|

Stack Light

Stack lights (also known as signal tower lights, indicator lights, andon lights, warning lights, industrial signal lights, or tower lights) are commonly used on equipment in industrial manufacturing and process control environments to provide visual and audible indicators of a machine's status to machine operators, technicians, production managers and factory personnel. They are a form of andon: a manufacturing system that identifies errors as they happen. General Stack lights are used in similar applications to beacon lights/strobes, however the information they typically display encompasses more machine/process conditions. Stack lights typically use incandescent, LED or xenon-type strobes as their illumination source. Stack lights are generally columnar structures in a variety of shapes, placing colour-coded indicator segments on top of one another in a "stacked" orientation. A stack light will typically have up to five differently coloured segments to indicate various condit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SCADA

Supervisory control and data acquisition (SCADA) is a control system architecture comprising computers, networked data communications and graphical user interfaces for high-level supervision of machines and processes. It also covers sensors and other devices, such as programmable logic controllers, which interface with process plant or machinery. Explanation The operator interfaces which enable monitoring and the issuing of process commands, like controller set point changes, are handled through the SCADA computer system. The subordinated operations, e.g. the real-time control logic or controller calculations, are performed by networked modules connected to the field sensors and actuators. The SCADA concept was developed to be a universal means of remote-access to a variety of local control modules, which could be from different manufacturers and allowing access through standard automation protocols. In practice, large SCADA systems have grown to become very similar to distr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

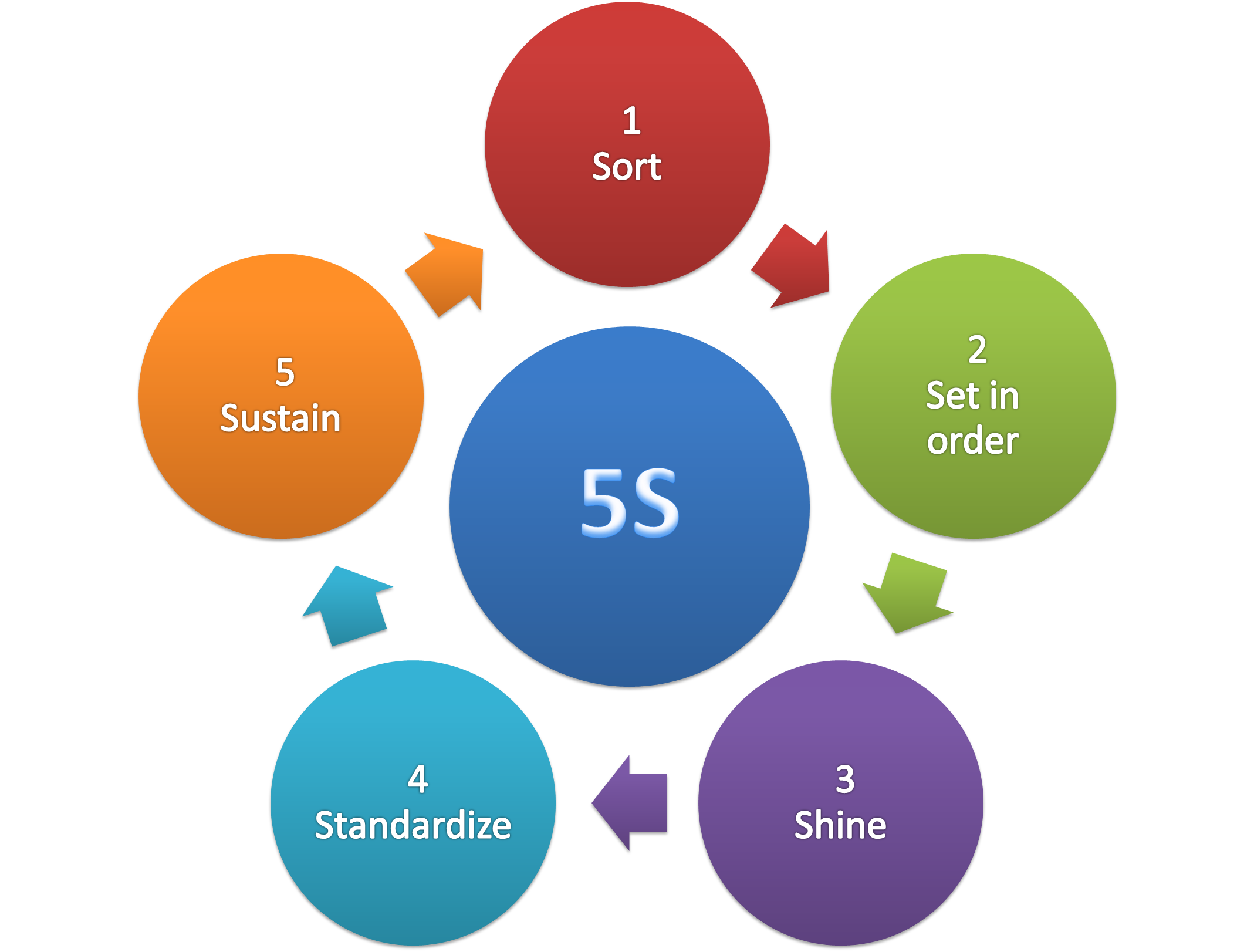

5S (methodology)

5S is a workplace organization method that uses a list of five Japanese language, Japanese words: , , , , and . These have been translated as "sort", "set in order", "shine", "standardize", and "sustain". The list describes how to organize a work space for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new organizational system. The decision-making process usually comes from a dialogue about standardization, which builds understanding among employees of how they should do the work. In some quarters, 5S has become 6S, the sixth element being safety (safe). Other than a specific stand-alone methodology, 5S is frequently viewed as an element of a broader construct known as ''visual control'', ''visual workplace'', or ''visual factory''. Under those (and similar) terminologies, Western companies were applying underlying concepts of 5S before publication, in English, of the formal 5S methodology. For example, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing is particularly related to the operational model implemented in the post-war 1950s and 1960s by the Japa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Productivity Improving Technologies (historical)

The productivity-improving technologies are the technological innovations that have historically increased productivity. Productivity is often measured as the ratio of (aggregate) output to (aggregate) input in the production of goods and services. Productivity is increased by lowering the amount of labor, capital, energy or materials that go into producing any given amount of economic goods and services. Increases in productivity are largely responsible for the increase in per capita living standards. History Productivity-improving technologies date back to antiquity, with rather slow progress until the late Middle Ages. Important examples of early to medieval European technology include the water wheel, the horse collar, the spinning wheel, the three-field system (after 1500 the four-field system—see crop rotation) and the blast furnace. All of these technologies had been in use in China, some for centuries, before being introduced to Europe. Technological progress was ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sound Pressure Level

Sound pressure or acoustic pressure is the local pressure deviation from the ambient (average or equilibrium) atmospheric pressure, caused by a sound wave. In air, sound pressure can be measured using a microphone, and in water with a hydrophone. The SI unit of sound pressure is the pascal (Pa). Mathematical definition A sound wave in a transmission medium causes a deviation (sound pressure, a ''dynamic'' pressure) in the local ambient pressure, a ''static'' pressure. Sound pressure, denoted ''p'', is defined by p_\text = p_\text + p, where * ''p''total is the total pressure, * ''p''stat is the static pressure. Sound measurements Sound intensity In a sound wave, the complementary variable to sound pressure is the particle velocity. Together, they determine the sound intensity of the wave. ''Sound intensity'', denoted I and measured in W· m−2 in SI units, is defined by \mathbf I = p \mathbf v, where * ''p'' is the sound pressure, * v is the particle velocity. Acoustic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Buzzer

A buzzer or beeper is an audio signaling device, which may be mechanical, electromechanical, or piezoelectric (''piezo'' for short). Typical uses of buzzers and beepers include alarm devices, timers, train and confirmation of user input such as a mouse click or keystroke. History Electromechanical The electric buzzer was invented in 1831 by Joseph Henry. They were mainly used in early doorbells until they were phased out in the early 1930s in favor of musical chimes, which had a softer tone. Piezoelectric Piezoelectric buzzers, or piezo buzzers, as they are sometimes called, were invented by Japanese manufacturers and fitted into a wide array of products during the 1970s to 1980s. This advancement mainly came about because of cooperative efforts by Japanese manufacturing companies. In 1951, they established the Barium Titanate Application Research Committee, which allowed the companies to be "competitively cooperative" and bring about several piezoelectric innovations and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Emergency Stop

A kill switch, also known as an emergency stop (E-stop), emergency off (EMO) and as an emergency power off (EPO), is a safety mechanism used to shut off machinery in an emergency, when it cannot be shut down in the usual manner. Unlike a normal shut-down switch or shut-down procedure, which shuts down all systems in order and turns off the machine without damage, a kill switch is designed and configured to abort the operation as quickly as possible (even if it damages the equipment) and to be operated simply and quickly (so that even a panicked operator with impaired executive functions or a bystander can activate it). Kill switches are usually designed to be noticeable, even to an untrained operator or a bystander. Some kill switches feature a removable, protective barrier against accidental activation (e.g. a plastic cover that must be lifted or glass that must be broken), known as a mollyguard. Kill switches are features of mechanisms whose normal operation or foreseeable mi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stack Light Reference Image

Stack may refer to: Places * Stack Island, an island game reserve in Bass Strait, south-eastern Australia, in Tasmania’s Hunter Island Group * Blue Stack Mountains, in Co. Donegal, Ireland People * Stack (surname) (including a list of people with the name) * Parnell "Stacks" Edwards, a key associate in the Lufthansa heist * Robert Stack Pierce (1933–2016), an American actor and baseball player * Brian "Stack" Stevens (1941–2017), a Cornish rugby player * Stacks (rapper) (born 1985), the stage name of the rapper Yannique Barker Arts, entertainment, and media * ''Stack magazine'', a bimonthly publication about high school sports * ''Stacks'' (album), a 2005 album by Bernie Marsden * Stacks, trailer parks that were made vertical, in the film ''Ready Player One'' Computing * Stack (abstract data type), abstract data type and data structure based on the principle of last in first out ** Stack (C++), a C++ standard container, simulating a stack * Stack (Haskell), a tool to b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |