|

Suzuki G Engine

The Suzuki G engine is a series of three- and four-cylinder internal combustion engines manufactured by Suzuki Motor Corporation for various automobiles, primarily based on the GM M platform, as well as many small trucks such as the Suzuki Samurai and Suzuki Vitara and their derivatives. Straight-threes G10/G10 Turbo The G10 (sometimes referred to as the "G10A" to set it apart from the later G10B) is a straight-three gasoline four-stroke engine using aluminum alloy for the block, cylinder head and pistons. It is equipped with either a carburetor or electronic fuel injection and was also offered as the G10T with an IHI RHB31/32 turbocharger and either MPFI or a carburetor. It has a single overhead camshaft driving six valves. Cylinder spacing is , as for the four-cylinder G13/G15/G16 engines. A bore and stroke give the engine a total of of displacement. It produces at 5100 rpm and at 3200 rpm with 9.5:1 compression in the carbureted model, at 5700 rpm and a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Suzuki Cultus

The Suzuki Cultus is a supermini car produced by the Japanese manufacturer Suzuki from 1983 to 2016. The nameplate is currently used as a rebadged second-generation Suzuki Celerio in Pakistan since 2017. It was first presented at the 25th Tokyo Motor Show, formally introduced to Japan in 1983 and ultimately sold in seven countries across three generations and marketed worldwide as the Suzuki Swift for the first two generations. An alliance formed in 1981 between General Motors, Suzuki and Isuzu allowed GM to market the Cultus as a captive import internationally under more than a dozen nameplates including the Geo Metro, Chevrolet Sprint, Pontiac Firefly and Holden Barina. It was also known as the M-car within GM. Offered across its lifespan in four body-style variations with engines from the Suzuki G engine family, the second generation Cultus still remained in production in Pakistan until late 2016. The Cultus family of vehicles has been marketed in Asia, Australia, Europe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

GM M Platform

The GM M platform was the designation used by General Motors for the platform that underpinned the first, second and third generation Suzuki Cultus and its offspring. The first generation of this platform had been designed by Suzuki for their 1983 Cultus, and adopted by Chevrolet with the introduction of the Sprint. The platforms of the second and third generations first appeared in 1989 and 1995 respectively. They were designed at GM's Technical Center in Warren, Michigan, USA. Suzuki designed all the engines, drivetrains and actual body. From 1985 through 1989, all models were imported from Suzuki's facilities in Hamamatsu, Japan. From 1990 on, some North American M-cars were produced at CAMI Automotive in Ingersoll, Ontario, Canada with the exception of the convertible and turbocharged models which were imported from Japan. The third generation M platform was only sold by Suzuki as the Suzuki Swift in North America as Suzuki decided to create their own Swift to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Control Unit

An engine control unit (ECU), also commonly called an engine control module (ECM), is a type of electronic control unit that controls a series of actuators on an internal combustion engine to ensure optimal engine performance. It does this by reading values from a multitude of sensors within the engine bay, interpreting the data using multidimensional performance maps (called lookup tables), and adjusting the engine actuators. Before ECUs, air–fuel mixture, ignition timing, and idle speed were mechanically set and dynamically controlled by mechanical and pneumatic means. If the ECU has control over the fuel lines, then it is referred to as an electronic engine management system (EEMS). The fuel injection system has the major role of controlling the engine's fuel supply. The whole mechanism of the EEMS is controlled by a stack of sensors and actuators. Workings Control of air–fuel ratio Most modern engines use some type of fuel injection to deliver fuel to the cylinders. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Lifters

A hydraulic tappet, also known as a hydraulic valve lifter or hydraulic lash adjuster, is a device for maintaining zero valve clearance in an internal combustion engine. Conventional solid valve lifters require regular adjusting to maintain a small clearance between the valve and its rocker or cam follower. This space prevents the parts from binding as they expand with the engine's heat, but can also lead to noisy operation and increased wear as the parts rattle against one another until they reach operating temperature. The hydraulic lifter was designed to compensate for this small tolerance, allowing the valve train to operate with zero clearance—leading to quieter operation, longer engine life, and eliminating the need for periodic adjustment of valve clearance. The hydraulic lifter, situated between the camshaft and each engine's valve, is a hollow steel cylinder encasing an internal piston. This piston is held at the outer limit of its travel with a strong spring. The l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Throttle-body Fuel Injection

Manifold injection is a mixture formation system for internal combustion engines with external mixture formation. It is commonly used in engines with spark ignition that use petrol as fuel, such as the Otto engine, and the Wankel engine. In a manifold-injected engine, the fuel is injected into the intake manifold, where it begins forming a combustible air-fuel mixture with the air. As soon as the intake valve opens, the piston starts sucking in the still forming mixture. Usually, this mixture is relatively homogeneous, and, at least in production engines for passenger cars, approximately stoichiometric; this means that there is an even distribution of fuel and air across the combustion chamber, and enough, but not more air present than what is required for the fuel's complete combustion. The injection timing and measuring of the fuel amount can be controlled either mechanically (by a fuel distributor), or electronically (by an engine control unit). Since the 1970s and 1980s, manifol ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Single Overhead Camshaft

An overhead camshaft (OHC) engine is a piston engine where the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block. ''Single overhead camshaft'' (SOHC) engines have one camshaft per bank of cylinders. ''Dual overhead camshaft'' (DOHC, also known as "twin-cam".) engines have two camshafts per bank. The first production car to use a DOHC engine was built in 1910. Use of DOHC engines slowly increased from the 1940s, leading to many automobiles by the early 2000s using DOHC engines. Design In an OHC engine, the camshaft is located at the top of the engine, above the combustion chamber. This contrasts the earlier overhead valve engine (OHV) and flathead engine configurations, where the camshaft is located down in the engine block. The valves in both OHC and OHV engines are located above the combustion chamber; however an OHV en ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a supercharger is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |

IHI Corporation

, formerly known as , is a Japanese engineering corporation headquartered in Tokyo, Japan that produces and offers ships, space launch vehicles, aircraft engines, marine diesel engines, gas turbines, gas engines, railway systems, turbochargers for automobiles, plant engineering, industrial machinery, power station boilers and other facilities, suspension bridges and other structures. IHI is listed on the Tokyo Stock Exchange Section 1. History * 1853 – establishment of Ishikawajima Shipyard in the Chuo district of Tokyo. * 1854 - 1856: construction of the Japanese warship Asahi Maru at Ishikawajima shipyard. * 1889 – incorporation of Ishikawajima Shipyard as Ishikawajima Shipbuilding & Engineering Co., Ltd. * 1907 – establishment of Harima Dock Co., Ltd. * 1929 – spinoff of Harima's automobile section as Ishikawajima Automotive Works (later Isuzu through a series of mergers) * 1960 – establishment of Ishikawajima-Harima Heavy Industries Co., Ltd. through a merger o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electronic Fuel Injection

Manifold injection is a mixture formation system for internal combustion engines with external mixture formation. It is commonly used in engines with spark ignition that use petrol as fuel, such as the Otto engine, and the Wankel engine. In a manifold-injected engine, the fuel is injected into the intake manifold, where it begins forming a combustible air-fuel mixture with the air. As soon as the intake valve opens, the piston starts sucking in the still forming mixture. Usually, this mixture is relatively homogeneous, and, at least in production engines for passenger cars, approximately stoichiometric; this means that there is an even distribution of fuel and air across the combustion chamber, and enough, but not more air present than what is required for the fuel's complete combustion. The injection timing and measuring of the fuel amount can be controlled either mechanically (by a fuel distributor), or electronically (by an engine control unit). Since the 1970s and 1980s, manifol ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

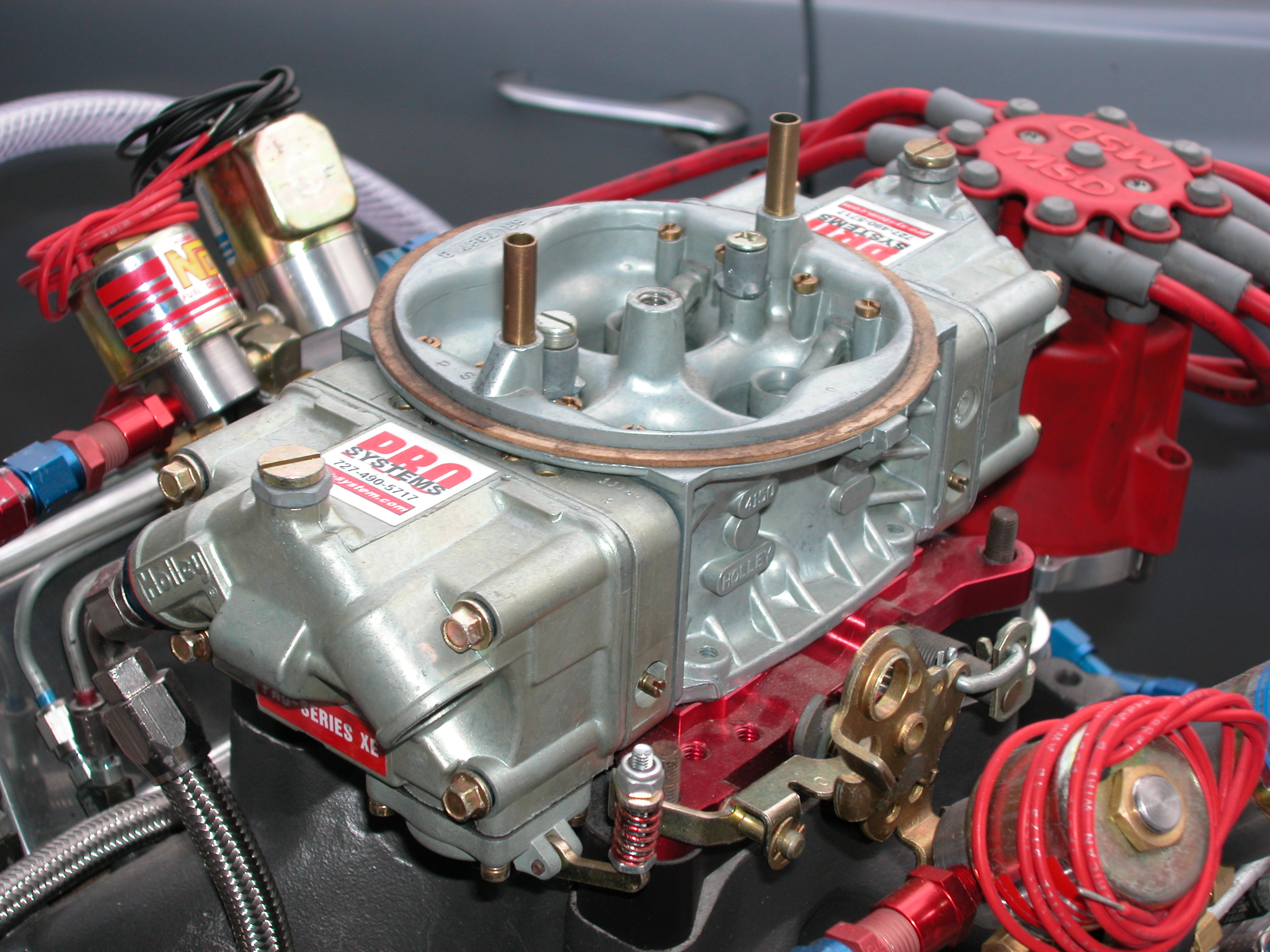

Carburetor

A carburetor (also spelled carburettor) is a device used by an internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the venturi tube in the main metering circuit, however various other components are also used to provide extra fuel or air in specific circumstances. Since the 1990s, carburetors have been largely replaced by fuel injection for cars and trucks, however carburetors are still used by some small engines (e.g. lawnmowers, generators and concrete mixers) and motorcycles. Diesel engines have always used fuel injection instead of carburetors. Etymology The name "carburetor" is derived from the verb ''carburet'', which means "to combine with carbon," or in particular, "to enrich a gas by combining it with carbon or hydrocarbons." Thus a carburetor mixes intake air with hydrocarbon-based fuel, such as petrol or autogas (LPG). The name is spelled "carburetor" in American English ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Head

In an internal combustion engine, the cylinder head (often abbreviated to simply "head") sits above the cylinders and forms the roof of the combustion chamber. In sidevalve engines, the head is a simple sheet of metal; whereas in more modern overhead valve and overhead camshaft engines, the cylinder head is a more complicated block often containing inlet and exhaust passages, coolant passages, valves, camshafts, spark plugs and fuel injectors. Most straight engines have a single cylinder head shared by all of the cylinders and most V engines have two cylinder heads (one per bank of cylinders). Design A summary of engine designs is shown below, in chronological order for automobile usage. Sidevalve engines In a flathead (''sidevalve'') engine, all of the valvetrain components are contained within the block, therefore the head is usually a simple sheet of metal bolted to the top of the engine block. Sidevalve engines were once universal in automobiles but are now lar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Four-stroke Engine

A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed: #Intake: Also known as induction or suction. This stroke of the piston begins at top dead center (T.D.C.) and ends at bottom dead center (B.D.C.). In this stroke the intake valve must be in the open position while the piston pulls an air-fuel mixture into the cylinder by producing vacuum pressure into the cylinder through its downward motion. The piston is moving down as air is being sucked in by the downward motion against the piston. #Compression: This stroke begins at B.D.C, or just at the end of the suction stroke, and ends at T.D.C. In this stroke the piston compresses the air-fuel mixture in preparation for ignition during the power stroke (below). Both the intake and exhaust valves are close ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |