|

Shock Hardening

Shock hardening is a process used to strengthen metals and alloys, wherein a shock wave produces atomic-scale defects in the material's crystalline structure. As in cold work, these defects interfere with the normal processes by which metallic materials yield (plasticity), making materials stiffer, but more brittle. When compared to traditional cold work, such an extremely rapid process results in a different class of defect, producing a much harder material for a given change in shape. If the shock wave applies too great a force for too long, however, the rarefaction front that follows it can form voids in the material due to hydrostatic tension, weakening the material and often causing it to spall. Since voids nucleate at large defects, such as oxide inclusions and grain boundaries, high-purity samples with a large grain size (especially single crystals) are able to withstand greater shock without spalling, and can therefore be made much harder. Shock hardening has b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strength Of Materials

The field of strength of materials, also called mechanics of materials, typically refers to various methods of calculating the stresses and strains in structural members, such as beams, columns, and shafts. The methods employed to predict the response of a structure under loading and its susceptibility to various failure modes takes into account the properties of the materials such as its yield strength, ultimate strength, Young's modulus, and Poisson's ratio. In addition, the mechanical element's macroscopic properties (geometric properties) such as its length, width, thickness, boundary constraints and abrupt changes in geometry such as holes are considered. The theory began with the consideration of the behavior of one and two dimensional members of structures, whose states of stress can be approximated as two dimensional, and was then generalized to three dimensions to develop a more complete theory of the elastic and plastic behavior of materials. An important founding p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various ''time setting'' materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC. History Throughout history, metal casting has been used to make tools, weapons, and religious objects. Metal casting history and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Laser Articles

This is a list of laser topics. A * 3D printing, additive manufacturing * Abnormal reflection * Above-threshold ionization * Absorption spectroscopy * Accelerator physics * Acoustic microscopy * Acousto-optic deflector * Acousto-optic modulator * Acousto-optical spectrometer * Acousto-optics * Active laser medium * Active optics * Advanced Precision Kill Weapon System * Advanced Tactical Laser * Afocal system * Airborne laser * Airborne wind turbine * Airy beam * ALKA * All gas-phase iodine laser * Ambient ionization * Amplified spontaneous emission * Analytical chemistry * Aneutronic fusion * Antiproton Decelerator * Apache Arrowhead * Apache Point Observatory Lunar Laser-ranging Operation * Arago spot * Argon fluoride laser * Argus laser * Asterix IV laser * Astrophysical maser * Atmospheric-pressure laser ionization * Atom interferometer * Atom laser * Atom probe * Atomic clock * Atomic coherence * Atomic fountain * Atomic line filter * Atomic ratio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

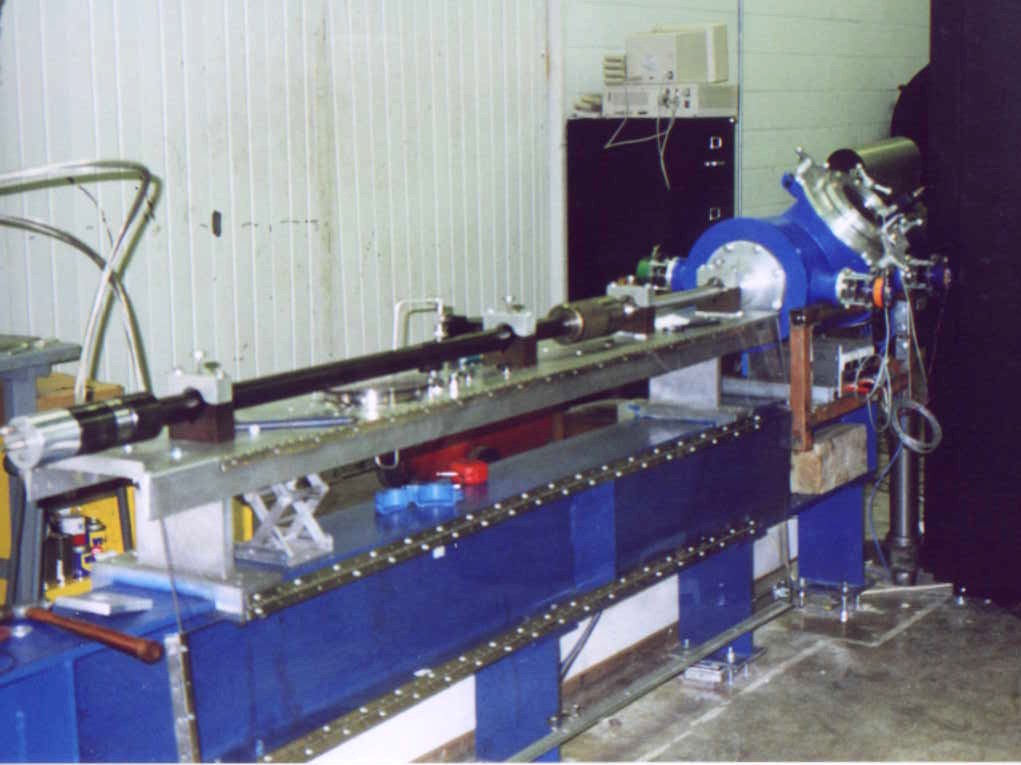

Light-gas Gun

The light-gas gun is an apparatus for physics experiments. It is a highly specialized gun designed to generate extremely high velocities. It is usually used to study high-speed impact phenomena (hypervelocity research), such as the formation of impact craters by meteorites or the erosion of materials by micrometeoroids. Some basic material research relies on projectile impact to create high pressure; such systems are capable of forcing liquid hydrogen into a metallic state. Operation A light-gas gun works on the same principle as a spring piston airgun. A large-diameter piston is used to force a gaseous working fluid through a smaller-diameter barrel containing the projectile to be accelerated. This reduction in diameter acts as a lever, increasing the speed while decreasing the pressure. In an airgun, the large piston is powered by a spring or compressed air, and the working fluid is atmospheric air. In a light-gas gun, the piston is powered by a chemical reaction (usually g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Amorphous Solid

In condensed matter physics and materials science, an amorphous solid (or non-crystalline solid, glassy solid) is a solid that lacks the long-range order that is characteristic of a crystal. Etymology The term comes from the Greek ''a'' ("without"), and ''morphé'' ("shape, form"). In some older articles and books, the term was used synonymously with glass. Today, "glassy solid" or "amorphous solid" is considered the overarching concept. Polymers are often amorphous. Structure Amorphous materials have an internal structure comprising interconnected structural blocks that can be similar to the basic structural units found in the corresponding crystalline phase of the same compound. Unlike crystalline materials, however, no long-range order exists. Localized order in amorphous materials can be categorized as short or medium range order. By convention, short range order extends only to the nearest neighbor shell, typically only 1-2 atomic spacings. Medium range order is the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spallation Spallation is a process in which fragments of material ( spall) are ejected from a body due to impact or stress. In the context of impact mechanics it describes ejection of material from a target during impact by a projectile. In planetary physics, spallation describes meteoritic impacts on a planetary surface and the effects of stellar winds and cosmic rays on planetary atmospheres and surfaces. In the context of mining or geology, |