|

Torque Wrench

A torque wrench is a tool used to apply a specific torque to a fastener such as a nut, bolt, or lag screw. It is usually in the form of a socket wrench with an indicating scale, or an internal mechanism which will indicate (as by 'clicking', a specific movement of the tool handle in relation to the tool head) when a specified (adjustable) torque value has been reached during application. A torque wrench is used where the tightness of screws and bolts is a crucial parameter of assembly or adjustment. It allows the operator to set the torque applied to the fastener to meet the specification for a particular application. This permits proper tension and loading of all parts. Torque screwdrivers and torque wrenches have similar purposes and may have similar mechanisms. History The first patent for a torque wrench was filed by John H. Sharp of Chicago in 1931. This wrench was referred to as a ''torque measuring wrench'' and would be classified today as an indicating torque wrenc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Walter Percy Chrysler

Walter Percy Chrysler (April 2, 1875 – August 18, 1940) was an American industrial pioneer in the automotive industry, American automotive industry executive and the founder and namesake of American Chrysler Corporation. Early life Chrysler was born in Wamego, Kansas, the son of Anna Maria Chrysler (née Breymann) and Henry Chrysler. He grew up in Ellis, Kansas, where today his boyhood home is a museum. His father was born in Chatham, Ontario, in 1850 and immigrated to the United States after 1858. A Freemason,. Chrysler began his career as a machinist and railroad mechanic in Ellis. He took correspondence courses from International Correspondence Schools in Scranton, Pennsylvania, earning a mechanical degree from the correspondence program. Ancestry Walter Chrysler's father, Henry (Hank) Chrysler, was a Canadian-American of German and Dutch ancestry. He was an American Civil War veteran who was a locomotive engineer for the Kansas Pacific Railway and its successor, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strain Gauge

A strain gauge (also spelled strain gage) is a device used to measure strain on an object. Invented by Edward E. Simmons and Arthur C. Ruge in 1938, the most common type of strain gauge consists of an insulating flexible backing which supports a metallic foil pattern. The gauge is attached to the object by a suitable adhesive, such as cyanoacrylate. As the object is deformed, the foil is deformed, causing its electrical resistance to change. This resistance change, usually measured using a Wheatstone bridge, is related to the strain by the quantity known as the gauge factor. History Edward E. Simmons and Professor Arthur C. Ruge independently invented the strain gauge. Simmons was involved in a research project by Dätwyler and Clark at Caltech between 1936 and 1938. They researched the stress-strain behavior of metals under shock loads. Simmon came up with an original way to measure the force introduced into the sample by equipping a dynamometer with fine resistance w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ratchet (device)

A ratchet (occasionally spelled rachet) is a mechanical device that allows continuous linear or rotary motion in only one direction while preventing motion in the opposite direction. Ratchets are widely used in machinery and tools. The word ''ratchet'' is also used informally to refer to a ratcheting socket wrench. __TOC__ Theory of operation A ratchet consists of a round gear or a linear rack with teeth, and a pivoting, spring-loaded finger called a '' pawl'' (or ''click'', in clocks and watches) that engages the teeth. The teeth are uniform but are usually asymmetrical, with each tooth having a moderate slope on one edge and a much steeper slope on the other edge. When the teeth are moving in the unrestricted (i.e. forward) direction, the pawl easily slides up and over the gently sloped edges of the teeth, with a spring forcing it (often with an audible 'click') into the depression between the teeth as it passes the tip of each tooth. When the teeth move in the opposite ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soil Pipe

Soil, also commonly referred to as earth or dirt, is a mixture of organic matter, minerals, gases, liquids, and organisms that together support life. Some scientific definitions distinguish ''dirt'' from ''soil'' by restricting the former term specifically to displaced soil. Soil consists of a solid phase of minerals and organic matter (the soil matrix), as well as a porous phase that holds gases (the soil atmosphere) and water (the soil solution). Accordingly, soil is a three-state system of solids, liquids, and gases. Soil is a product of several factors: the influence of climate, relief (elevation, orientation, and slope of terrain), organisms, and the soil's parent materials (original minerals) interacting over time. It continually undergoes development by way of numerous physical, chemical and biological processes, which include weathering with associated erosion. Given its complexity and strong internal connectedness, soil ecologists regard soil as an ecosystem. Most ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drills

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to increased efficiency and ease of use. Drills are commonly used in woodworking, metalworking, construction, machine tool fabrication, construction and utility projects. Specially designed versions are made for miniature applications. History Around 35,000 BC, ''Homo sapiens'' discovered the benefits of the application of rotary tools. This would have rudimentarily consisted of a pointed rock being spun between the hands to bore a hole through another material. This led to the hand drill, a smooth stick, that was sometimes attached to flint point, and was rubbed between the palms. This was used by many ancient civilizations around the world including the Mayans. The earliest perforated artifacts, such as bone, ivory, shells, and antlers ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw Thread

A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a ''straight'' thread and the latter called a ''tapered'' thread. A screw thread is the essential feature of the screw as a simple machine and also as a threaded fastener. The mechanical advantage of a screw thread depends on its ''lead'', which is the linear distance the screw travels in one revolution. In most applications, the lead of a screw thread is chosen so that friction is sufficient to prevent linear motion being converted to rotary, that is so the screw does not slip even when linear force is applied, as long as no external rotational force is present. This characteristic is essential to the vast majority of its uses. The tightening of a fastener's screw thread is comparable to driving a wedge into a gap until it sticks fast ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spring (device)

A spring is an elastic object that stores mechanical energy. In everyday use the term often refers to coil springs, but there are many different spring designs. Modern springs are typically manufactured from spring steel, although some non-metallic objects like the bow are also springs. When a conventional spring, without stiffness variability features, is compressed or stretched from its resting position, it exerts an opposing force approximately proportional to its change in length (this approximation breaks down for larger deflections). The ''rate'' or ''spring constant'' of a spring is the change in the force it exerts, divided by the change in deflection of the spring. That is, it is the gradient of the force versus deflection curve. An extension or compression spring's rate is expressed in units of force divided by distance, for example or N/m or lbf/in. A torsion spring is a spring that works by twisting; when it is twisted about its axis by an angle, it produc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ball Detent

A ball detent is a simple mechanical arrangement used to hold a moving part in a temporarily fixed position relative to another part. Usually the moving parts slide with respect to each other, or one part rotates within the other. The ball is a single, usually metal sphere, sliding within a bored cylinder, against the pressure of a spring, which pushes the ball against the other part of the mechanism, which carries the detent - which can be as simple as a hole of smaller diameter than the ball. When the hole is in line with the cylinder, the ball is partially pushed into the hole under spring pressure, holding the parts at that position. Additional force applied to the moving parts will compressing the spring, causing the ball to be depressed back into its cylinder, and allowing the parts to move to another position. Applications Ball detents are commonly found in the selector mechanism of a gearbox, holding the selector rods in the correct position to engage the desired gear. O ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

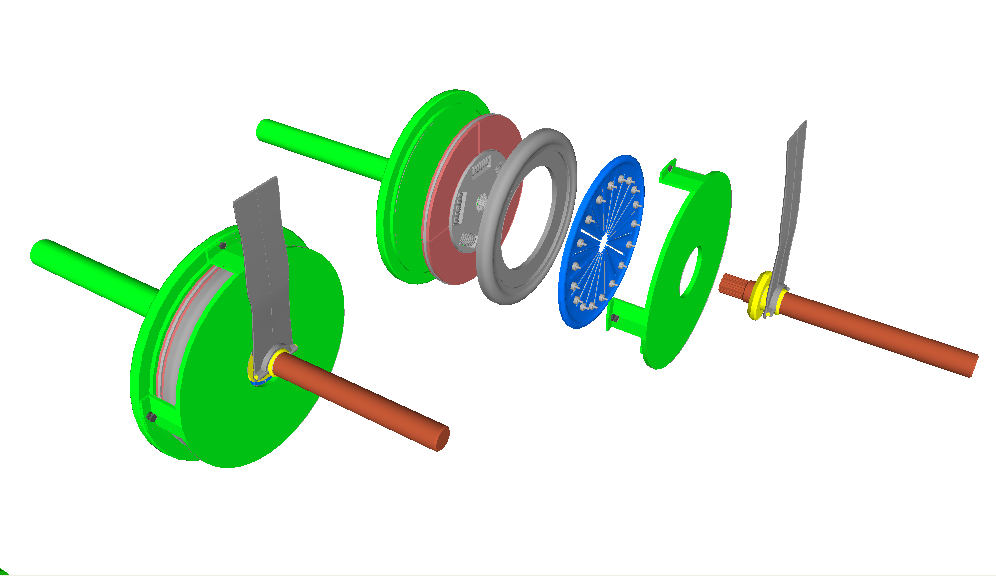

Clutch

A clutch is a mechanical device that engages and disengages power transmission, especially from a drive shaft to a driven shaft. In the simplest application, clutches connect and disconnect two rotating shafts (drive shafts or line shafts). In these devices, one shaft is typically attached to an engine or other power unit (the driving member), while the other shaft (the driven member) provides output power for work. Typically the motions involved are rotary, but linear clutches also exist. In a motor vehicle, the clutch acts as a mechanical linkage between the engine and transmission, and briefly disconnects, or separates the engine from the transmission system. This disconnects the drive wheels whenever the clutch pedal is depressed, allowing the driver to smoothly change gears. In a torque-controlled drill, for instance, one shaft is driven by a motor, and the other drives a drill chuck. The clutch connects the two shafts so they may be locked together and spin at the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knurling

Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material. Etymology The terms ''knurl'' and ''knurled'' are from an earlier ''knur'' ‘knot in wood’ and the diminutive ''-le'', from Middle English ''knaur'' or ''knarre'' ‘knot in wood; twisted rock; crag’. This descends from Old English ''cnearra'' but the vowel in Middle English may have been influenced by Old Norse ''knǫrr'' ‘merchant ship’ which was known as ''cnearr'' in Old English. The modern ''gnarl'' is a back-formation of ''gnarled'' which itself is first attested in Shakespeare’s works and is apparently a variant of ''knurled''. Uses The operation is performed for producing indentations on a part of a workpiece. Knurling allows hands or fingers to get a better grip on the knurled object than would be provided by the originally smooth metal surface. Occasionally, the knurled pattern is a series of straight ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |