|

Thermoplastic Vulcanizates

Thermoplastic vulcanizates (TPV) are dynamically vulcanized alloys consisting mostly of fully cured EPDM rubber particles encapsulated in a polypropylene (PP) matrix. They are part of the thermoplastic elastomer (TPE) family of polymers but are closest in elastomeric properties to EPDM thermoset rubber, combining the characteristics of vulcanized rubber with the processing properties of thermoplastics. There are almost 100 grades in the S portfolio that are used globally in the automotive, household appliance, electrical, construction, and healthcare markets. The name Santoprene was trademarked in 1977 by Monsanto, and the trademark is now owned by Celanese. Similar material is available from Elastron and others. Overview TPV was created after several years of research and development aimed at finding new materials for injection-molded tires. Although the search for a new tire material was unsuccessful, it resulted in the development of TPV, which combines the characteristics of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity (optics), opacity, and lustre (mineralogy), luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength. Alloys are defined by a metallic bonding character. The alloy constituents are usually measured by mass percentage for practical applications, and in Atomic ratio, atomic fraction for basic science studies. Alloys are usually classified as substitutional or interstitial alloys, depending on the atomic arrangement that forms the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Resistance

The chemical resistance of a material or surface can be determined in compliance with ISO 2812 Paints and varnishes – Determination of resistance to liquids – Part 1: Immersion in liquids other than water (ISO 2812-1:2007); German Version EN ISO 2812-1:2007 or Part 4: Spotting methods (ISO 2812-4:2007); German Version EN ISO 2812-4:2007. With these methods, a material or surface is exposed to the relevant chemical for a longer, defined period of time and the relevant area then inspected microscopically. Possible changes which could occur include: * Discoloration * Alteration in the degree of shine * Softening * Swelling * Detachment of coatings * Blistering On completion of the defined test period, any residues of test liquid are removed and the material surface assessed and analyzed for visible alterations in accordance with DIN EN ISO 4628-1 to -5.ISO 4628-5 Paints and varnishes - Evaluation of degradation of coatings - De-signation of quantity and size of defects, and of inte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extrusion

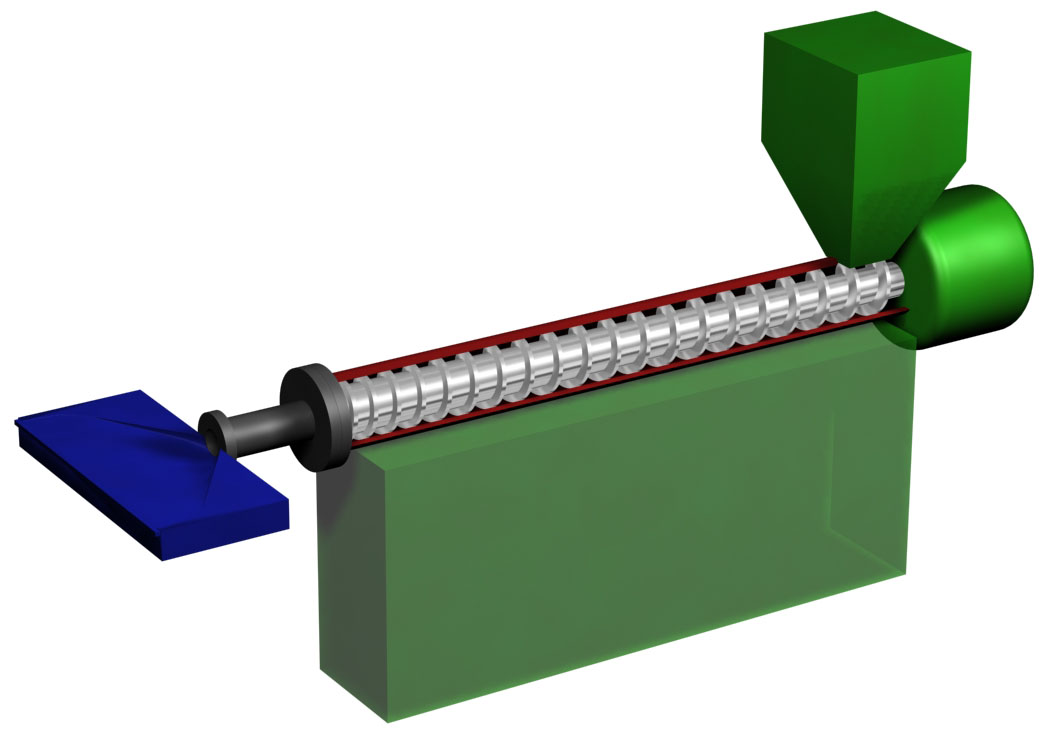

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal bars and tubes are also often drawn. Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). It can be done with hot or cold material. Commonly extruded materials ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blow Molding

Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding. The blow molding process begins with softening plastic by heating a preform or parison. The parison is a tube-like piece of plastic with a hole in one end through which compressed air can enter. The plastic workpiece is then clamped into a mold and air is blown into it. The air pressure inflates the plastic which conforms to the mold. Once the plastic has cooled and hardened the mold opens and the part is ejected. Water channels within the mold assist cooling. History The process principle comes from the idea of glassblowing. Enoch Ferngren and William Kopitke produced a blow molding machine and sold it to Hartford Empire Company in 1938. This was the beginning of the commercial blow mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coextrusion

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into a shape that hardens during cooling. History The first precursors to the modern extruder were developed in the early 19th century. In 1820, Thomas Hancock invented a rubber "masticator" designed to reclaim processed rubber scraps, and in 1836 Edwin Chaffee developed a two-roller machine to mix additives into rubber. The first thermoplastic extru ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Harmonization

In music, harmonization is the chordal accompaniment to a line or melody: "Using chords and melodies together, making harmony by stacking scale tones as triads". A harmonized scale can be created by using each note of a musical scale as a root note for a chord and then by taking other tones within the scale building the rest of a chord. For example, using an Ionian (major scale) * the root note would become the I major chord, * the second note the ii minor chord, * the third note the iii minor chord, * the fourth note the IV major chord, * the fifth note the V major chord (or even a dominant 7th), * the sixth note the vi minor chord, * the seventh note the vii diminished chord and * the octave would be a I major chord. Using the minor (aeolian mode) one would have: * i minor, * ii diminished, * ()III major, * iv minor, * v minor, * ()VI major, * ()VII major and * the i minor an octave higher. Reharmonization Reharmonization is the technique of taking an existing melodic l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electron Microscope

An electron microscope is a microscope that uses a beam of accelerated electrons as a source of illumination. As the wavelength of an electron can be up to 100,000 times shorter than that of visible light photons, electron microscopes have a higher resolving power than light microscopes and can reveal the structure of smaller objects. A scanning transmission electron microscope has achieved better than 50 pm resolution in annular dark-field imaging mode and magnifications of up to about 10,000,000× whereas most light microscopes are limited by diffraction to about 200 nm resolution and useful magnifications below 2000×. Electron microscopes use shaped magnetic fields to form electron optical lens systems that are analogous to the glass lenses of an optical light microscope. Electron microscopes are used to investigate the ultrastructure of a wide range of biological and inorganic specimens including microorganisms, cells, large molecules, biopsy samples, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Atomic Force Microscopy

Atomic force microscopy (AFM) or scanning force microscopy (SFM) is a very-high-resolution type of scanning probe microscopy (SPM), with demonstrated resolution on the order of fractions of a nanometer, more than 1000 times better than the optical diffraction limit. Overview Atomic force microscopy (AFM) is a type of scanning probe microscopy (SPM), with demonstrated resolution on the order of fractions of a nanometer, more than 1000 times better than the optical diffraction limit. The information is gathered by "feeling" or "touching" the surface with a mechanical probe. Piezoelectric elements that facilitate tiny but accurate and precise movements on (electronic) command enable precise scanning. Despite the name, the Atomic Force Microscope does not use the Nuclear force. Abilities The AFM has three major abilities: force measurement, topographic imaging, and manipulation. In force measurement, AFMs can be used to measure the forces between the probe and the sample as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Syringe

A syringe is a simple reciprocating pump consisting of a plunger (though in modern syringes, it is actually a piston) that fits tightly within a cylindrical tube called a barrel. The plunger can be linearly pulled and pushed along the inside of the tube, allowing the syringe to take in and expel liquid or gas through a discharge orifice at the front (open) end of the tube. The open end of the syringe may be fitted with a hypodermic needle, a nozzle or tubing to direct the flow into and out of the barrel. Syringes are frequently used in clinical medicine to administer injections, infuse intravenous therapy into the bloodstream, apply compounds such as glue or lubricant, and draw/measure liquids. There are also prefilled syringes (disposable syringes marketed with liquid inside). The word "syringe" is derived from the Greek σύριγξ ('' syrinx'', meaning "Pan flute", "tube"). Medical syringes Sectors in the syringe and needle market include disposable and safe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gasket

Some seals and gaskets A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly. Gaskets allow for "less-than-perfect" mating surfaces on machine parts where they can fill irregularities. Gaskets are commonly produced by cutting from sheet materials. Given the potential cost and safety implications of faulty or leaking gaskets, it is critical that the correct gasket material is selected to fit the needs of the application. Gaskets for specific applications, such as high pressure steam systems, may contain asbestos. However, due to health hazards associated with asbestos exposure, non-asbestos gasket materials are used when practical. It is usually desirable that the gasket be made from a material that is to some de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Caster

A caster (or castor) is an undriven wheel that is designed to be attached to the bottom of a larger object (the "vehicle") to enable that object to be moved. Casters are used in numerous applications, including shopping carts, office chairs, toy wagons, hospital beds, and material handling equipment. High capacity, heavy duty casters are used in many industrial applications, such as platform trucks, carts, assemblies, and tow lines in plants. Types Casters may be fixed to roll along a straight line path, or mounted on a pivot or pintle such that the wheel will automatically align itself to the direction of travel. Rigid casters A basic, rigid caster consists of a wheel mounted to a stationary fork. The orientation of the fork, which is fixed relative to the vehicle, is determined when the caster is mounted to the vehicle. An example of this is the wheels found at the rear of a shopping cart in North America. Rigid casters tend to restrict vehicle motion so that the vehicle t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Celanese

Celanese Corporation, formerly known as Hoechst Celanese, is an American technology and specialty materials company headquartered in Irving, Texas. A Fortune 500 corporation, the company is the world’s leading producer of acetic acid, producing about 1.95 million tonnes per year, representing approximately 25% of global production. Celanese is also the world's largest producer of vinyl acetate monomer (VAM). Celanese operates 25 production plants and six research centers in 11 countries, mainly in North America, Europe, and Asia. The company owns and operates the world's three largest acetic acid plants: one in the Clear Lake area of Pasadena, Texas, one on Jurong Island in Singapore, and a third in Nanjing, China. History In 1918, the American Cellulose & Chemical Manufacturing Company (known as Amcelle) was founded in New York City by Swiss chemist Camille Dreyfus. The American Cellulose and Chemical Manufacturing Co. Ltd plant in Cumberland, Maryland, was set up dur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |