|

T-slot Structural Framing

T-slot structural framing, sometimes known as aluminum extrusion, or 2020 extrusion when the cross-section is 20x20 mm, is a framing system consisting of lengths of square or rectangular extruded aluminum, typically 6105-T5 aluminium alloy, with a T-slot down the centerline of one or more sides. It is also known as 80/20 framing, after the company 80/20, Inc., one of the prominent T-slot framing brands, the name of which is based on the 80/20 or "Pareto" principle. While there is no published standard defining this framing system, manufacturers have settled into two categories of product comprising several series each that is generally intercompatible across manufacturers. There is a variation on T-slot profiles known as V-slot rails where V-slot wheels are slotted into the V-shaped channels of the framing for linear motion in a 3d printer or other CNC machine. Profiles T-slot framing is divided into metric and fractional (imperial) categories. The T-slot is always centered al ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

8020-Fractional-Profiles-1

8 (eight) is the natural number following 7 and preceding 9. In mathematics 8 is: * a composite number, its proper divisors being , , and . It is twice 4 or four times 2. * a power of two, being 2 (two cubed), and is the first number of the form , being an integer greater than 1. * the first number which is neither prime nor semiprime. * the base of the octal number system, which is mostly used with computers. In octal, one digit represents three bits. In modern computers, a byte is a grouping of eight bits, also called an octet. * a Fibonacci number, being plus . The next Fibonacci number is . 8 is the only positive Fibonacci number, aside from 1, that is a perfect cube. * the only nonzero perfect power that is one less than another perfect power, by Mihăilescu's Theorem. * the order of the smallest non-abelian group all of whose subgroups are normal. * the dimension of the octonions and is the highest possible dimension of a normed division algebra. * the first num ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extruded Aluminium Section X3

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal bars and tubes are also often drawn. Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). It can be done with hot or cold material. Commonly extruded materia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cross Section (geometry)

In geometry and science, a cross section is the non-empty intersection of a solid body in three-dimensional space with a plane, or the analog in higher-dimensional spaces. Cutting an object into slices creates many parallel cross-sections. The boundary of a cross-section in three-dimensional space that is parallel to two of the axes, that is, parallel to the plane determined by these axes, is sometimes referred to as a contour line; for example, if a plane cuts through mountains of a raised-relief map parallel to the ground, the result is a contour line in two-dimensional space showing points on the surface of the mountains of equal elevation. In technical drawing a cross-section, being a projection of an object onto a plane that intersects it, is a common tool used to depict the internal arrangement of a 3-dimensional object in two dimensions. It is traditionally crosshatched with the style of crosshatching often indicating the types of materials being used. With computed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal bars and tubes are also often drawn. Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). It can be done with hot or cold material. Commonly extruded materials ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

6105 Aluminium Alloy

6105 aluminium alloy is an alloy in the wrought aluminium-magnesium-silicon family (6000 or 6xxx series). It is one of the least common of the alloys in this series. While most wrought aluminium alloys are covered by multiple standards (from any mixture of ASTM, EN, ISO, and national standard bodies), 6105 is only dealt with in ''ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes''. It is formed by extrusion, and supplied in heat treated form. It can alternately referred to by the UNS designation A96105.Marks' Standard Handbook for Mechanical Engineers, 8th Ed., McGraw Hill, pp. 6-50 to 6-60 Chemical composition The alloy composition of 6105 aluminium is:6105 (A96105) Aluminum Retrieved on 2014-12-31. * |

80/20 Principle

The Pareto principle states that for many outcomes, roughly 80% of consequences come from 20% of causes (the "vital few"). Other names for this principle are the 80/20 rule, the law of the vital few, or the principle of factor sparsity. Management consultant Joseph M. Juran developed the concept in the context of quality control and improvement after reading the works of Italian sociologist and economist Vilfredo Pareto, who wrote about the 80/20 connection while teaching at the University of Lausanne. In his first work, ''Cours d'économie politique'', Pareto showed that approximately 80% of the land in the Kingdom of Italy was owned by 20% of the population. The Pareto principle is only tangentially related to the Pareto efficiency. Mathematically, the 80/20 rule is roughly described by a power law distribution (also known as a Pareto distribution) for a particular set of parameters. Many natural phenomena distribute according to power law statistics. It is an adage of busin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

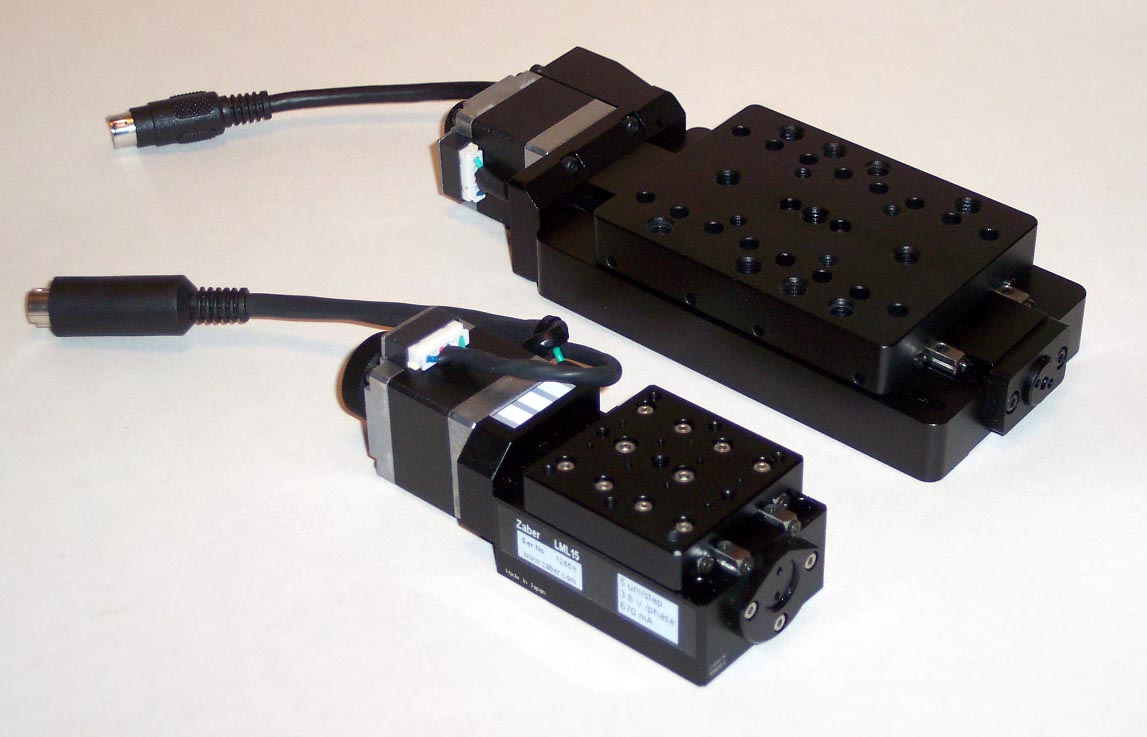

Linear Stage

A linear stage or translation stage is a component of a precise motion system used to restrict an object to a single axis of motion. The term linear slide is often used interchangeably with "linear stage", though technically "linear slide" refers to a linear motion bearing, which is only a component of a linear stage. All linear stages consist of a platform and a base, joined by some form of guide or linear bearing in such a way that the platform is restricted to linear motion with respect to the base. In common usage, the term linear stage may or may not also include the mechanism by which the position of the platform is controlled relative to the base. Principle of operation In three-dimensional space, an object may either rotate about, or translate along any of three axes. Thus the object is said to have six degrees of freedom (3 rotational and 3 translational). A linear stage exhibits only one degree of freedom (translation along one axis). In other words, linear stages opera ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

3d Printer

3D printing or additive manufacturing is the Manufacturing, construction of a three-dimensional object from a computer-aided design, CAD model or a digital 3D modeling, 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under Computer Numerical Control, computer control, with material being added together (such as plastics, liquids or powder grains being fused), typically layer by layer. In the 1980s, 3D printing techniques were considered suitable only for the production of functional or aesthetic prototypes, and a more appropriate term for it at the time was rapid prototyping. , the precision, repeatability, and material range of 3D printing have increased to the point that some 3D printing processes are considered viable as an industrial-production technology, whereby the term ''additive manufacturing'' can be used synonymously with ''3D printing''. One of the key advantages of 3D printing is the ability to produce very ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

CNC Machine

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

T-slot Nut

A T-slot nut is used with a threaded clamp to position and secure pieces being worked on in a workshop. The T-slot nut slides along a T-slot track, which is set in workbench or table for a router, drill press, or bandsaw. T-slot nuts are also used with T-slot structural framing to build a variety of industrial structures and machines. A T-slot bolt is generally stronger than a T-slot nut and hex-head cap screw. A heavy-duty T-slot nut with a M12 bolt is rated to support 10000 N (about 1 imperial ton at rest). and the T-slot nuts to fit into them comprised the first modular system developed for use in mechanical engineering in 1980 by item Industrietechnik. item Industrietechnik GmbH"timeline: 1980" The item aluminum framing system has since been expanded to include a variety of t-slot nuts that have been designed for specific applications. The item system is very similar to the "channel-and-groove design" used in some toys. File:CAD model of a T-Nut 1.png, CAD model ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strut Channel

Strut channel, often referred to colloquially by one of several manufacturer trade names, is a standardized formed structural system used in the construction and electrical industries for light structural support, often for supporting wiring, plumbing, or mechanical components such as air conditioning or ventilation systems. A strut is usually formed from a metal sheet, folded over into an open channel shape with inwards-curving lips to provide additional stiffness and as a location to mount interconnecting components. Increasingly, struts are being constructed from fiberglass, a highly corrosion-resistant material that's known for its lightweight strength and rigidity. Struts usually have holes of some sort in the base, to facilitate interconnection or fastening strut to underlying building structures. The main advantage of strut channels in construction is that there are many options available for rapidly and easily connecting lengths together and other items to the strut channel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |