|

Saviem SM

The Saviem SM was a range of medium trucks produced by the French manufacturer Saviem between 1967 and 1975. History At the end of 1967, as part of an extended partnership with the German MAN, Saviem introduced the SM (Saviem-MAN) ranges. They were made up of the namesake SM medium truck range using the 812 cab, derived from the cab used for the SG range ( Super Galion and Super Goélette), and the heavier SM Europe range using the Europe/Espace cab. The commercial versions of the SM were discontinued in 1975, although versions for military use were still produced after that year. Technical details Variants The SM range line-up included the SM5 (8.7-tonne GVW), the SM6 (9-tonne GVW), the SM7 (10.95-tonne GVW) and the SM8 (12.3-tonne GVW). Engines All the SM range (except for the SM5) initially used the 597 engine manufactured at Saviem's Limoges plant, and later its evolutions: the 797 and the 798. The 597 was introduced in 1967, and it was also used for trucks of the MA ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Saviem

The Société Anonyme de Véhicules Industriels et d'Équipements Mécaniques (), commonly known by the acronym Saviem (), was a French manufacturer of trucks and buses/coaches part of the Renault group, headquartered in Suresnes, Île-de-France. The company was established in 1955 by merging Renault heavy vehicle operations with Somua and Latil and disappeared in 1978 when was merged with former rival Berliet to form Renault Véhicules Industriels. The company initially had various factories for vehicle production around France (mainly at the Paris area) which came from its predecessors and Chausson, but it soon centred assembly on Blainville-sur-Orne (trucks) and Annonay (buses and coaches). Saviem formed partnerships with other manufacturers, leading to technology-sharing agreements. History Early years At the end of 1946, Renault abandoned the production of heavy trucks in view of its financial troubles, and the company lost the position of France's market leader which ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

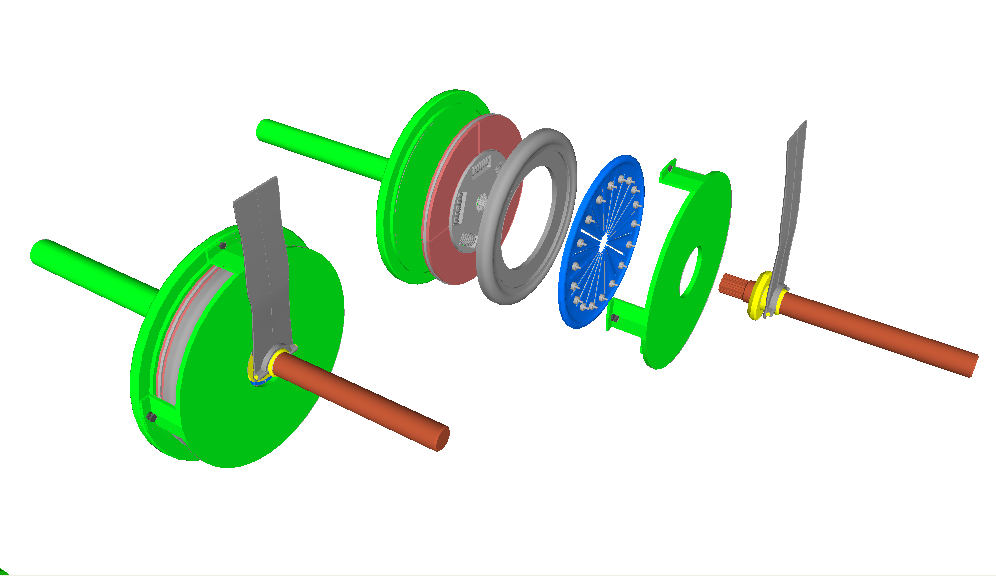

Saviem SM7 Pic4 - Cardan

The Société Anonyme de Véhicules Industriels et d'Équipements Mécaniques (), commonly known by the acronym Saviem (), was a French manufacturer of trucks and buses/coaches part of the Renault group, headquartered in Suresnes, Île-de-France. The company was established in 1955 by merging Renault heavy vehicle operations with Somua and Latil and disappeared in 1978 when was merged with former rival Berliet to form Renault Véhicules Industriels. The company initially had various factories for vehicle production around France (mainly at the Paris area) which came from its predecessors and Chausson, but it soon centred assembly on Blainville-sur-Orne (trucks) and Annonay (buses and coaches). Saviem formed partnerships with other manufacturers, leading to technology-sharing agreements. History Early years At the end of 1946, Renault abandoned the production of heavy trucks in view of its financial troubles, and the company lost the position of France's market leader ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air Brake (road Vehicle)

An air brake or, more formally, a compressed-air-brake system, is a type of friction brake for vehicles in which compressed air pressing on a piston is used to apply the pressure to the brake pad or brake shoe needed to stop the vehicle. Air brakes are used in large heavy vehicles, particularly those having multiple trailers which must be linked into the brake system, such as trucks, buses, trailers, and semi-trailers, in addition to their use in railroad trains. George Westinghouse first developed air brakes for use in railway service. He patented a safer air brake on March 5, 1872. Westinghouse made numerous alterations to improve his air pressured brake invention, which led to various forms of the automatic brake. In the early 20th century, after its advantages were proven in railway use, it was adopted by manufacturers of trucks and heavy road vehicles. Design and function Air brakes are typically used on heavy trucks and buses. Typical operating pressure is approximatel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Brake

A hydraulic brake is an arrangement of braking mechanism which uses brake fluid, typically containing glycol ethers or diethylene glycol, to transfer pressure from the controlling mechanism to the braking mechanism. History During 1904, Frederick George Heath (Heath Hydraulic Brake Co., Ltd.), Redditch, England devised and fitted a hydraulic (water/glycerine) brake system to a cycle using a handlebar lever and piston. He obtained patent GB190403651A for “Improvements in hydraulic actuated brakes for cycles and motors”, as well as subsequently for improved flexible rubber hydraulic pipes. In 1908, Ernest Walter Weight of Bristol, England devised and fitted a four-wheel hydraulic (oil) braking system to a motor car. He patented it in Great Britain (GB190800241A) in December 1908, later in Europe and the USA and then exhibited it at the 1909 London Motor Show. His brother, William Herbert Weight improved the patent (GB190921122A) and both were assigned to the Weight Patent Autom ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Leaf Spring

A leaf spring is a simple form of spring commonly used for the suspension in wheeled vehicles. Originally called a ''laminated'' or ''carriage spring'', and sometimes referred to as a semi-elliptical spring, elliptical spring, or cart spring, it is one of the oldest forms of vehicle suspension. A leaf spring is one or more narrow, arc-shaped, thin plates which are attached to the axle and chassis in a way that allows the leaf spring to flex vertically in response to irregularities in the road surface. Lateral leaf springs are the most commonly used arrangement, running the length of the vehicle and mounted perpendicular to the wheel axle, but numerous examples of transverse leaf springs exist as well. Leaf springs can serve multiple suspension functions: location, springing, and to some extent damping as well, through interleaf friction. However, this friction is not well controlled, resulting in stiction and irregular suspension motions. For this reason, some manufacturers have ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clutch

A clutch is a mechanical device that engages and disengages power transmission, especially from a drive shaft to a driven shaft. In the simplest application, clutches connect and disconnect two rotating shafts (drive shafts or line shafts). In these devices, one shaft is typically attached to an engine or other power unit (the driving member), while the other shaft (the driven member) provides output power for work. Typically the motions involved are rotary, but linear clutches also exist. In a motor vehicle, the clutch acts as a mechanical linkage between the engine and transmission, and briefly disconnects, or separates the engine from the transmission system. This disconnects the drive wheels whenever the clutch pedal is depressed, allowing the driver to smoothly change gears. In a torque-controlled drill, for instance, one shaft is driven by a motor, and the other drives a drill chuck. The clutch connects the two shafts so they may be locked together and spin at the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rear-wheel Drive

Rear-wheel drive (RWD) is a form of engine and transmission layout used in motor vehicles, in which the engine drives the rear wheels only. Until the late 20th century, rear-wheel drive was the most common configuration for cars. Most rear-wheel drive vehicles feature a longitudinally-mounted engine at the front of the car. Layout The most common layout for a rear-wheel drive car is with the engine and transmission at the front of the car, mounted longitudinally. Other layouts of rear-wheel drive cars include front-mid engine, rear-mid engine, and rear-engine. Some manufacturers, such as Alfa Romeo, Lancia, Porsche (944, 924, 928) and Chevrolet (C5, C6, and C7 Corvettes), place the engine at the front of the car and the transmission at the rear of the car, in order to provide a more balanced weight distribution. This configuration is often referred to as a transaxle since the transmission and axle are one unit. History 1890s to 1960s Many of the cars built in the 19t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Transmission (mechanics)

Propulsion transmission is the mode of transmitting and controlling propulsion power of a machine. The term ''transmission'' properly refers to the whole drivetrain, including clutch, gearbox, prop shaft (for rear-wheel drive vehicles), differential, and final drive shafts. In the United States the term is sometimes used in casual speech to refer more specifically to the gearbox alone, and detailed usage differs. The transmission reduces the higher engine speed to the slower wheel speed, increasing torque in the process. Transmissions are also used on pedal bicycles, fixed machines, and where different rotational speeds and torques are adapted. Often, a transmission has multiple gear ratios (or simply "gears") with the ability to switch between them as the speed varies. This switching may be done manually (by the operator) or automatically (by a control unit). Directional (forward and reverse) control may also be provided. Single-ratio transmissions also exist, which simply cha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Saviem SM8

The Saviem SM8 (8-ton payload) was a range of medium-duty trucks manufactured by the French manufacturer Saviem between 1967 and 1975. The truck was part of the Saviem SM range. Characteristics Dimensions The cabin was a tip cab (Type 812). The range had a rigid form and two tractor units (SM8 T, SM8 Y). The wheelbases were between 3m and 5.3m. Engines The engine used for the SM8 (and also the SM7) was the 597/797, an atmospheric with a power output of at 2900 rpm (on its later evolutions) and a torque of at 1700 rpm. Transmission A 5-speed (4 synchronised) 301-12 manual gearbox was mounted as standard. Suspension The SM8 had a suspension of leaf springs with dampers at the front and rear. SM8 4x4 The SM8 4x4 was the four-wheel-drive version of the SM8. It was used as an off-roader and military vehicle. It was a permanent 4x4 with locking centre differential in the transfer case. The SM8 4x4 also had a differential lock A locking differential is a mechanical compo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Injection

Fuel injection is the introduction of fuel in an internal combustion engine, most commonly automotive engines, by the means of an injector. This article focuses on fuel injection in reciprocating piston and Wankel rotary engines. All compression-ignition engines (e.g. diesel engines), and many spark-ignition engines (i.e. petrol engines, such as Otto or Wankel), use fuel injection of one kind or another. Mass-produced diesel engines for passenger cars (such as the Mercedes-Benz OM 138) became available in the late 1930s and early 1940s, being the first fuel-injected engines for passenger car use. In passenger car petrol engines, fuel injection was introduced in the early 1950s and gradually gained prevalence until it had largely replaced carburettors by the early 1990s. The primary difference between carburetion and fuel injection is that fuel injection atomizes the fuel through a small nozzle under high pressure, while a carburettor relies on suction created by intake ai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Revolutions Per Minute

Revolutions per minute (abbreviated rpm, RPM, rev/min, r/min, or with the notation min−1) is a unit of rotational speed or rotational frequency for rotating machines. Standards ISO 80000-3:2019 defines a unit of rotation as the dimensionless unit equal to 1, which it refers to as a revolution, but does not define the revolution as a unit. It defines a unit of rotational frequency equal to s−1. The superseded standard ISO 80000-3:2006 did however state with reference to the unit name 'one', symbol '1', that "The special name revolution, symbol r, for this unit is widely used in specifications on rotating machines." The International System of Units (SI) does not recognize rpm as a unit, and defines the unit of frequency, Hz, as equal to s−1. :\begin 1~&\text &&=& 60~&\text \\ \frac~&\text &&=& 1~&\text \end A corresponding but distinct quantity for describing rotation is angular velocity, for which the SI unit is the ra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.jpg)