|

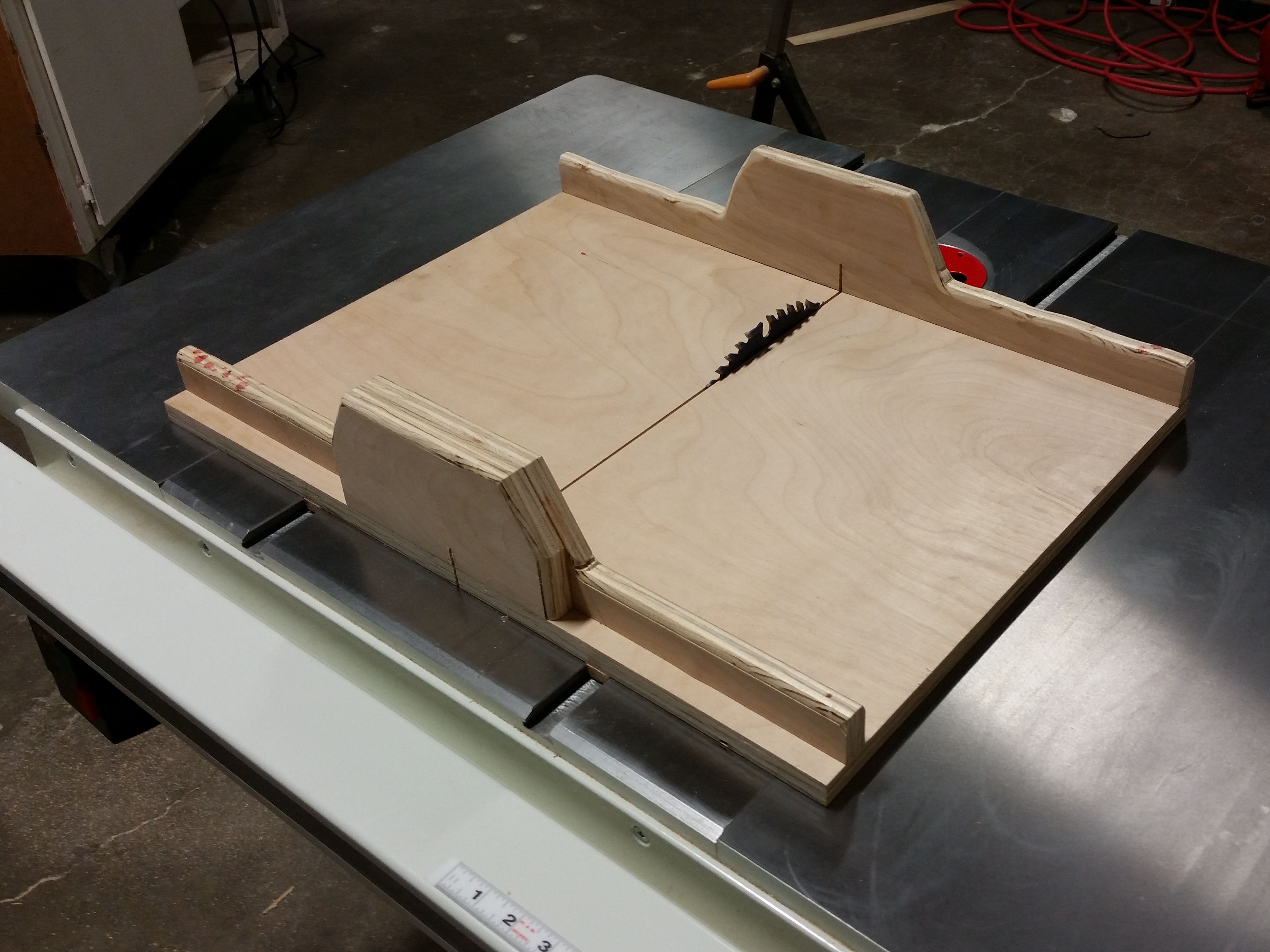

Shooting Board

A shooting board is a jig for woodworking which is used in combination with a hand plane to trim and square up the edges and ends of boards. It would typically be used on a workbench. A plank or board with edges planed flat is called a shot edge board. There are two specific purposes to which shooting boards are applied: jointing and end grain trimming. The design of the shooting board remains fundamentally the same in both cases but the length of the board will vary - with the boards used for jointing being much longer than those intended for end grain trimming. A shooting board consists of a flat board, the ''base'', with a stop at one end, similar to a bench hook, on which the board to be planed is rested. The stop prevents the board from sliding as it is planed. Parallel to the base and slightly lower is a secondary surface, the ''fence'', which may be a separate board, or may be a rabbet cut into the base. The difference in height between the base and the fence is to al ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bench Hook

A bench hook is a workbench appliance used in woodworking to hold a workpiece in place while crosscutting with a hand saw. A bench hook is a simple method used to improve accuracy and safety. Construction Bench hooks are simple in construction and though they can be purchased, they are typically made by the woodworker from offcuts and scraps of timber or sheet goods (such as plywood). The most common type of bench hook is made from three pieces of wood joined together: * The ''bed'', being anywhere from wide and long depending on preference. The workpiece sits atop the bed, and the bed protects the workbench from the saw. * The first stop, also called the fence, is fixed across the top of the bed. Usually this stop doesn't span the full width of the bed, so that the end of the stop can be used as a guide while sawing. This way the saw cuts into the bench hook and not the workbench. * The other stop, or the ''hook'', being as long as the bed is wide, it is fixed into the und ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

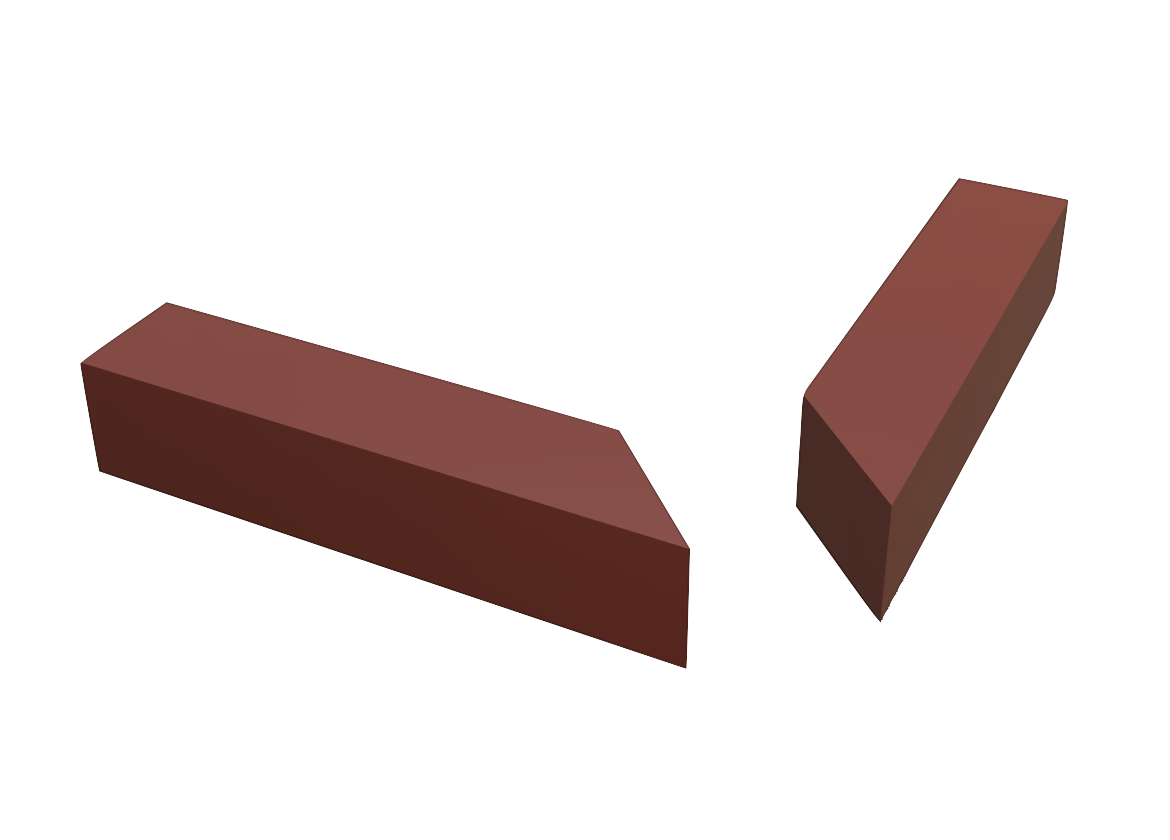

Mitre Joint

A mitre joint (often miter in American English) is a joint made by cutting each of two parts to be joined, across the main surface, usually at a 45° angle, to form a corner, usually to form a 90° angle, though it can comprise any angle greater than 0 degrees. It is called beveling when the angled cut is done on the side, although the resulting joint is still a mitre joint. For woodworking, a disadvantage of a mitre joint is its Strength of materials, weakness, but it can be strengthened with a spline (a thin wafer of wood inserted into a slot, usually arranged with the long grain of the spline across the short grain of the frame timber). There are two common variations of a splined mitre joint, one where the spline is long and runs the length of the mating surfaces and another where the spline is perpendicular to the joined edges. Common applications include picture frames, Pipe (fluid conveyance), pipes, and moulding (decorative), molding. Non-perpendicular joints For mitr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

