. Also, the gases from most types of machines are very hot; the pipe must be heat-resistant, and it must not pass through or near anything that can burn or can ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Straight-4

A straight-four engine (also called an inline-four) is a four-cylinder piston engine where cylinders are arranged in a line along a common crankshaft. The vast majority of automotive four-cylinder engines use a straight-four layout (with the exceptions of the flat-four engines produced by Subaru and Porsche) and the layout is also very common in motorcycles and other machinery. Therefore the term "four-cylinder engine" is usually synonymous with straight-four engines. When a straight-four engine is installed at an inclined angle (instead of with the cylinders oriented vertically), it is sometimes called a slant-four. Between 2005 and 2008, the proportion of new vehicles sold in the United States with four-cylinder engines rose from 30% to 47%. By the 2020 model year, the share for light-duty vehicles had risen to 59%. Design A four-stroke straight-four engine always has a cylinder on its power stroke, unlike engines with fewer cylinders where there is no power stroke occu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Efficiency

Fuel efficiency is a form of thermal efficiency, meaning the ratio of effort to result of a process that converts chemical potential energy contained in a carrier (fuel) into kinetic energy or work. Overall fuel efficiency may vary per device, which in turn may vary per application, and this spectrum of variance is often illustrated as a continuous energy profile. Non-transportation applications, such as industry, benefit from increased fuel efficiency, especially fossil fuel power plants or industries dealing with combustion, such as ammonia production during the Haber process. In the context of transport, fuel economy is the energy efficiency of a particular vehicle, given as a ratio of distance traveled per unit of fuel consumed. It is dependent on several factors including engine efficiency, transmission design, and tire design. In most countries, using the metric system, fuel economy is stated as "fuel consumption" in liters per 100 kilometers (L/100 km) or kilometer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

COGAS

Combined gas and steam (COGAS) is the name given to marine compound powerplants comprising gas and steam turbines, the latter being driven by steam generated using the heat from the exhaust of the gas turbines. In this way, some of the otherwise lost energy can be reclaimed and the specific fuel consumption of the plant can be decreased. Large (land-based) electric powerplants built using this combined cycle can reach conversion efficiencies of over 60%. If the turbines do not drive a propeller shafts directly and instead a turbo-electric transmission is used, the system is also known as COGES. COGAS differs from many other combined marine propulsion systems in that it is not intended to operate on one system alone. While this is possible, it will not operate efficiently this way, as with Combined diesel and gas systems when run solely on diesel engines. Especially COGAS should not be confused with Combined steam and gas (COSAG) power plants, which employ traditional, oil-fired ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |