|

Rolls-Royce C Range Engines

The Rolls-Royce ''C range'' was a series of in-line 4, 6 and 8 cylinder diesel engines used in small railway locomotives, construction vehicles, marine and similar applications. They were manufactured by the Rolls-Royce Oil Engine Division headed by W. A. Robotham to 1963, initially at Derby and later at Shrewsbury, from the 1950s through to 1970s. Although officially termed the ''C range'', they were best known for the most common C6SFL six-cylinder variant. Most had an output of around 200 bhp, with 233 bhp for the final models. Their construction was a conventional water-cooled vertical inline 6 four-stroke diesel engine of . Most were supercharged by a Roots blower, but there were also variants with a turbocharger or naturally aspirated. A later addition to the range was the SF65C model. This was a lower-rated version of the ''C'' range 6-cylinder engine and shared many of the advantages of the range's component rationalisation. It was available in naturally a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolls-Royce Limited

Rolls-Royce was a British luxury car and later an aero-engine manufacturing business established in 1904 in Manchester by the partnership of Charles Rolls and Henry Royce. Building on Royce's good reputation established with his cranes, they quickly developed a reputation for superior engineering by manufacturing the "best car in the world". The business was incorporated as Rolls-Royce Limited in 1906, and a new factory in Derby was opened in 1908. The First World War brought the company into manufacturing aero-engines. Joint development of jet engines began in 1940, and they entered production. Rolls-Royce has built an enduring reputation for development and manufacture of engines for defence and civil aircraft. In the late 1960s, Rolls-Royce was adversely affected by the mismanaged development of its advanced RB211 jet engine and consequent cost over-runs, though it ultimately proved a great success. In 1971, the owners were obliged to liquidate their business. The useful p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wet Liner

In an internal combustion engine, the engine block is the structure which contains the cylinders and other components. In an early automotive engine, the engine block consisted of just the cylinder block, to which a separate crankcase was attached. Modern engine blocks typically have the crankcase integrated with the cylinder block as a single component. Engine blocks often also include elements such as coolant passages and oil galleries. The term "cylinder block" is often used interchangeably with "engine block", although technically, the block of a modern engine (i.e. multiple cylinders integrated with another component) would be classified as a monobloc. __TOC__ Construction The main structure of an engine typically consists of the cylinders, coolant passages, oil galleries, crankcase, and cylinder head(s). The first production engines of the 1880s to 1920s usually used separate components for each of these elements, which were bolted together during engine assembly. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chain Drive

Chain drive is a way of transmitting mechanical power from one place to another. It is often used to convey power to the wheels of a vehicle, particularly bicycles and motorcycles. It is also used in a wide variety of machines besides vehicles. Most often, the power is conveyed by a roller chain, known as the drive chain or transmission chain, passing over a sprocket gear, with the teeth of the gear meshing with the holes in the links of the chain. The gear is turned, and this pulls the chain putting mechanical force into the system. Another type of drive chain is the Morse chain, invented by the Morse Chain Company of Ithaca, New York, United States. This has inverted teeth. Sometimes the power is output by simply rotating the chain, which can be used to lift or drag objects. In other situations, a second gear is placed and the power is recovered by attaching shafts or hubs to this gear. Though drive chains are often simple oval loops, they can also go around corners by placi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Prime Mover (locomotive)

In engineering, a prime mover is an engine that converts fuel to useful work. In locomotives, the prime mover is thus the source of power for its propulsion. In an engine-generator set, the engine is the prime mover, as distinct from the generator. Definition In a diesel-mechanical locomotive, the prime mover is the diesel engine that is mechanically coupled to the driving wheels (drivers). In a diesel-electric locomotive, the prime mover is the diesel engine that rotates the main generator responsible for producing electricity to power the traction motors that are geared to the drivers. The prime mover can also be a gas turbine instead of a diesel engine. In either case, the generator, traction motors and interconnecting apparatus are considered to be the power transmission system and not part of the prime mover. A wired-electric or battery-electric locomotive has no on-board prime mover, instead relying on an external power station. Weight distribution The power unit rep ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam Locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, oil or, rarely, wood) to heat water in the locomotive's boiler to the point where it becomes gaseous and its volume increases 1,700 times. Functionally, it is a steam engine on wheels. In most locomotives, the steam is admitted alternately to each end of its cylinders, in which pistons are mechanically connected to the locomotive's main wheels. Fuel and water supplies are usually carried with the locomotive, either on the locomotive itself or in a tender coupled to it. Variations in this general design include electrically-powered boilers, turbines in place of pistons, and using steam generated externally. Steam locomotives were first developed in the United Kingdom during the early 19th century and used for railway transport until the middle of the 20th century. Richard Trevithick ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam Wagon

A steam wagon (or steam lorry, steam waggon or steamtruck) is a steam-powered truck for carrying freight. It was the earliest form of lorry (truck) and came in two basic forms: ''overtype'' and ''undertype'', the distinction being the position of the engine relative to the boiler. Manufacturers tended to concentrate on one form or the other. Steam wagons were a widespread form of powered road traction for commercial haulage in the early part of the twentieth century, although they were a largely British phenomenon, with few manufacturers outside Great Britain. Competition from internal-combustion-powered vehicles and adverse legislation meant that few remained in commercial use beyond the Second World War. Although the majority of steam wagons have been scrapped, a significant number have been preserved in working order and may be seen in operation at steam fairs, particularly in the UK. Design features The steam wagon came in two basic forms. The ''overtype'' designs looked li ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sentinel Waggon Works

Sentinel Waggon Works Ltd was a British company based in Shrewsbury, Shropshire that made steam-powered lorries (steam wagons), railway locomotives, and later, diesel engined lorries, buses and locomotives. History Alley & MacLellan, Sentinel Works, Jessie Street Glasgow Alley & MacLellan was founded in 1875 and was based in Polmadie, Glasgow. This company continued in operation until the 1950s. Initially manufacturing valves and compressors for steam engines, and later whole steamships, Alley & MacLellan acquired Simpson and Bibby of Horsehay, Shropshire, manufacturer of steam-powered road vehicles, in 1903. They began producing steam road vehicles in 1905 and in 1906 introduced a five-ton vertical-boiler steam wagon, which featured a two-cylinder undertype engine and chain drive. Around 1915, Alley & McLellan moved the steam wagon production to a new factory to Shrewsbury and it continued under a separate company (see below), and in 1918 the company also opened a th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Williton MSC DH16 Front

Williton is a large village and civil parish in Somerset, England, at the junction of the A39, A358 and B3191 roads, on the coast south of Watchet between Minehead, Bridgwater and Taunton in the Somerset West and Taunton district. Williton station is on the West Somerset Railway line. Doniford Halt on the same line serves the nearby Haven Holiday centre. Williton is twinned with Neung-sur-Beuvron in the Loir-et-Cher département of France. History Until 1902 Williton was part of the ancient parish of Saint Decuman, which included also the town of Watchet. The parish of St Decuman was part of the Williton and Freemanners Hundred. Within Williton parish, to the south-west, is Orchard Wyndham House, a Grade I listed building, which was the centre of an estate called "Orchard". Paleolithic, mesolithic and neolithic flints have been found at Doniford to the north-east of Williton while three Bronze Age barrows survive at Battlegore Burial Chamber, just north of the centre of W ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel-hydraulic Locomotive

A diesel locomotive is a type of railway locomotive in which the prime mover is a diesel engine. Several types of diesel locomotives have been developed, differing mainly in the means by which mechanical power is conveyed to the driving wheels. Early internal combustion locomotives and railcars used kerosene and gasoline as their fuel. Rudolf Diesel patented his first compression-ignition engine in 1898, and steady improvements to the design of diesel engines reduced their physical size and improved their power-to-weight ratios to a point where one could be mounted in a locomotive. Internal combustion engines only operate efficiently within a limited power band, and while low power gasoline engines could be coupled to mechanical transmissions, the more powerful diesel engines required the development of new forms of transmission. This is because clutches would need to be very large at these power levels and would not fit in a standard -wide locomotive frame, or wear too quickl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Torsional Damper

A harmonic damper is a device fitted to the free (accessory drive) end of the crankshaft of an internal combustion engine to counter torsional and resonance vibrations from the crankshaft. This device must be interference fit to the crankshaft in order to operate in an effective manner. An interference fit ensures the device moves in perfect step with the crankshaft. It is essential on engines with long crankshafts (such as straight-six or straight-eight engines) and V8 engines with cross plane cranks, or V6 and straight-three engines with uneven firing order. Harmonics and torsional vibrations can greatly reduce crankshaft life, or cause instantaneous failure if the crankshaft runs at or through an amplified resonance. Dampers are designed with a specific weight (mass) and diameter, which are dependent on the damping material/method used, to reduce mechanical Q factor, or damp, crankshaft resonances. A harmonic balancer (sometimes called crankshaft damper, torsional damper, or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

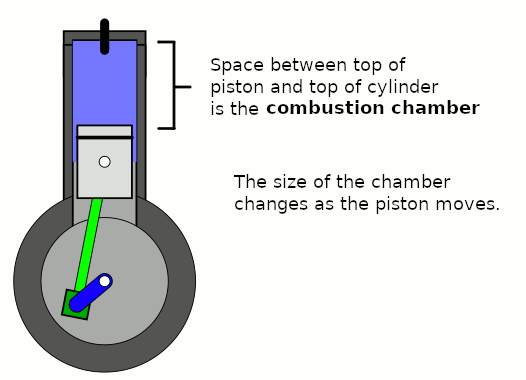

Combustion Chamber

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process. Internal combustion engines In an internal combustion engine, the pressure caused by the burning air/fuel mixture applies direct force to part of the engine (e.g. for a piston engine, the force is applied to the top of the piston), which converts the gas pressure into mechanical energy (often in the form of a rotating output shaft). This contrasts an external combustion engine, where the combustion takes place in a separate part of the engine to where the gas pressure is converted into mechanical energy. Spark-ignition engines In spark ignition engines, such as petrol (gasoline) engines, the combustion chamber is usually located in the cylinder head. The engines are often designed such that the bottom of combustion chamber is roughly in li ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Injection

Fuel injection is the introduction of fuel in an internal combustion engine, most commonly automotive engines, by the means of an injector. This article focuses on fuel injection in reciprocating piston and Wankel rotary engines. All compression-ignition engines (e.g. diesel engines), and many spark-ignition engines (i.e. petrol engines, such as Otto or Wankel), use fuel injection of one kind or another. Mass-produced diesel engines for passenger cars (such as the Mercedes-Benz OM 138) became available in the late 1930s and early 1940s, being the first fuel-injected engines for passenger car use. In passenger car petrol engines, fuel injection was introduced in the early 1950s and gradually gained prevalence until it had largely replaced carburettors by the early 1990s. The primary difference between carburetion and fuel injection is that fuel injection atomizes the fuel through a small nozzle under high pressure, while a carburettor relies on suction created by intake ai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)