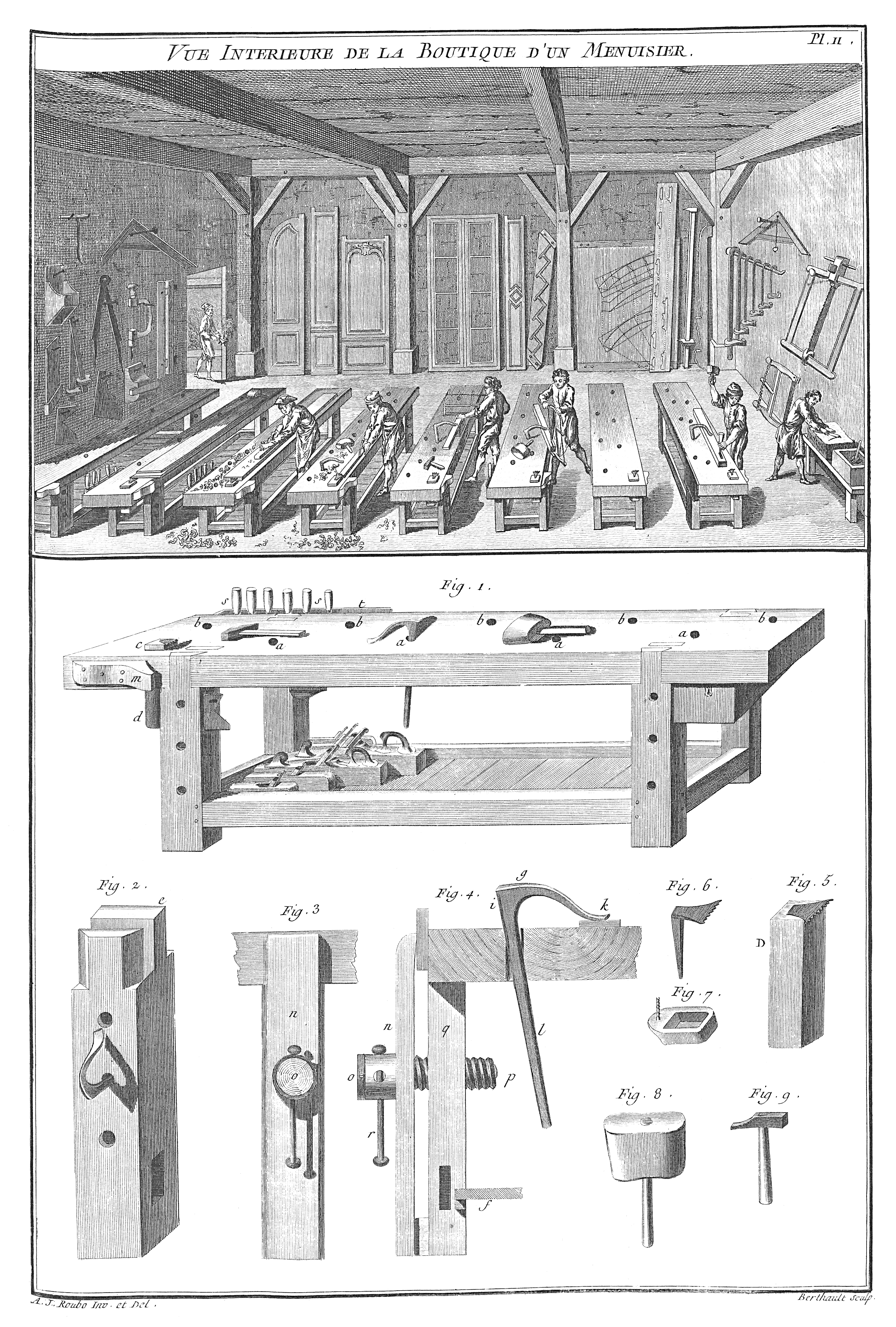

Workshop

Beginning with the Industrial Revolution era, a workshop may be a room, rooms or building which provides both the area and tools (or machinery) that may be required for the manufacture or repair of manufactured goods. Workshops were the only places of production until the advent of industrialization and the development of larger factories. In the 20th and 21st century, many Western homes contained a workshop in either the garage, basement, or an external shed. Home workshops typically contain a workbench, hand tools, power tools, and other hardware. Along with the practical application of repairing goods, workshops are often used to tinker and make prototypes. Some workshops focus exclusively on automotive repair or restoration although there are a variety of workshops in existence today. Woodworking, metalworking, electronics, and other types of electronic prototyping workshops are among the most common. Backshop In some repair industries, such as locomotives and aircraf ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sharpening

Sharpening is the process of creating or refining the edge joining two non-coplanar faces into a converging apex, thereby creating an edge of appropriate shape on a tool or implement designed for cutting. Sharpening is done by removing material on an implement with an abrasive substance harder than the material of the implement, followed sometimes by processes to polish/hone the sharp surface to increase smoothness. Tools and materials There are many ways of sharpening tools. Malleable metal surfaces such as bronze, iron and mild steel may be formed by beating or peening a flat surface into a sharp edge. This process also causes work hardening. An abrasive material may be rubbed against the cutting edge to be sharpened. The most traditional abrasive material is a natural stone such as sandstone or granite. Modern synthetic grinding wheels and flat sharpening stones can be manufactured in precise grades of abrasiveness according to the intended process. A sharp edge may be ' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworker

Woodworking is the skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, joinery, carpentry, and woodturning. History Along with stone, clay and animal parts, wood was one of the first materials worked by early humans. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. The development of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials. Among early finds of wooden tools are the worked sticks from Kalambo Falls, Clacton-on-Sea and Lehringen. The spears from Schöningen (Germany) provide some of the first examples of wooden hunting gear. Flint tools were used for carving. Since Neolithic times, carved wooden vessels are known, for example, from the Linear Pottery culture wells at Kückhofen and Eythra. Examples of Bronze Age wood-carving include tree trunks worked into coffins from northern Germany ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rabbet

A rabbet (American English) or rebate (British English) is a recess or groove cut into the edge of a piece of machinable material, usually wood. When viewed in cross-section, a rabbet is two-sided and open to the edge or end of the surface into which it is cut. An example of the use of a rabbet is in a glazing bar where it makes provision for the insertion of the pane of glass and putty. It may also accommodate the edge of the back panel of a cabinet. It is also used in door and casement window jambs, and for shiplap planking. A rabbet can be used to form a joint with another piece of wood (often containing a dado). Rabbet joints are easy to construct and have good appeal to them. They are simple to use in carpentry based work but can be doubtful when it comes to the strength of the joint. Nails and screws can be added to help increase the overall strength. Etymology The word ''rabbet'' is from Old French ''rabbat'', "a recess into a wall", and ''rabattre'' "to beat down ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fence (woodworking)

A fence is a part of many woodworking tools, they are typically used to guide or secure a workpiece while it is being sawn, planed, routed or marked. Fences play an important role for both accuracy and safety. Fences are usually straight and vertical, and made from metal, wood or plastic. Most fences either remain static with the workpiece guided along it, or are moved relative to the blade. Auxiliary and a sacrificial fences An auxiliary or sacrificial fence is a fence made of a material not liable to damage the blade – such as wood or plastic – and is usually attached to an existing fence. Such a fence may be used for situations where it is desirable or necessary for the fence to be in contact with, or particularly close to, the blade. They may also be used for attaching accessories to the fence, such as stop blocks and featherboards. Zero-clearance sacrificial fences can also be used to make cleaner cuts. Such fences may be considered sacrificial as they will be cut into ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

End Grain

Wood grain is the longitudinal arrangement of wood fibers or the pattern resulting from such an arrangement. Definition and meanings R. Bruce Hoadley wrote that ''grain'' is a "confusingly versatile term" with numerous different uses, including the direction of the wood cells (e.g., ''straight grain'', ''spiral grain''), surface appearance or figure, growth-ring placement (e.g., ''vertical grain''), plane of the cut (e.g., ''end grain''), rate of growth (e.g., ''narrow grain''), and relative cell size (e.g., ''open grain'').Hoadley, R. Bruce. "Glossary." ''Understanding Wood: A Craftsman's Guide to Wood Technology''. Newtown, Conn.: Taunton, 1980. 265. Print. Physical aspects Perhaps the most important physical aspect of wood grain in woodworking is the grain direction or slope (e.g. against the grain). The two basic categories of grain are straight and cross grain. Straight grain runs parallel to the longitudinal axis of the piece. Cross grain deviates from the longitudinal a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Edge Jointing

Edge jointing or just jointing is the process of making the edge of a wooden board straight and true in preparation for subsequent operations, often ultimately leading to joining two or more components together. Traditionally, jointing was performed using a jointer plane. Modern techniques include the use of a jointer machine, a hand held router and straight edge, or a table-mounted router. Although the process derives its name from the primary task of straightening an edge prior to joining, the term ''jointing'' is used whenever this process is performed, regardless of the application. Normally, the desired outcome of jointing is an edge which is straight along its length and perpendicular to the face of the board. However, there is a technique often used when gluing up panels, referred to as a ''sprung joint''. In this technique, the desired outcome is an edge which is slightly concave along its length. When two such edges are brought together and clamped, the sprung edges cr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Workbench

A workbench is a sturdy table at which manual work is done. They range from simple flat surfaces to very complex designs that may be considered tools in themselves. Workbenches vary in size from tiny jewellers benches to the huge benches used by staircase makers. Almost all workbenches are rectangular in shape, often using the surface, corners and edges as flat/square and dimension standards. Design is as varied as the type of work for which the benches are used but most share these attributes: * A comfortable height for working with provisions for seated or standing work * A way to fix the workpiece to the surface so that it may be worked with both hands * Provisions for mounting, storing and accessing tools Workbenches are made from many different materials including metal, wood, stone, and composites depending on the needs of the work. Types Workbench types may be divided according to the particular work they are designed to accommodate: ;Multi-purpose/portable: These benc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |