|

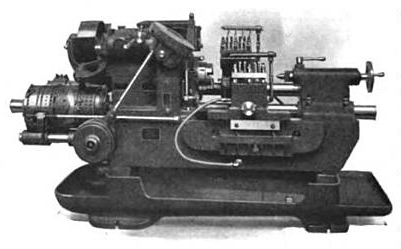

Screw Machine (automatic Lathe)

In metalworking and woodworking, an automatic lathe is a lathe with an automatically controlled cutting process. Automatic lathes were first developed in the 1870s and were mechanically controlled. From the advent of NC and CNC in the 1950s, the term automatic lathe has generally been used for only mechanically controlled lathes, although some manufacturers (e.g., DMG Mori and Tsugami) market Swiss-type CNC lathes as 'automatic'. CNC has not yet entirely displaced mechanically automated lathes, as although no longer in production, many mechanically automated lathes remain in service. General nomenclature The term "automatic lathe" is still often used in manufacturing in its earlier sense, referring to automated lathes of non- CNC types. The first automatic lathes were mechanically automated and controlled by cams or tracers and pantographs. Thus, before electronic automation via numerical control, the "automatic" in the term "automatic machine tool" always referred implic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fay Automatic Lathe

The Fay automatic lathe was an automatic lathe tailored to cutting workpieces that were mounted on Lathe center, centers (tools with pointed ends to accurately position a Drill bit#Center and spotting drill bit, center-drilled workpiece about an axis, either directly or by using a mandrel). It could also do chucking work. (feeding of unformed blanks or pieces of stock from a magazine to be automatically gripped by the machine for turning). Examples of workpieces included automotive steering knuckles and transmission gears, and such work done on mandrels as flanges, disks, and hubs. The machine tool was developed by F.C. Fay of Philadelphia and improved by Otto A. Schaum. It was originally manufactured by the Fay & Scott Machine Shop. James Hartness acquired manufacturing rights on behalf of the Jones & Lamson Machine Company. and manufactured an improved version, developed under the management of Ralph Flanders.. In 1937 Roe, writing for the American Society of Mechanical Engineer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

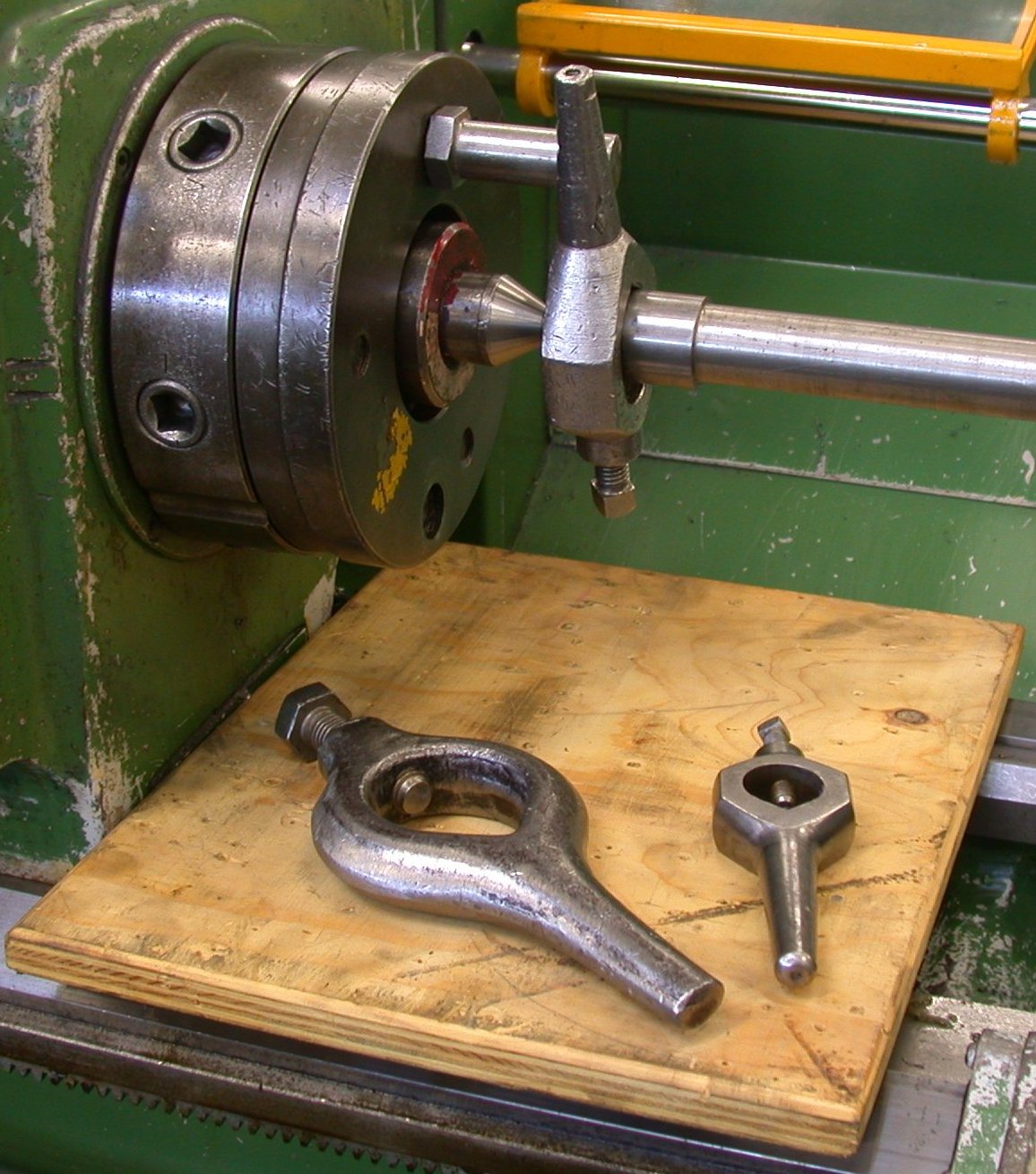

Lathe Center

A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis. They usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used. The primary use of a center is to ensure concentric work is produced; this allows the workpiece to be transferred between machining (or inspection) operations without any loss of accuracy. A part may be ''turned'' in a lathe, sent off for hardening and tempering and then ground ''between centers'' in a cylindrical grinder. The preservation of concentricity between the turning and grinding operations is crucial for quality work. When turning between centers, a steady rest can be used to support longer workpieces where the cutting forces would deflect the work excessively, reducing the finish and accuracy of the workpiece, or creating a hazardous situation. A lathe center has applications anywhere that a ''centered'' workpiece may be used; this i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pneumatic Tool

A pneumatic tool, air tool, air-powered tool or pneumatic-powered tool is a type of power tool, driven by compressed air supplied by an air compressor. Pneumatic tools can also be driven by compressed carbon dioxide () stored in small cylinders allowing for portability. Most pneumatic tools convert the compressed air to work using a pneumatic motor. Compared to electric power tool equivalents, pneumatic tools are safer to run and maintain, without risk of sparks, short-circuiting or electrocution, and have a higher power to weight ratio, allowing a smaller, lighter tool to accomplish the same task. Furthermore, they are less likely to self-destruct in case the tool is jammed or overloaded. General grade pneumatic tools with a short life span are commonly less expensive and considered “disposable tools” in tooling industries, while industrial grade pneumatic tools with long life span are more expensive. In general, pneumatic tools are cheaper than the equivalent electric-power ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lathe (metal)

In machining, a metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials. In machining jargon, where the larger context is already understood, they are usually simply called ''lathes'', or else referred to by more-specific subtype names ('' toolroom lathe'', '' turret lathe'', etc.). These rigid machine tools remove material from a rotating workpiece via the (typically linear) movements of various cutting tools, such as tool bits and drill bits. Metal lathes can vary greatly, but the most common design is known as the universal lathe or parallel lathe. Construction The design of lathes can vary greatly depending on the intended application; however, basic features are common to most types. These ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spindle (tool)

In machine tools, a spindle is a rotating axis of the machine, which often has a shaft at its heart. The shaft itself is called a spindle, but also, in shop-floor practice, the word often is used metonymically to refer to the entire rotary unit, including not only the shaft itself, but its bearings and anything attached to it ( chuck, etc.). Spindles are electrically or pneumatically powered and come in various sizes. They are versatile in terms of material it can work with. Materials that spindles work with include embroidery, foam, glass, wood, etc. A machine tool may have several spindles, such as the headstock and tailstock spindles on a bench lathe. The main spindle is usually the biggest one. References to "the spindle" without further qualification imply the main spindle. Some machine tools that specialize in high-volume mass production have a group of 4, 6, or even more main spindles. These are called multispindle machines. For example, gang drills and many screw m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brown & Sharpe

Brown & Sharpe is a division of Hexagon AB, a Sweden, Swedish multinational corporation focused mainly on metrology, metrological tools and technology. During the 19th and 20th centuries, Brown & Sharpe was one of the best-known and most influential machine tool builders and was a leading manufacturer of instruments for machinists (such as Micrometer (device), micrometers and indicator (distance amplifying instrument), indicators). Its reputation and influence were such that its name is often considered to be inseparably paired with certain industrial standards that it helped establish, including: * The American wire gauge (AWG) standards for wire; * The Machine taper#Brown & Sharpe, Brown & Sharpe taper in machine tool spindle tapers; and * The Brown & Sharpe worm threadform for worm gears. Since being acquired by Hexagon Metrology in 2001, Brown and Sharpe has concentrated exclusively on metrology equipment. History Founding (1833) and early years Brown & Sharpe was found ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Retronym

A retronym is a newer name for something that differentiates it from something else that is newer, similar, or seen in everyday life; thus, avoiding confusion between the two. Etymology The term ''retronym'', a neologism composed of the combining forms '' retro-'' (from Latin , "before") + '' -nym'' (from Greek , "name"), was coined by Frank Mankiewicz in 1980 and popularized by William Safire in '' The New York Times Magazine''. In 2000, '' The American Heritage Dictionary'' (4th edition) became the first major dictionary to include the word ''retronym''. Examples The global war from 1914 to 1918 was referred to at the time as the ''Great War''. However, after the subsequent global war erupted in 1939, the phrase ''Great War'' was gradually deprecated. The first came to be known as ''World War I'' and the second as ''World War II''. The first bicycles with two wheels of equal size were called " safety bicycles" because they were easier to handle than the then-dominant ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turret Lathe

A turret lathe is a form of lathe (metal), metalworking lathe that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually interchangeable parts, interchangeable. It evolved from earlier lathes with the addition of the ''turret'', which is an indexing (motion), indexable toolholder that allows multiple cutting operations to be performed, each with a different Cutting tool (machining), cutting tool, in easy, rapid succession, with no need for the operator to perform set-up tasks in between (such as installing or uninstalling tools) or to control the toolpath. The latter is due to the toolpath's being controlled by the machine, either in jig (tool), jig-like fashion, via the mechanical limits placed on it by the turret's slide and stops, or via Digital electronics, digitally-directed servomechanisms for computer numerical control lathes. The name derives from the way early turrets took the general form of a flattened cylindrical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw-cutting Lathe

A screw-cutting lathe is a machine (specifically, a lathe) capable of cutting very accurate screw threads via single-point screw-cutting, which is the process of guiding the linear motion of the tool bit in a precisely known ratio to the rotating motion of the workpiece. This is accomplished by gearing the leadscrew (which drives the tool bit's movement) to the spindle with a certain gear ratio for each thread pitch. Every degree of spindle rotation is matched by a certain distance of linear tool travel, depending on the desired thread pitch (English or metric, fine or coarse, etc.). The name "screw-cutting lathe" carries a taxonomic qualification on its use—it is a term of historical classification rather than one of current commercial machine tool terminology. Early lathes, many centuries ago, were not adapted to screw-cutting. Later, from the Late Middle Ages until the early nineteenth century, some lathes were distinguishable as "screw-cutting lathes" because of the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw Thread

A screw thread is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a ''straight'' thread and the latter called a ''tapered'' thread. A screw thread is the essential feature of the screw as a simple machine and also as a threaded fastener. The mechanical advantage of a screw thread depends on its ''lead'', which is the linear distance the screw travels in one revolution. In most applications, the lead of a screw thread is chosen so that friction is sufficient to prevent linear motion being converted to rotary, that is so the screw does not slip even when linear force is applied, as long as no external rotational force is present. This characteristic is essential to the vast majority of its uses. The tightening of a fastener's screw thread is comparable to driving a wedge into a gap until it sticks fast through friction and slight ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw

A screw is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to the screw head, head. The most common uses of screws are to hold objects together and there are many forms for a variety of materials. Screws might be inserted into holes in assembled parts or a screw may form its own thread. The #Differentiation between bolt and screw, difference between a screw and a bolt is that the latter is designed to be tightened or released by torquing a Nut (hardware), nut. The screw head on one end has a slot or other feature that commonly requires a tool to transfer the twisting force. Common tools for driving screws include screwdrivers, wrenches, coins and hex keys. The head is usually larger than the body, which provides a ''bearing surface'' and keeps the screw from being driven deeper than its length; an exception being the ''set screw'' (aka grub screw). The cylindrical portion of the screw from the underside of the head t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metonymy

Metonymy () is a figure of speech in which a concept is referred to by the name of something associated with that thing or concept. For example, the word " suit" may refer to a person from groups commonly wearing business attire, such as salespeople or attorneys. Etymology The words ''metonymy'' and ''metonym'' come ; , a suffix that names figures of speech, . Background Metonymy and related figures of speech are common in everyday speech and writing. Synecdoche and metalepsis are considered specific types of metonymy. Polysemy, the capacity for a word or phrase to have multiple meanings, sometimes results from relations of metonymy. Both metonymy and metaphor involve the substitution of one term for another. In metaphor, this substitution is based on some specific analogy between two things, whereas in metonymy the substitution is based on some understood association or contiguity. American literary theorist Kenneth Burke considers metonymy as one of four "master tro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |