|

Terminal Ballistics

Terminal ballistics is a sub-field of ballistics concerned with the behavior and effects of a projectile when it hits and transfers its energy to a target. This field is usually cited in forensic ballistics. Bullet design (as well as the velocity of impact) largely determines the effectiveness of penetration. General The concept of terminal ballistics can be applied to any projectile striking a target. Much of the topic specifically regards the effects of small arms fire striking live targets, and a projectile's ability to incapacitate or eliminate a target. Common factors include bullet mass, composition, velocity, and shape. Firearm projectiles Class of projectile Projectiles are primarily designed for compatibility with the constraints of the device used to launch them, and secondarily according to some balance of logistical practicality, practicable accuracy, and terminal effect. Prior to the development of rifling, the majority of projectiles purpose-built for shooting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Hollow-point Bullet

A hollow-point bullet is a type of expanding bullet which expands on impact with a soft target, transferring more or all of the projectile's energy into the target over a shorter distance. Hollow-point bullets are used for controlled penetration, where overpenetration could cause collateral damage (such as aboard an aircraft). In target shooting, they are used for greater accuracy due to the larger meplat. They are more accurate and predictable compared to pointed bullets which, despite having a higher ballistic coefficient (BC), are more sensitive to bullet harmonic characteristics and wind deflection. Plastic-tipped bullets are a type of (rifle) bullet meant to confer the aerodynamic advantage of the Spitzer bullet (for example, see very-low-drag bullet) and the stopping power of hollow-point bullets. Gunshot wounds from hollow-point bullets can be very painful; due to this, they have been banned from use in wartime. They may leave fragments difficult to remove ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Sniper Rifle

A sniper rifle is a high-precision, long range shooting, long-range rifle. Requirements include high accuracy, reliability, mobility, concealment, and optics, for anti-personnel weapon, anti-personnel, anti-materiel rifle, anti-materiel and surveillance uses by military snipers. The modern sniper rifle is a portable shoulder-fired rifle with either a bolt action or semi-automatic firearm, semi-automatic action (firearms), action, fitted with a telescopic sight for extreme accuracy and chambered for a high-ballistic performance Centerfire ammunition, centerfire cartridge (firearms), cartridge. History The Whitworth rifle was arguably the first long-range sniper rifle in the world. Designed in 1854 by Sir Joseph Whitworth, a prominent British engineer, it used barrels with hexagonal polygonal rifling, which meant that the projectile did not have to "bite" into the rifling grooves as with conventional rifling. His rifle was far more accurate than the Pattern 1853 Enfield, which ha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

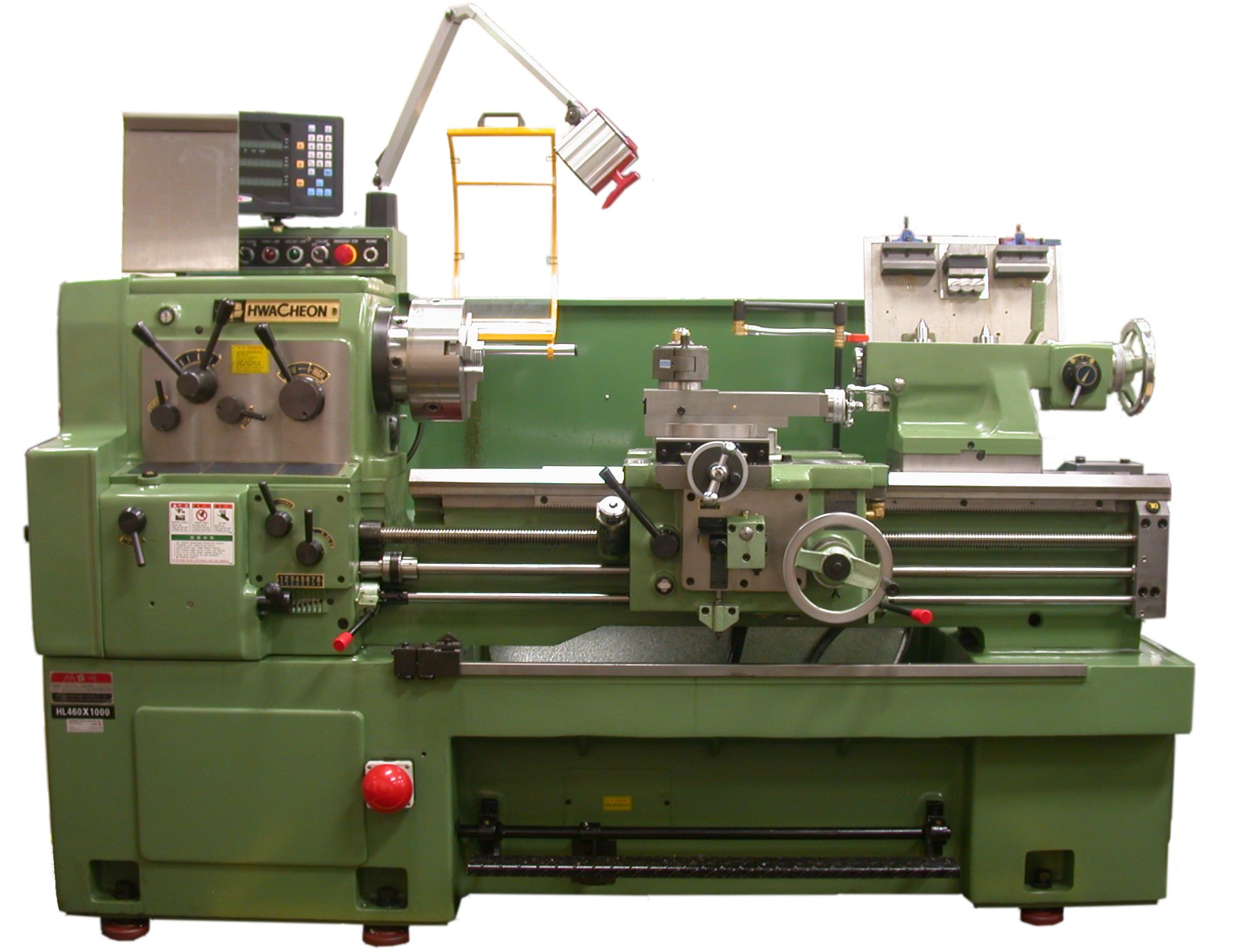

Lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Numerical Control

Computer numerical control (CNC) or CNC machining is the automated control of machine tools by a computer. It is an evolution of numerical control (NC), where machine tools are directly managed by data storage media such as punched cards or punched tape. Because CNC allows for easier programming, modification, and real-time adjustments, it has gradually replaced NC as computing costs declined. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed is "sliced" before the instructions (or the prog ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Very-low-drag Bullet

A very-low-drag bullet (VLD) is primarily a small arms ballistics development of the 1980s–1990s, driven by the design objective of bullets with higher degrees of accuracy and kinetic efficiency, especially at extended ranges. To achieve this, the projectile must minimize air resistance in flight. Usage has been greatest from military snipers and long-range target shooters, including F-class and benchrest competitors, but hunters have also benefited. Most VLD bullets are used in rifles. VLD bullets typically have a G1 ballistic coefficient greater than 0.5, although the threshold is undefined. Bullets with a lower drag coefficient decelerate less rapidly. A low drag coefficient flattens the projectile's trajectory and also markedly decreases the lateral drift caused by crosswinds. The higher velocity of bullets with low drag coefficients means they retain more kinetic energy. Development VLD bullets are long and heavy for their diameter, to achieve a high sectional density. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Naval Surface Warfare Center Crane Division

Naval Surface Warfare Center Crane Division (NSWC Crane Division) is the principal tenant command located at Naval Support Activity Crane (NSA Crane) in Indiana. NSA Crane is a United States Navy installation located approximately southwest of Bloomington, Indiana, Bloomington, Indiana, and predominantly located in Martin County, Indiana, Martin County, but small parts also extend into Greene County, Indiana, Greene and Lawrence County, Indiana, Lawrence counties. It was originally established in 1941 under the Bureau of Ordnance as the Naval Ammunition Depot for the production, testing, and storage of ordnance under the first supplemental Defense Appropriation Act. The base is named after William M. Crane. The base is the third largest naval installation in the world by geographic area and employs approximately 3,300 people. The closest community is the small town of Crane, Indiana, Crane, which lies adjacent to the northwest corner of the facility. Operations With an incre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Black Hills Ammunition

Black Hills Ammunition is an American ammunition and reloading supplies manufacturing company based in Rapid City, South Dakota. Description Black Hills is popular among Cowboy Action Shooters (see SASS, the Single Action Shooting Society) because they produce ammunition in a number of obsolete calibers, such as .44 Russian, .38 Long Colt, .44-40 and others. The exclusive distributor for Black Hills Ammunition in the United Kingdom The United Kingdom of Great Britain and Northern Ireland, commonly known as the United Kingdom (UK) or Britain, is a country in Northwestern Europe, off the coast of European mainland, the continental mainland. It comprises England, Scotlan ... is Edgar Brothers. References External links * Companies based in South Dakota Rapid City, South Dakota Ammunition manufacturers of the United States American companies established in 1981 1981 establishments in South Dakota {{US-manufacturing-company-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

M16 (rifle)

The M16 (officially Rifle, Caliber 5.56 mm, M16) is a family of assault rifles adapted from the ArmaLite AR-15 rifle for the United States military. The original M16 was a 5.56×45mm automatic rifle with a 20-round magazine. In 1964, the XM16E1 entered US military service as the M16 and in the following year was deployed for jungle warfare operations during the Vietnam War. In 1969, the M16A1 replaced the M14 rifle to become the US military's standard service rifle. The M16A1 incorporated numerous modifications including a bolt-assist ("forward-assist"), chrome-plated bore, protective reinforcement around the magazine release, and revised flash hider. In 1983, the US Marine Corps adopted the M16A2 rifle, and the US Army adopted it in 1986. The M16A2 fires the improved 5.56×45mm (M855/SS109) cartridge and has a newer adjustable rear sight, case deflector, heavy barrel, improved handguard, pistol grip, and buttstock, as well as a semi-auto and three-round burst fire ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

United States Marine Corps

The United States Marine Corps (USMC), also referred to as the United States Marines or simply the Marines, is the maritime land force service branch of the United States Department of Defense. It is responsible for conducting expeditionary and amphibious operations through combined arms, implementing its own infantry, artillery, aerial, and special operations forces. The U.S. Marine Corps is one of the six armed forces of the United States and one of the eight uniformed services of the United States. The Marine Corps has been part of the United States Department of the Navy since 30 June 1834 with its sister service, the United States Navy. The USMC operates installations on land and aboard sea-going amphibious warfare ships around the world. Additionally, several of the Marines' tactical aviation squadrons, primarily Marine Fighter Attack squadrons, are also embedded in Navy carrier air wings and operate from the aircraft carriers. The history of the Marine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

United States Navy

The United States Navy (USN) is the naval warfare, maritime military branch, service branch of the United States Department of Defense. It is the world's most powerful navy with the largest Displacement (ship), displacement, at 4.5 million tons in 2021. It has the world's largest aircraft carrier fleet, with List of aircraft carriers in service, eleven in service, one undergoing trials, two new carriers under construction, and six other carriers planned as of 2024. With 336,978 personnel on active duty and 101,583 in the Ready Reserve, the U.S. Navy is the third largest of the United States military service branches in terms of personnel. It has 299 deployable combat vessels and about 4,012 operational aircraft as of 18 July 2023. The U.S. Navy is one of six United States Armed Forces, armed forces of the United States and one of eight uniformed services of the United States. The United States Navy traces its origins to the Continental Navy, which was established during ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Sniper

A sniper is a military or paramilitary marksman who engages targets from positions of concealment or at distances exceeding the target's detection capabilities. Snipers generally have specialized training and are equipped with telescopic sights. Modern snipers use high-precision rifles and high-magnification optics. They often also serve as scouts/ observers feeding tactical information back to their units or command headquarters. In addition to long-range and high-grade marksmanship, military snipers are trained in a variety of special operation techniques: detection, stalking, target range estimation methods, camouflage, tracking, bushcraft, field craft, infiltration, special reconnaissance and observation, surveillance and target acquisition. Snipers need to have complete control of their bodies and senses in order to be effective. They also need to have the skill set to use data from their scope and monitors to adjust their aim to hit targets that are extremely f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |