|

Slickline

{{more citations needed, date=April 2012 Slickline refers to a single strand wire which is used to run a variety of tools down into the wellbore for several purposes. It is used during well drilling operations in the oil and gas industry. In general, it can also describe a niche of the industry that involves using a slickline truck or doing a slickline job. Slickline looks like a long, smooth, unbraided wire, often shiny, silver/chrome in appearance. It comes in varying lengths, according to the depth of wells in the area it is used (it can be ordered to specification) up to 35,000 feet in length. It is used to lower and raise downhole tools used in oil and gas well maintenance to the appropriate depth of the drilled well. In use and appearance it is connected by a drum as it is spooled off the back of the slickline truck to the wireline sheave, a round wheel grooved and sized to accept a specified line and positioned to redirect the line to another sheave that will allow the sl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slickline Tubing Broach

{{more citations needed, date=April 2012 Slickline refers to a single strand wire which is used to run a variety of tools down into the wellbore for several purposes. It is used during well drilling operations in the oil and gas industry. In general, it can also describe a niche of the industry that involves using a slickline truck or doing a slickline job. Slickline looks like a long, smooth, unbraided wire, often shiny, silver/chrome in appearance. It comes in varying lengths, according to the depth of wells in the area it is used (it can be ordered to specification) up to 35,000 feet in length. It is used to lower and raise downhole tools used in oil and gas well maintenance to the appropriate depth of the drilled well. In use and appearance it is connected by a drum as it is spooled off the back of the slickline truck to the wireline sheave, a round wheel grooved and sized to accept a specified line and positioned to redirect the line to another sheave that will allow the sl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Well Drilling

Well drilling is the process of drilling a hole in the ground for the extraction of a natural resource such as ground water, brine, natural gas, or petroleum, for the injection of a fluid from surface to a subsurface reservoir or for subsurface formations evaluation or monitoring. Drilling for the exploration of the nature of the material underground (for instance in search of metallic ore) is best described as '' borehole'' drilling. The earliest wells were water wells, shallow pits dug by hand in regions where the water table approached the surface, usually with masonry or wooden walls lining the interior to prevent collapse. Modern drilling techniques utilize long drill shafts, producing holes much narrower and deeper than could be produced by digging. Well drilling can be done either manually or mechanically and the nature of required equipment varies from extremely simple and cheap to very sophisticated. Managed Pressure Drilling (MPD) is defined by the Internation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheave

A sheave () or pulley wheel is a grooved wheel often used for holding a belt, wire rope, or rope and incorporated into a pulley A pulley is a wheel on an axle or shaft that is designed to support movement and change of direction of a taut cable or belt, or transfer of power between the shaft and cable or belt. In the case of a pulley supported by a frame or shell that .... The sheave spins on an axle or bearing inside the frame of the pulley. This allows the wire or rope to move freely, minimizing friction and wear on the cable. Sheaves can be used to redirect a cable or rope, lift loads, and transmit power. The words ''sheave'' and ''pulley'' are sometimes used interchangeably. Adjustable pulley A sheave can also refer to a pulley which has an adjustable operating diameter for use with a mechanical belt. This is accomplished by constructing the pulley out of several pieces. The two main "halves" of the pulley can be moved closer together or farther apart, thus alte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Downhole Safety Valve

A downhole safety valve refers to a component on an oil and gas well, which acts as a failsafe to prevent the uncontrolled release of reservoir fluids in the event of a worst-case-scenario surface disaster. It is almost always installed as a vital component on the completion. Operation These valves are commonly uni-directional flapper valves which open downwards such that the flow of wellbore fluids tries to push it shut, while pressure from the surface pushes it open. This means that when closed, it will isolate the reservoir fluids from the surface. Most downhole safety valves are controlled hydraulically from the surface, meaning they are opened using a hydraulic connection linked directly to a well control panel. When hydraulic pressure is applied down a control line, the hydraulic pressure forces a sleeve within the valve to slide downwards. This movement compresses a large spring and pushes the flapper downwards to open the valve. When hydraulic pressure is removed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Lift

Gas lift or bubble pumps use the artificial lift technique of raising a fluid such as water or oil by introducing bubbles of compressed air, water vapor or other vaporous bubbles into the outlet tube. This has the effect of reducing the hydrostatic pressure in the outlet tube vs. the hydrostatic pressure at the inlet side of the tube. Devices using this type of lift mechanism: * Coffee percolators and electric drip coffeemakers use vaporized water to lift hot water *Airlift pumps uses compressed air to lift water *Pulser pumps use a subterranean chamber of air for an airlift pump * Suction dredges use an airlift pump to vacuum mud, sand and debris *Mist lift pumps uses vaporized water to lift seawater in Ocean thermal energy conversion Petroleum industry uses In the United States, gas lift is used in 10% of the oil wells that have insufficient reservoir pressure to produce the well. In the petroleum industry, the process involves injecting gas through the tubing-casing annulu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Fluid

A hydraulic fluid or hydraulic liquid is the medium by which power is transferred in hydraulic machinery. Common hydraulic fluids are based on mineral oil or water. Examples of equipment that might use hydraulic fluids are excavators and backhoes, hydraulic brakes, power steering systems, automatic transmissions, garbage trucks, aircraft flight control systems, lifts, and industrial machinery. Hydraulic systems like the ones mentioned above will work most efficiently if the hydraulic fluid used has zero compressibility. Functions and properties The primary function of a hydraulic fluid is to convey power. In use, however, there are other important functions of hydraulic fluid such as protection of the hydraulic machine components. The table below lists the major functions of a hydraulic fluid and the properties of a fluid that affect its ability to perform that function: Composition Base stock The original hydraulics fluid, dating back to the time of ancient Eg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

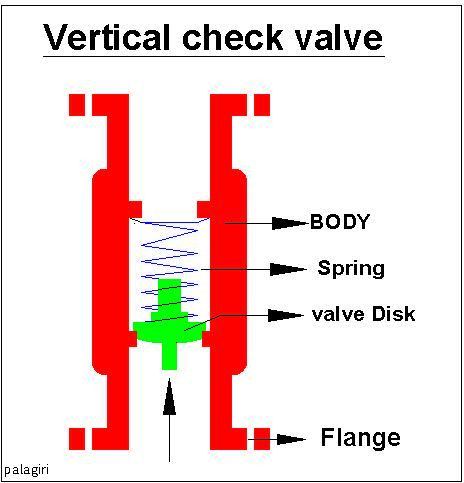

Non-return Valve

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction. Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. Check valves are often part of common household items. Although they are available in a wide range of sizes and costs, check valves generally are very small, simple, and inexpensive. Check valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. The bodies (external shells) of most check valves are made of plastic or metal. An important concept in check valves is the cracking pressure which is the minimum differential upstream pressure between inlet and outlet at which the valve will operate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drilling Technology

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minute. This forces the cutting edge against the work-piece, cutting off chips (swarf) from the hole as it is drilled. In rock drilling, the hole is usually not made through a circular cutting motion, though the bit is usually rotated. Instead, the hole is usually made by hammering a drill bit into the hole with quickly repeated short movements. The hammering action can be performed from outside the hole ( top-hammer drill) or within the hole ( down-the-hole drill, DTH). Drills used for horizontal drilling are called drifter drills. In rare cases, specially-shaped bits are used to cut holes of non-circular cross-section; a square cross-section is possible. Process Drilled holes are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |