|

Sheet Metal Forming Simulation

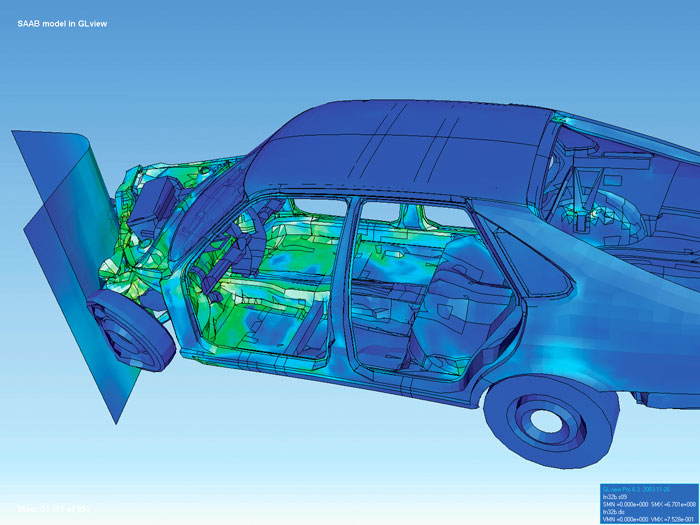

Today the metal forming industry is making increasing use of simulation to evaluate the performing of dies, processes and blanks prior to building try-out tooling. Finite element analysis (FEA) is the most common method of simulating sheet metal forming operations to determine whether a proposed design will produce parts free of defects such as fracture or wrinkling. Sheet metal forming challenges Sheet metal forming, which is often referred to as stamping, is a process in which a piece of sheet metal, referred to as the blank, is formed by stretching between a punch and a die. The most painful and most frequent defects are wrinkles, thinning, springback and splits or cracks. Few methods are being used around the industry to cope with the main defects, based on the experience of the technicians. However, the correct process is the most vital, since it involves the correct geometry followed by number of steps to reach at final geometry. Which demands for specific experience or highe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal Forming

Forming, metal forming, is the metalworking process of fashioning metal parts and objects through mechanical deformation; the workpiece is reshaped without adding or removing material, and its mass remains unchanged. Forming operates on the materials science principle of plastic deformation, where the physical shape of a material is permanently deformed. Characteristics Metal forming tends to have more uniform characteristics across its subprocesses than its contemporary processes, cutting and joining. On the industrial scale, forming is characterized by: * Very high loads and stresses required, between 50 and () * Large, heavy, and expensive machinery in order to accommodate such high stresses and loads * Production runs with many parts, to maximize the economy of production and compensate for the expense of the machine tools Forming processes Forming processes tend to be categorised by differences in effective stresses. These categories and descriptions are highly simplifie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Simulation

A simulation is the imitation of the operation of a real-world process or system over time. Simulations require the use of Conceptual model, models; the model represents the key characteristics or behaviors of the selected system or process, whereas the simulation represents the evolution of the model over time. Often, computers are used to execute the computer simulation, simulation. Simulation is used in many contexts, such as simulation of technology for performance tuning or optimizing, safety engineering, testing, training, education, and video games. Simulation is also used with scientific modelling of natural systems or human systems to gain insight into their functioning, as in economics. Simulation can be used to show the eventual real effects of alternative conditions and courses of action. Simulation is also used when the real system cannot be engaged, because it may not be accessible, or it may be dangerous or unacceptable to engage, or it is being designed bu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finite Element Analysis

The finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. The FEM is a general numerical method for solving partial differential equations in two or three space variables (i.e., some boundary value problems). To solve a problem, the FEM subdivides a large system into smaller, simpler parts that are called finite elements. This is achieved by a particular space discretization in the space dimensions, which is implemented by the construction of a mesh of the object: the numerical domain for the solution, which has a finite number of points. The finite element method formulation of a boundary value problem finally results in a system of algebraic equations. The method approximates the unknown function over the domain. The sim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stamping (metalworking)

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined. Stamping is usually ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bending (metalworking)

Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal.Manufacturing Processes Reference Guide, Industrial Press Inc., 1994. Commonly used equipment include box and pan brakes, brake presses, and other specialized machine presses. Typical products that are made like this are boxes such as electrical enclosures and rectangular ductwork. Process In press brake forming, a work piece is positioned over the die block and the die block presses the sheet to form a shape. Usually bending has to overcome both tensile stresses and compressive stresses. When bending is done, the residual stresses cause the material to ' towards its original position, so the sheet must be over-bent to achieve the proper bend angle. The amount of spring back is dependent on the material, and the type of forming. When sheet metal is bent, it stretches in length. The ''bend deduction'' is the amount t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finite Difference Method

In numerical analysis, finite-difference methods (FDM) are a class of numerical techniques for solving differential equations by approximating derivatives with finite differences. Both the spatial domain and time interval (if applicable) are discretized, or broken into a finite number of steps, and the value of the solution at these discrete points is approximated by solving algebraic equations containing finite differences and values from nearby points. Finite difference methods convert ordinary differential equations (ODE) or partial differential equations (PDE), which may be nonlinear, into a system of linear equations that can be solved by matrix algebra techniques. Modern computers can perform these linear algebra computations efficiently which, along with their relative ease of implementation, has led to the widespread use of FDM in modern numerical analysis. Today, FDM are one of the most common approaches to the numerical solution of PDE, along with finite element metho ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Progressive Strip Simulated Thinning, AutoForm

Progressive may refer to: Politics * Progressivism, a political philosophy in support of social reform ** Progressivism in the United States, the political philosophy in the American context * Progressive realism, an American foreign policy paradigm focused on producing measurable results in pursuit of widely supported goals Political organizations * Congressional Progressive Caucus, members within the Democratic Party in the United States Congress dedicated to the advancement of progressive issues and positions * Progressive Alliance (other) * Progressive Conservative (other) * Progressive Party (other) * Progressive Unionist (other) Other uses in politics * Progressive Era, a period of reform in the United States (c. 1890–1930) * Progressive tax, a type of tax rate structure Arts, entertainment, and media Music * Progressive music, a type of music that expands stylistic boundaries outwards * "Progressive" (song), a 2009 single b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tata Motors

Tata Motors Limited is an Indian multinational automotive manufacturing company, headquartered in Mumbai, India, which is part of the Tata Group. The company produces passenger cars, trucks, vans, coaches, buses. Formerly known as Tata Engineering and Locomotive Company (TELCO), the company was founded in 1945 as a manufacturer of locomotives. The company manufactured its first commercial vehicle in 1954 in a collaboration with Daimler-Benz AG, which ended in 1969. Tata Motors entered the passenger vehicle market in 1988 with the launch of the TataMobile followed by the Tata Sierra in 1991, becoming the first Indian manufacturer to achieve the capability of developing a competitive indigenous automobile. In 1998, Tata launched the first fully indigenous Indian passenger car, the Indica, and in 2008 launched the Tata Nano, the world's most affordable car. Tata Motors acquired the South Korean truck manufacturer Daewoo Commercial Vehicles Company in 2004. Tata Motors has b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nissan Motor Company

, trading as Nissan Motor Corporation and often shortened to Nissan, is a Japanese multinational automobile manufacturer headquartered in Nishi-ku, Yokohama, Japan. The company sells its vehicles under the Nissan, Infiniti, and Datsun brands, with in-house performance tuning products (including cars) labelled Nismo. The company traces back to the beginnings of the 20th century, with the Nissan ''zaibatsu'', now called Nissan Group. Since 1999, Nissan has been part of the Renault–Nissan–Mitsubishi Alliance (Mitsubishi joining in 2016), a partnership between Nissan and Mitsubishi Motors of Japan, with Renault of France. , Renault holds a 43.4% voting stake in Nissan, while Nissan holds a 15% non-voting stake in Renault. Since October 2016 Nissan has held a 34% controlling stake in Mitsubishi Motors. In 2013, Nissan was the sixth largest automaker in the world, after Toyota, General Motors, Volkswagen Group, Hyundai Motor Group, and Ford. In 2014, Nissan was the largest car ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal Forming

Forming, metal forming, is the metalworking process of fashioning metal parts and objects through mechanical deformation; the workpiece is reshaped without adding or removing material, and its mass remains unchanged. Forming operates on the materials science principle of plastic deformation, where the physical shape of a material is permanently deformed. Characteristics Metal forming tends to have more uniform characteristics across its subprocesses than its contemporary processes, cutting and joining. On the industrial scale, forming is characterized by: * Very high loads and stresses required, between 50 and () * Large, heavy, and expensive machinery in order to accommodate such high stresses and loads * Production runs with many parts, to maximize the economy of production and compensate for the expense of the machine tools Forming processes Forming processes tend to be categorised by differences in effective stresses. These categories and descriptions are highly simplifie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |