|

Rotary Stage

A rotary stage is a component of a motion system used to restrict an object to a single axis of rotation. The terms rotary table or rotation stage are often used interchangeably with rotary stage. All rotary stages consist of a platform and a base, joined by some form of guide in such a way that the platform is restricted to rotation about a single axis with respect to the base. In common usage, the term rotary stage may or may not also include the mechanism by which the angular position of the platform is controlled relative to the base. Principle of operation In three-dimensional space, an object may either rotate about, or translate along, any of three axes. Thus, the object is said to have six degrees of freedom (3 rotational and 3 translational). A rotary stage exhibits only one degree of freedom (rotation about one axis). In other words, rotary stages operate by physically restricting 3 axes of translation and 2 axes of rotation. Bearing types Rotary stages consist of a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Motion System

{{refimprove, date=September 2007 Motion system in engineering and systems, is a component of a test and measurement system that provides motion to a load or loads in a one or many directions. Generally a motion system is made up of a set (or stack) of linear and rotational stages. A linear stage moves in a straight line, while a rotation stage moves in a partial or full circle. A stage can either be manually controlled with a knob control, or automated with a motion controller. A motion system generally is computer controlled and can perform fast, reliable, repeatable, and accurate positioning of loads. Most systems will support motion in X and Y directions, which is referred to as an XY stack. Often either a Z axis (up/down motion) or R axis (rotational motion) is placed on top of the XY stack. For automated stages, a scale can be attached to the internals of the stage and an encoder used to measure the position on the scale and report this to the controller, thereby determin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bearing (mechanical)

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may ''prevent'' a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts. Rotary bearings hold rotating components such as shafts or axles within mechanical systems, and transfer axial and radial loads from the source of the load to the structure supporting it. The simplest form of bearing, the ''plain bearing'', consists of a shaft rotating in a hole. Lubrication is used to reduce friction. In the ''ball bearing'' and ''roller bearing'', to reduce sliding ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plain Bearing

A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading sometimes called a solid bearing, journal bearing, or friction bearing), is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore, the journal (i.e., the part of the shaft in contact with the bearing) slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe. Plain bearings, in general, are the least expensive type of bearing. They are also compact and lightweight, and they have a high load-carrying capacity. Design The design of a plain bearing depends on the type of motion the bearing must provide. The three types of motions possible are: * ''Journal'' (''friction'', ''radial'' or ''rotary'') ''bearing'': This is the most common type of p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolling-element Bearing

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding. One of the earliest and best-known rolling-element bearings are sets of logs laid on the ground with a large stone block on top. As the stone is pulled, the logs roll along the ground with little sliding friction. As each log comes out the back, it is moved to the front where the block then rolls on to it. It is possible to imitate such a bearing by placing several pens or pencils on a table and placing an item on top of them. See " bearings" for more on the historical development of bearings. A rolling element rotary bearing uses a shaft in a much larger hole, and cylinders called "rollers" tightly fill the space between t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Worm Drive

A worm drive is a gear arrangement in which a worm (which is a gear in the form of a screw) meshes with a worm wheel (which is similar in appearance to a spur gear). The two elements are also called the worm screw and worm gear. The terminology is often confused by imprecise use of the term ''worm gear'' to refer to the worm, the worm wheel, or the worm drive as a unit. The worm drive or "endless screw" was invented by either Archytas of Terentum, Apollonius of Perga, or Archimedes, the last one being the most probable author.Witold Rybczynski, '' One good turn : a natural history of the screwdriver and the screw''. London, 2000. Page 139. The worm drive later appeared in the Indian subcontinent, for use in roller cotton gins, during the Delhi Sultanate in the thirteenth or fourteenth centuries.Irfan Habib''Economic History of Medieval India, 1200–1500'', page 53 Pearson Education Explanation A gearbox designed using a worm and worm wheel is considerably smaller than on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stepper Motor

A stepper motor, also known as step motor or stepping motor, is a brushless DC electric motor that divides a full rotation into a number of equal steps. The motor's position can be commanded to move and hold at one of these steps without any position sensor for feedback (an open-loop controller), as long as the motor is correctly sized to the application in respect to torque and speed. Switched reluctance motors are very large stepping motors with a reduced pole count, and generally are closed-loop commutated. Mechanism Brushed DC motors rotate continuously when DC voltage is applied to their terminals. The stepper motor is known for its property of converting a train of input pulses (typically square waves) into a precisely defined increment in the shaft’s rotational position. Each pulse rotates the shaft through a fixed angle. Stepper motors effectively have multiple "toothed" electromagnets arranged as a stator around a central rotor, a gear-shaped piece of iron. Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Linear Actuator

A linear actuator is an actuator that creates motion in a straight line, in contrast to the circular motion of a conventional electric motor. Linear actuators are used in machine tools and industrial machinery, in computer Peripheral, peripherals such as disk drives and printers, in Valve, valves and Damper (flow), dampers, and in many other places where linear motion is required. Hydraulics, Hydraulic or Pneumatics, pneumatic cylinders inherently produce linear motion. Many other mechanisms are used to generate linear motion from a rotating motor. Types Mechanical actuators Machine, Mechanical linear actuators typically operate by conversion of rotary motion into linear motion. Conversion is commonly made via a few simple types of mechanism: * Screw (simple machine), Screw: leadscrew, screw jack, ball screw and roller screw actuators all operate on the principle of the simple machine known as the screw. By rotating the actuator's nut, the screw shaft moves in a line. * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

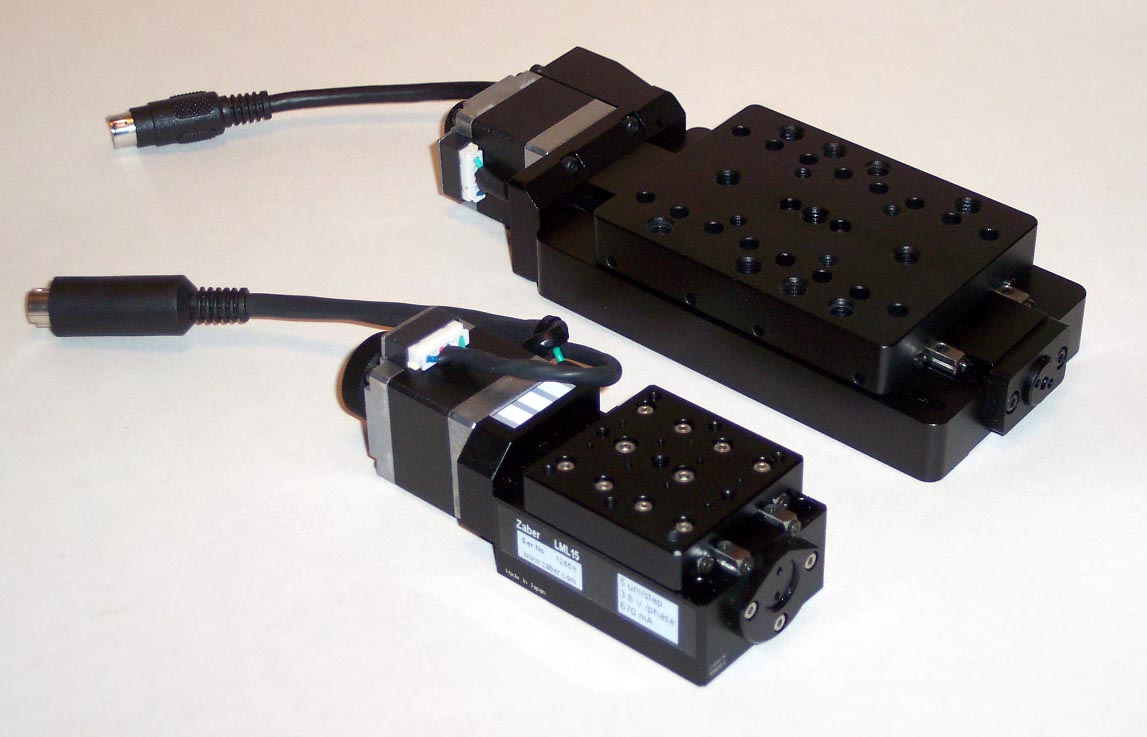

Linear Stage

A linear stage or translation stage is a component of a precise motion system used to restrict an object to a single axis of motion. The term linear slide is often used interchangeably with "linear stage", though technically "linear slide" refers to a linear motion bearing, which is only a component of a linear stage. All linear stages consist of a platform and a base, joined by some form of guide or linear bearing in such a way that the platform is restricted to linear motion with respect to the base. In common usage, the term linear stage may or may not also include the mechanism by which the position of the platform is controlled relative to the base. Principle of operation In three-dimensional space, an object may either rotate about, or translate along any of three axes. Thus the object is said to have six degrees of freedom (3 rotational and 3 translational). A linear stage exhibits only one degree of freedom (translation along one axis). In other words, linear stages opera ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plain Bearing

A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading sometimes called a solid bearing, journal bearing, or friction bearing), is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore, the journal (i.e., the part of the shaft in contact with the bearing) slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe. Plain bearings, in general, are the least expensive type of bearing. They are also compact and lightweight, and they have a high load-carrying capacity. Design The design of a plain bearing depends on the type of motion the bearing must provide. The three types of motions possible are: * ''Journal'' (''friction'', ''radial'' or ''rotary'') ''bearing'': This is the most common type of p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolling-element Bearing

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding. One of the earliest and best-known rolling-element bearings are sets of logs laid on the ground with a large stone block on top. As the stone is pulled, the logs roll along the ground with little sliding friction. As each log comes out the back, it is moved to the front where the block then rolls on to it. It is possible to imitate such a bearing by placing several pens or pencils on a table and placing an item on top of them. See " bearings" for more on the historical development of bearings. A rolling element rotary bearing uses a shaft in a much larger hole, and cylinders called "rollers" tightly fill the space between t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Positioning Instruments

{{disambig ...

Positioning may refer to: * Positioning (marketing), creating an identity in the minds of a target market * Positioning theory, a theory in social psychology * Positioning (critical literacy), reader context * Positioning (telecommunications), a technology to approximate where a mobile phone temporarily resides * Grappling position, the positioning and holds of combatants engaged in grappling * Geopositioning, determining the location of an object in space See also * Position (other) * Real-time locating Real-time locating systems (RTLS), also known as real-time tracking systems, are used to automatically identify and track the location of objects or people in real time, usually within a building or other contained area. Wireless RTLS tags are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scientific Equipment

A scientific instrument is a device or tool used for scientific purposes, including the study of both natural phenomena and theoretical research. History Historically, the definition of a scientific instrument has varied, based on usage, laws, and historical time period. Before the mid-nineteentcenturysuch tools were referred to as "natural philosophical" or "philosophical" apparatus and instruments, and older tools from antiquity to the Middle Ages (such as the astrolabe and pendulum clock) defy a more modern definition of "a tool developed to investigate nature qualitatively or quantitatively." Scientific instruments were made by instrument makers living near a center of learning or research, such as a university or research laboratory. Instrument makers designed, constructed, and refined instruments for purposes, but if demand was sufficient, an instrument would go into production as a commercial product. In a description of the use of the eudiometer by Jan Ingenhousz to show ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |