|

Tensometer

A universal testing machine (UTM), also known as a universal tester, materials testing machine or materials test frame, is used to test the tensile strength and compressive strength of materials. An earlier name for a tensile testing machine is a tensometer. The "universal" part of the name reflects that it can perform many standard tensile and compression tests on materials, components, and structures (in other words, that it is versatile). Components Several variations are in use. Common components include: * Load frame - Usually consisting of two strong supports for the machine. Some small machines have a single support. * Load cell - A force transducer or other means of measuring the load is required. Periodic calibration is usually required by governing regulations or quality system. * Cross head - A movable cross head (crosshead) is controlled to move up or down. Usually this is at a constant speed: sometimes called a ''constant rate of extension'' (CRE) machine. So ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extensometer

An extensometer is a device that is used to measure changes in the length of an object. It is useful for stress-strain measurements and tensile tests. Its name comes from "extension-meter". It was invented by Charles Huston who described it in an article in the ''Journal of the Franklin Institute'' in 1879. Huston later gave the rights to Fairbanks & Ewing, a major manufacturer of testing machines and scales. Types There are two main types of extensometers: ''contact'' and ''non-contact''. Contact ''Contact extensometers'' have been used for many years and are also subdivided into two further categories. The first type of contact extensometer is called a ''clip-on'' extensometer. These devices are used for applications where high precision strain measurement is required (most ASTM based tests). They come in many configurations and can measure displacements from very small to relatively large (less than a mm to over 100 mm). They have the advantage of lower cost and ea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Universal Testing Machine

A universal testing machine (UTM), also known as a universal tester, materials testing machine or materials test frame, is used to test the tensile strength and compressive strength of materials. An earlier name for a tensile testing machine is a tensometer. The "universal" part of the name reflects that it can perform many standard tensile and compression tests on materials, components, and structures (in other words, that it is versatile). Components Several variations are in use. Common components include: * Load frame - Usually consisting of two strong supports for the machine. Some small machines have a single support. * Load cell - A force transducer or other means of measuring the load is required. Periodic calibration is usually required by governing regulations or quality system. * Cross head - A movable cross head (crosshead) is controlled to move up or down. Usually this is at a constant speed: sometimes called a ''constant rate of extension'' (CRE) machine. So ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Universal Testing Machine

A universal testing machine (UTM), also known as a universal tester, materials testing machine or materials test frame, is used to test the tensile strength and compressive strength of materials. An earlier name for a tensile testing machine is a tensometer. The "universal" part of the name reflects that it can perform many standard tensile and compression tests on materials, components, and structures (in other words, that it is versatile). Components Several variations are in use. Common components include: * Load frame - Usually consisting of two strong supports for the machine. Some small machines have a single support. * Load cell - A force transducer or other means of measuring the load is required. Periodic calibration is usually required by governing regulations or quality system. * Cross head - A movable cross head (crosshead) is controlled to move up or down. Usually this is at a constant speed: sometimes called a ''constant rate of extension'' (CRE) machine. So ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tensile Strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials the ultimate tensile strength is close to the yield point, whereas in ductile materials the ultimate tensile strength can be higher. The ultimate tensile strength is usually found by performing a tensile test and recording the engineering stress versus strain. The highest point of the stress–strain curve is the ultimate tensile strength and has units of stress. The equivalent point for the case of compression, instead of tension, is called the compressive strength. Tensile strengths are rarely of any consequence in the design of ductile members, but they are important with brittle members. They are tabulated for common materials such as alloys, composite materials, ceramics, plastics, and wood. Definition The ultimate tensile streng ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue Testing

Fatigue testing is a specialised form of mechanical testing that is performed by applying cyclic loading to a ''coupon'' or structure. These tests are used either to generate fatigue life and crack growth data, identify critical locations or demonstrate the safety of a structure that may be susceptible to fatigue. Fatigue tests are used on a range of components from coupons through to full size test articles such as automobiles and aircraft. Fatigue tests on coupons are typically conducted using servo hydraulic test machines which are capable of applying large ''variable amplitude'' cyclic loads. ''Constant amplitude'' testing can also be applied by simpler oscillating machines. The ''fatigue life'' of a coupon is the number of cycles it takes to break the coupon. This data can be used for creating stress-life or strain-life curves. The rate of crack growth in a coupon can also be measured, either during the test or afterward using fractography. Testing of coupons can also b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Test Fixture

A test fixture is an environment used to consistently test some item, device, or piece of software. Test fixtures can be found when testing electronics, software and physical devices. Electronics In testing electronic equipment such as circuit boards, electronic components, and chips, a test fixture is a device or setup designed to hold the device under test in place and allow it to be tested by being subjected to controlled electronic test signals. Examples are a bed of nails tester or SmartFixture. Electronics Test Fixture.jpg, Side connectors, centering pins, test needles, pre-centering parts. Functional Test Fixture for electroncis.jpg, A functional test fixture is a complex device to interface the device under test (DUT) to the automatic test equipment (ATE). Software A software test fixture sets up a system for the software testing process by initializing it, thereby satisfying any preconditions the system may have. For example, the Ruby on Rails web framework uses ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Press

A hydraulic press is a machine press using a hydraulic cylinder to generate a compressive force. It uses the hydraulic equivalent of a mechanical lever, and was also known as a Bramah press after the inventor, Joseph Bramah, of England. He invented and was issued a patent on this press in 1795. As Bramah (who is also known for his development of the flush toilet) installed toilets, he studied the existing literature on the motion of fluids and put this knowledge into the development of the press. Main principle The hydraulic press depends on Pascal's principle-the pressure throughout a closed system is constant. One part of the system is a piston acting as a pump, with a modest mechanical force acting on a small cross-sectional area; the other part is a piston with a larger area which generates a correspondingly large mechanical force. Only small-diameter tubing (which more easily resists pressure) is needed if the pump is separated from the press cylinder. Pascal's law: Pressu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

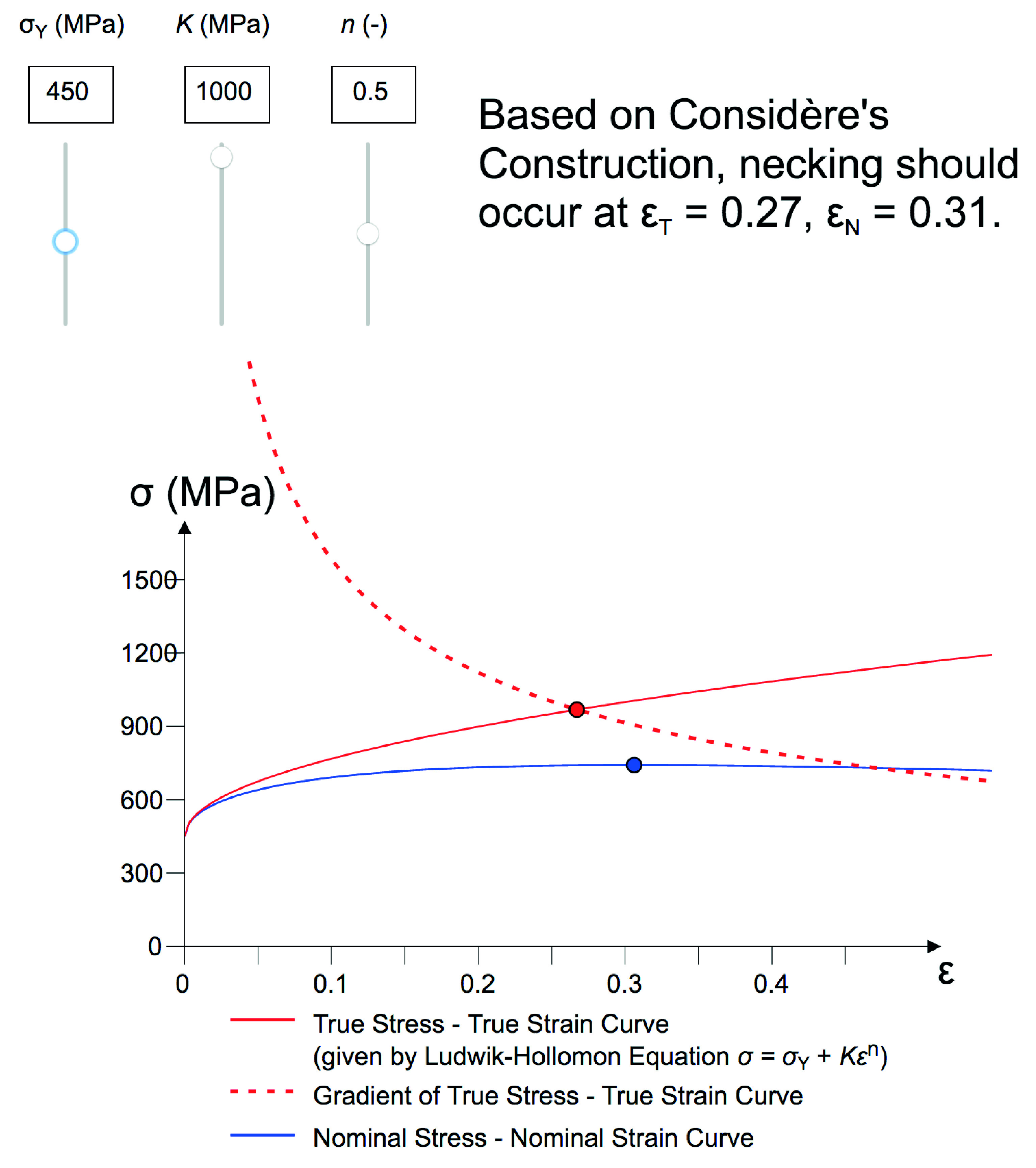

Necking (engineering)

Necking, in engineering or materials science, is a mode of tensile deformation where relatively large amounts of strain localize disproportionately in a small region of the material. The resulting prominent decrease in local cross-sectional area provides the basis for the name "neck". Because the local strains in the neck are large, necking is often closely associated with yielding, a form of plastic deformation associated with ductile materials, often metals or polymers. Once necking has begun, the neck becomes the exclusive location of yielding in the material, as the reduced area gives the neck the largest local stress. Formation Necking results from an instability during tensile deformation when the cross-sectional area of the sample decreases by a greater proportion than the material strain hardens.Armand Considèrepublished the basic criterion for necking in 1885, in the context of the stability of large scale structures such as bridges. Three concepts provide the frame ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Young's Modulus

Young's modulus E, the Young modulus, or the modulus of elasticity in tension or compression (i.e., negative tension), is a mechanical property that measures the tensile or compressive stiffness of a solid material when the force is applied lengthwise. It quantifies the relationship between tensile/compressive stress \sigma (force per unit area) and axial strain \varepsilon (proportional deformation) in the linear elastic region of a material and is determined using the formula: E = \frac Young's moduli are typically so large that they are expressed not in pascals but in gigapascals (GPa). Example: * Silly Putty (increasing pressure: length increases quickly, meaning tiny E) * Aluminum (increasing pressure: length increases slowly, meaning high E) Higher Young's modulus corresponds to greater (lengthwise) stiffness. Although Young's modulus is named after the 19th-century British scientist Thomas Young, the concept was developed in 1727 by Leonhard Euler. The first experime ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Modulus Of Elasticity

An elastic modulus (also known as modulus of elasticity) is the unit of measurement of an object's or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it. The elastic modulus of an object is defined as the slope of its stress–strain curve in the elastic deformation region: A stiffer material will have a higher elastic modulus. An elastic modulus has the form: :\delta \ \stackrel\ \frac where stress is the force causing the deformation divided by the area to which the force is applied and strain is the ratio of the change in some parameter caused by the deformation to the original value of the parameter. Since strain is a dimensionless quantity, the units of \delta will be the same as the units of stress. Specifying how stress and strain are to be measured, including directions, allows for many types of elastic moduli to be defined. The three primary ones are: # ''Young's modulus'' (E) describes tensile and compressive ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Standards Organization

A standards organization, standards body, standards developing organization (SDO), or standards setting organization (SSO) is an organization whose primary function is developing, coordinating, promulgating, revising, amending, reissuing, interpreting, or otherwise contributing to the usefulness of technical standards to those who employ them. Such an organization works to create uniformity across producers, consumers, government agencies, and other relevant parties regarding terminology, product specifications (e.g. size, including units of measure), protocols, and more. Its goals could include ensuring that Company A's external hard drive works on Company B's computer, an individual's blood pressure measures the same with Company C's sphygmomanometer as it does with Company D's, or that all shirts that should not be ironed have the same icon (a clothes iron crossed out with an X) on the label. Most standards are voluntary in the sense that they are offered for adoption by people ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |