|

Structural Pipe Fitting

A structural pipe fitting, also known as a slip on pipe fitting, clamp or pipe clamp is used to build structures such as handrails, guardrails, and other types of pipe or tubular structure. They can also be used to build furniture and theatrical riggings. The fittings slip on the pipe and are usually locked down with a set screw. The set screw can then be tightened with a simple hex wrench. Because of the modular design of standard fittings, assembly is easy, only simple hand tools are required, and risks from welding a structure are eliminated. Other advantages of using structural pipe fittings are easy installation and reconfigurable design. Since there are no permanent welds in the structure, the set screws of thfittings can simply be loosened allowing them to be repositioned. The project can be disassembled and stored if needed, or even taken apart with fittings and pipe recycled into a new project. Fittings used for strong structures are galvanised Galvanization or gal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

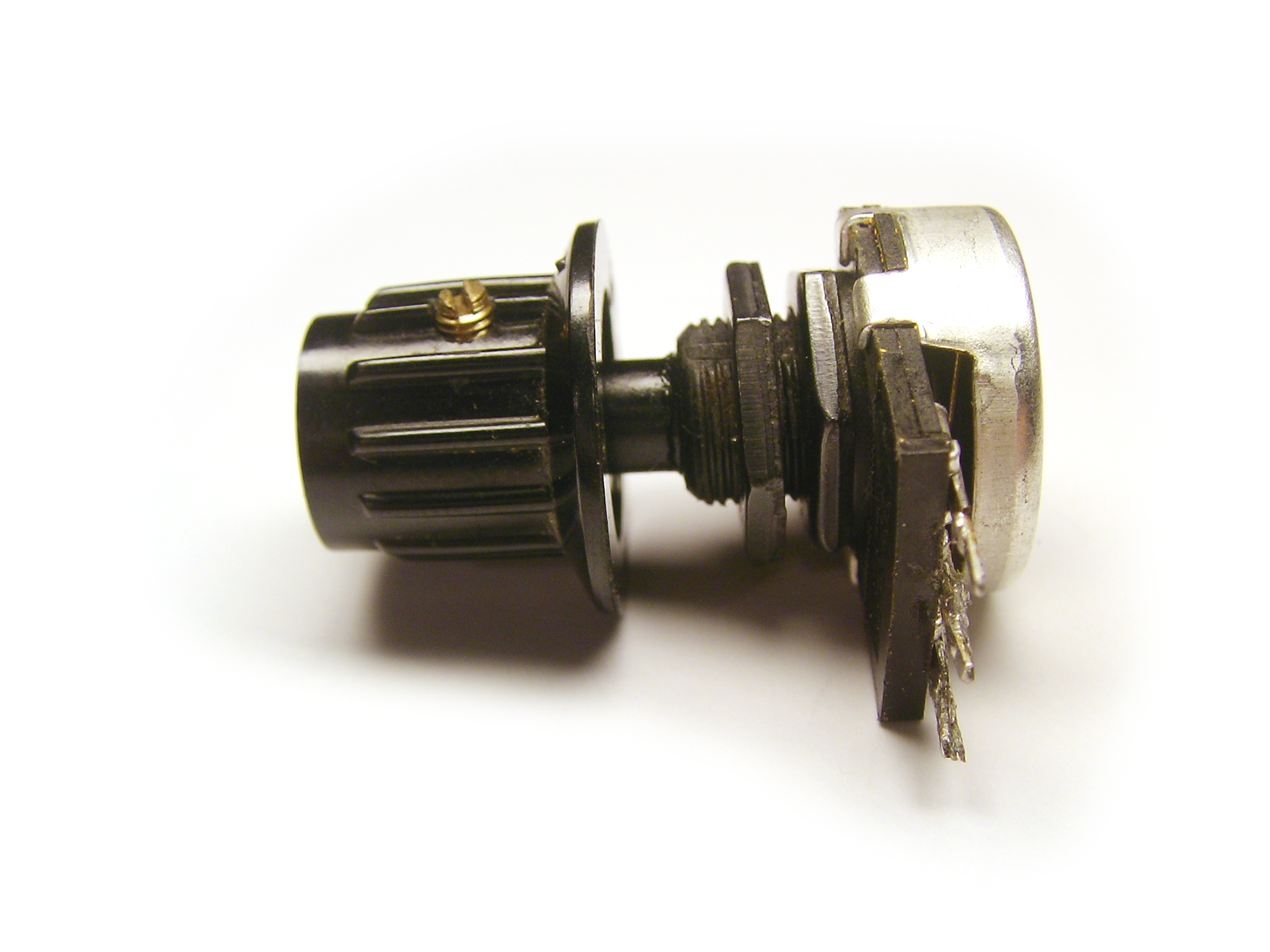

Set Screw

In American English, a set screw is a screw that is used to secure an object, by pressure and/or friction, within or against another object, such as fixing a pulley or gear to a shaft. A set screw is normally used without a nut (which distinguishes it from a bolt), being screwed instead in a threaded hole drilled in only one of the two objects to be secured. A set screw is often headless and threaded along its entire length, so that it will sit entirely inside that hole; in which case it may be called a grub screw or blind screw. Once fully and firmly screwed into the first object, the projecting tip of the set screw presses hard against the second object, acting like a clamp. The second object may have a machined detent (recess) to ensure that it cannot slide under the tip of the screw. On a shaft, this may be simply a flattened area. A set screw may have any type of drive, such as hex or square head, slot, or recessed --- cross (Phillips), hex (Allen), star (Torx), or sq ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

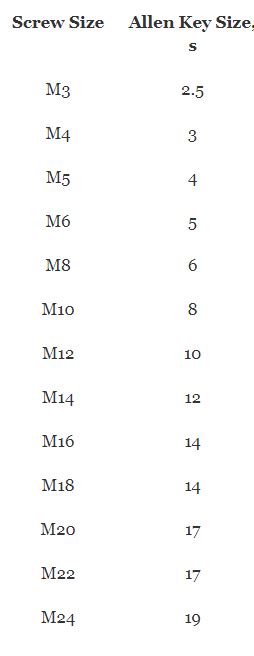

Hex Wrench

Hex keys of various sizes Socket head screws of various sizes A hex key (also, hex wrench, Allen key and Allen wrench) is a simple driver for bolts or screws that have heads with ''internal'' hexagonal recesses (sockets). Hex keys are formed from a single piece of hard hexagonal steel rod, having blunt ends that fit snugly into similarly-shaped screw sockets. The rods are bent to 90º, forming two arms of unequal length resembling an "L". The tool is usually held and twisted by its long arm, creating a relatively large torque at the tip of the short arm; it can also be held by its short arm to access screws in difficult-to-reach locations and to turn screws faster at the expense of torque. Hex keys are designated with a socket size and are manufactured with tight tolerances. As such, they are commonly sold in kits that include a variety of sizes. Key length typically increases with size, but not necessarily proportionally so. Variants on this design have the short end inse ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Modular Design

Modular design, or modularity in design, is a design principle that subdivides a system into smaller parts called ''modules'' (such as modular process skids), which can be independently created, modified, replaced, or exchanged with other modules or between different systems. Overview A modular design can be characterized by functional partitioning into discrete scalable and reusable modules, rigorous use of well-defined modular interfaces, and making use of industry standards for interfaces. In this context modularity is at the component level, and has a single dimension, component slottability. A modular system with this limited modularity is generally known as a platform system that uses modular components. Examples are car platforms or the USB port in computer engineering platforms. In design theory this is distinct from a modular system which has higher dimensional modularity and degrees of freedom. A modular system design has no distinct lifetime and exhibits flexibility ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piping Fitting

A fitting or adapter is used in pipe systems to connect straight sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating (or measuring) fluid flow. These fittings are used in plumbing to manipulate the conveyance of water, gas, or liquid waste in domestic or commercial environments, within a system of pipes or tubes. Fittings (especially uncommon types) require money, time, materials, and tools to install and are an important part of piping and plumbing systems. Valves are technically fittings, but are usually discussed separately. Standards Standard codes are followed when designing (or manufacturing) a piping system. Organizations which promulgate piping standards include: * ASME: American Society of Mechanical Engineers ** A112.19.1 Enameled cast-iron and steel plumbing fixtures standards ** A112.19.2 Ceramic plumbing fixtures standard * ASTM International: American Society for Testing and Materials * API: American Petr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Galvanised

Galvanization or galvanizing ( also spelled galvanisation or galvanising) is the process of applying a protective zinc coating to steel or iron, to prevent rusting. The most common method is hot-dip galvanizing, in which the parts are submerged in a bath of hot, molten zinc. Protective action The zinc coating, when intact, prevents corrosive substances from reaching the underlying iron. Additional electroplating such as a chromate conversion coating may be applied to provide further surface passivation to the substrate material. History and etymology The earliest known example of galvanized iron was encountered by Europeans on 17th-century Indian armour in the Royal Armouries Museum collection. The term "galvanized" continues to be used metaphorically of any stimulus which results in activity by a person or group of people. In modern usage, the term "galvanizing" has largely come to be associated with zinc coatings, to the exclusion of other metals. Galvanic paint, a prec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

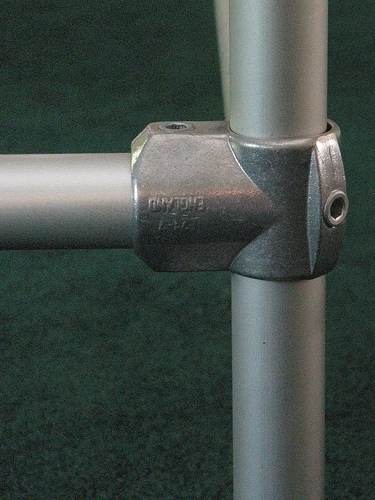

Kee Klamp

A Kee Klamp is a structural pipe fitting commonly used in the construction of handrails and barriers. Fabricated installations comprise the fittings and separate tubing components, which can be sized on site. The system was devised in 1934 and is made by a subsidiary of KIG Holdings. The fittings are mostly supplied to third parties for sale to fabricators, with a small proportion of sales being made internally to specialist divisions of the company. History The system was developed in 1934 by George H. Gascoigne and his colleagues in Reading, England for making cows' milking stalls. It was advertised to industrial chemists in 1944, marketed in the UK in the 1950s as a cattle control system, and used for storage systems in factories in the 1960s. By 1980 it was available in Canada, as noted by the Canadian Institute of Mining and Metallurgy. Components The system comprises unthreaded cast iron or aluminium structural tubing and slip-on structural pipe fittings. The galva ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |