|

Saugus Iron Works National Historic Site

Saugus Iron Works National Historic Site is a National Historic Site about 10 miles (16 kilometers) northeast of Downtown Boston in Saugus, Massachusetts. It is the site of the first integrated ironworks in North America, founded by John Winthrop the Younger and in operation between 1646 and approximately 1670. It includes the reconstructed blast furnace, forge, rolling mill, shear, slitter and a quarter-ton trip hammer. The facility is powered by seven large waterwheels, some of which are rigged to work in tandem with huge wooden gears connecting them. It has a wharf to load the iron onto ocean-going vessels, as well as a large, restored 17th-century house. History During the 17th century, iron was used to manufacture a number of indispensable goods, including nails, horseshoes, cookware, tools, and weapons. The production of iron required a complex manufacturing process that could only be done by an industrial enterprise. This process was not available in North America durin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Saugus, Massachusetts

Saugus is a town in Essex County, Massachusetts, United States, in the Greater Boston area. The population was 28,619 at the 2020 census. Saugus is known as the site of the first integrated iron works in North America. History Native Americans inhabited the area around Saugus for thousands of years prior to the arrival of European settlers in the 1620s. At the time of European arrival, the Naumkeag, also known as Pawtucket, under the leadership of Montowampate were based near present day Saugus and controlled land extending from what is now Boston to the Merrimack River. English settlers took the name ''Sagus'' or ''Saugus'' from the Pawtucket word for "outlet," and used the term to refer to the Saugus River and the region that includes the present day cities and towns of Swampscott, Nahant, Lynn, Lynnfield, Reading, North Reading and Wakefield) which were later renamed Lin or Lynn in 1637, after King's Lynn in Norfolk, England. In 1646, the Saugus Iron Works, then called Ham ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Richard Leader

Richard Leader (1609–1661) was an English businessman who was the first manager of the Saugus Iron Works, the first integrated ironworks in North America. He later engaged in business in Maine and Barbados. Early life Leader was born in 1609. On October 11, 1628, he married Elizabeth Stacy of Uckfield. They had two children together. He was a merchant in Salehurst and engaged in trade between England and Ireland. Saugus Iron Works It is unknown how Leader acquired his knowledge in metallurgy, but it is likely that he had some contact with the Irish ironmaking industry. In 1645, the Company of Undertakers for the Iron Works in New England hired Leader to replace John Winthrop the Younger as manager. He was given a seven-year contract with a salary of £100 a year from the Undertakers. After arriving in Massachusetts, Leader reviewed site survey for the iron works in Braintree and looked into some other locations. He selected a location in Lynn (now part of present-day Saugus) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Battle Of Dunbar (1650)

The Battle of Dunbar was fought between the English New Model Army, under Oliver Cromwell and a Scottish army commanded by David Leslie, on 3 September 1650 near Dunbar, Scotland. The battle resulted in a decisive victory for the English. It was the first major battle of the 1650 invasion of Scotland, which was triggered by Scotland's acceptance of Charles II as king of Britain after the beheading of his father, Charles I on 30 January 1649. After Charles I's execution, the English Rump Parliament established a republican Commonwealth in England. When their erstwhile ally, Scotland, recognised Charles II as king of all of Britain on 1 May 1650 and began recruiting an army to support him, the English dispatched the New Model Army, under the command of Cromwell. The army crossed into Scotland on 22 July, with a force of over 16,000 men. The Scots withdrew to Edinburgh, stripping the land of provisions. Cromwell attempted to draw the Scots out into a set piece battle, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

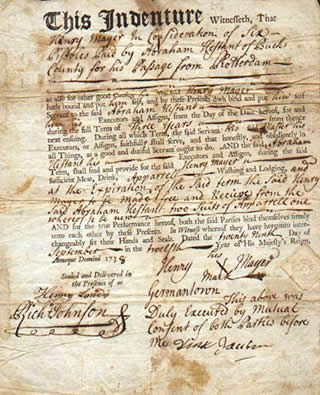

Indentured Servant

Indentured servitude is a form of labor in which a person is contracted to work without salary for a specific number of years. The contract, called an " indenture", may be entered "voluntarily" for purported eventual compensation or debt repayment, or it may be imposed as a judicial punishment. Historically, it has been used to pay for apprenticeships, typically when an apprentice agreed to work for free for a master tradesman to learn a trade (similar to a modern internship but for a fixed length of time, usually seven years or less). Later it was also used as a way for a person to pay the cost of transportation to colonies in the Americas. Like any loan, an indenture could be sold; most employers had to depend on middlemen to recruit and transport the workers so indentures (indentured workers) were commonly bought and sold when they arrived at their destinations. Like prices of slaves, their price went up or down depending on supply and demand. When the indenture (loan) was paid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cast Iron

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impurities which allow cracks to pass straight through, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1–3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable cast irons. With its relatively low melting point, good fluidity, castability, excellent machinability, resistance to deformation and wear resistance, cast irons have become an engineering material with a wide range of applications and are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wrought Iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag Inclusion (mineral), inclusions (up to 2% by weight), which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to structural failure, failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welding, forge welded, but is more difficult to welding, weld electrically. Before the development of effective methods of steelmaking and the availability of large quantities of steel, wrought iron was the most common form of malleable iron. It was given the name ''wrought'' because it was hammered, rolled, or otherwise worked while hot enough to expel molten slag. The modern functional equivalent of wrought iron is Carbon steel#Mild or low-carbon steel, mild steel, also called low-carbon steel. Neither wrought iron nor mild steel contain enough carbon to be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fireplace Fireback

A fireplace fireback is a piece of heavy cast iron, sized in proportion to the fireplace and the fire, which is placed against the back wall of the fireplace. Functions The primary functions of a fireback are to protect the wall at the back of the fireplace and radiate heat from the fire into the room. The protection was especially important where the wall was constructed of insubstantial material such as daub (a mud and straw mixture coating interwoven wooden wattles), brick or soft stone. Protective metal plates that became available when cast iron was developed enabled fires to be placed against walls without danger to the fabric of the building. The other function of the fireback is to act as a radiator of stored heat. The metal is heated by the fire, and then that heat is radiated into the room. The thick iron keeps the heat which would otherwise be lost and gives back this heat to the room. A fireback thus may increase the efficiency of the fire. Wood fires have low efficienc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gray Iron

Gray iron, or grey cast iron, is a type of cast iron that has a graphitic microstructure. It is named after the gray color of the fracture it forms, which is due to the presence of graphite.. It is the most common cast iron and the most widely used cast material based on weight.. It is used for housings where the stiffness of the component is more important than its tensile strength, such as internal combustion engine cylinder blocks, pump housings, valve bodies, electrical boxes, and decorative castings. Grey cast iron's high thermal conductivity and specific heat capacity are often exploited to make cast iron cookware and disc brake rotors. Its former widespread use on brakes in freight trains has been greatly reduced in the European Union over concerns regarding noise pollution. Deutsche Bahn for example had replaced grey iron brakes on 53,000 of its freight cars (85% of their fleet) with newer, quieter models by 2019—in part to comply with a law that came into force in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pig Iron

Pig iron, also known as crude iron, is an intermediate product of the iron industry in the production of steel which is obtained by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silica and other constituents of dross, which makes it brittle and not useful directly as a material except for limited applications. The traditional shape of the molds used for pig iron ingots is a branching structure formed in sand, with many individual ingots at right angles to a central channel or "runner", resembling a litter of piglets being nursed by a sow. When the metal had cooled and hardened, the smaller ingots (the "pigs") were simply broken from the runner (the "sow"), hence the name "pig iron". As pig iron is intended for remelting, the uneven size of the ingots and the inclusion of small amounts of sand cause only insignificant problems considering the ease of casting and handling them. History Smelting and producing wroug ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nahant, Massachusetts

Nahant is a town in Essex County, Massachusetts, United States. The population was 3,334 at the 2020 census, which makes it the smallest municipality by population in Essex County. With just of land area, it is the smallest municipality by area in the state. It is primarily a residential community. The town is situated on peninsula consisting of two near-islands (known as "Little Nahant" and "Big Nahant" respectively) connected to the mainland by a narrow sandy isthmus traversed by a single causeway known as "Nahant Road". Numerous tourist beaches line the shores, with the most popular being the so-called "Long Beach" and "Short Beach" along the eastern side of the causeway. History The area around Nahant was inhabited for thousands of years prior to European colonization of the Americas, but little is known of this period until European records began to document the area in the early 1600s. At that time, the seat of "Sagamore James" of the Naumkeag, known in his own tongue ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gabbro

Gabbro () is a phaneritic (coarse-grained), mafic intrusive igneous rock formed from the slow cooling of magnesium-rich and iron-rich magma into a holocrystalline mass deep beneath the Earth's surface. Slow-cooling, coarse-grained gabbro is chemically equivalent to rapid-cooling, fine-grained basalt. Much of the Earth's oceanic crust is made of gabbro, formed at mid-ocean ridges. Gabbro is also found as plutons associated with continental volcanism. Due to its variant nature, the term ''gabbro'' may be applied loosely to a wide range of intrusive rocks, many of which are merely "gabbroic". By rough analogy, gabbro is to basalt as granite is to rhyolite. Etymology The term "gabbro" was used in the 1760s to name a set of rock types that were found in the ophiolites of the Apennine Mountains in Italy. It was named after Gabbro, a hamlet near Rosignano Marittimo in Tuscany. Then, in 1809, the German geologist Christian Leopold von Buch used the term more restrictively in his descri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flux (metallurgy)

In metallurgy, a flux () is a chemical cleaning agent, flowing agent, or purifying agent. Fluxes may have more than one function at a time. They are used in both extractive metallurgy and metal joining. Some of the earliest known fluxes were sodium carbonate, potash, charcoal, coke, borax, lime, lead sulfide and certain minerals containing phosphorus. Iron ore was also used as a flux in the smelting of copper. These agents served various functions, the simplest being a reducing agent, which prevented oxides from forming on the surface of the molten metal, while others absorbed impurities into the slag, which could be scraped off the molten metal. Fluxes are also used in foundries for removing impurities from molten nonferrous metals such as aluminium, or for adding desirable trace elements such as titanium. As cleaning agents, fluxes facilitate soldering, brazing, and welding by removing oxidation from the metals to be joined. In some applications molten flux also serve ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |