|

Retarder (mechanical Engineering)

A retarder is a device used to augment or replace some of the functions of primary friction-based braking systems, usually on heavy vehicles. Retarders serve to slow vehicles, or maintain a steady speed while traveling down a hill, and help prevent the vehicle from "running away" by accelerating down the hill. They are not usually capable of bringing vehicles to a standstill, as their effectiveness diminishes as vehicle speed lowers. They are usually used as an additional "assistance" to slow vehicles, with the final braking done by a conventional friction braking system. As the friction brake will be used less, particularly at higher speeds, their service life is increased, and since in those vehicles the brakes are air-actuated helps to conserve air pressure too. Friction-based braking systems are susceptible to " brake fade" when used extensively for continuous periods, which can be dangerous if braking performance drops below what is required to stop the vehicle – for in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Petrol Engine

A petrol engine (gasoline engine in American English) is an internal combustion engine designed to run on petrol (gasoline). Petrol engines can often be adapted to also run on fuels such as liquefied petroleum gas and ethanol blends (such as ''E10'' and ''E85''). Most petrol engines use spark ignition, unlike diesel engines which typically use compression ignition. Another key difference to diesel engines is that petrol engines typically have a lower compression ratio. Design Thermodynamic cycle Most petrol engines use either the four-stroke Otto cycle or the two-stroke cycle. Petrol engines have also been produced using the Miller cycle and Atkinson cycle. Layout Most petrol-powered piston engines are straight engines or V engines. However, flat engines, W engines and other layouts are sometimes used. Wankel engines are classified by the number of rotors used. Compression ratio Cooling Petrol engines are either air-cooled or water-cooled. Ignition Pe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drag (physics)

In fluid dynamics, drag (sometimes called air resistance, a type of friction, or fluid resistance, another type of friction or fluid friction) is a force acting opposite to the relative motion of any object moving with respect to a surrounding fluid. This can exist between two fluid layers (or surfaces) or between a fluid and a solid surface. Unlike other resistive forces, such as dry friction, which are nearly independent of velocity, the drag force depends on velocity. Drag force is proportional to the velocity for low-speed flow and the squared velocity for high speed flow, where the distinction between low and high speed is measured by the Reynolds number. Even though the ultimate cause of drag is viscous friction, turbulent drag is independent of viscosity. Drag forces always tend to decrease fluid velocity relative to the solid object in the fluid's path. Examples Examples of drag include the component of the net aerodynamic or hydrodynamic force acting opposite to the d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Viscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water. Viscosity quantifies the internal frictional force between adjacent layers of fluid that are in relative motion. For instance, when a viscous fluid is forced through a tube, it flows more quickly near the tube's axis than near its walls. Experiments show that some stress (such as a pressure difference between the two ends of the tube) is needed to sustain the flow. This is because a force is required to overcome the friction between the layers of the fluid which are in relative motion. For a tube with a constant rate of flow, the strength of the compensating force is proportional to the fluid's viscosity. In general, viscosity depends on a fluid's state, such as its temperature, pressure, and rate of deformation. However, the dependence on some of these properties is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin ''valva'', the moving part of a door, in turn from ''volvere'', to turn, roll. The simplest, and very ancient, valve is simply a freely hinged flap which swings down to obstruct fluid (gas or liquid) flow in one direction, but is pushed up by the flow itself when the flow is moving in the opposite direction. This is called a check valve, as it prevents or "checks" the flow in one direction. Modern control valves may regulate pressure or flow downstream and operate on sophisticated automation systems. Valves have many uses, including controlling water for irrigation, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust System

An exhaust system is used to guide reaction exhaust gases away from a controlled combustion inside an engine or stove. The entire system conveys burnt gases from the engine and includes one or more exhaust pipes. Depending on the overall system design, the exhaust gas may flow through one or more of: *Cylinder head and exhaust manifold *A turbocharger to increase engine power. *A catalytic converter to reduce air pollution. *A muffler (North America) / silencer (UK/India), to reduce noise. Design criteria An exhaust pipe must be carefully designed to carry toxic and/or noxious gases away from the users of the machine. Indoor generators and furnaces can quickly fill an enclosed space with poisonous exhaust gases such as hydrocarbons, carbon monoxide and nitrogen oxides, if they are not properly vented to the outdoors. Also, the gases from most types of machines are very hot; the pipe must be heat-resistant, and it must not pass through or near anything that can burn or c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

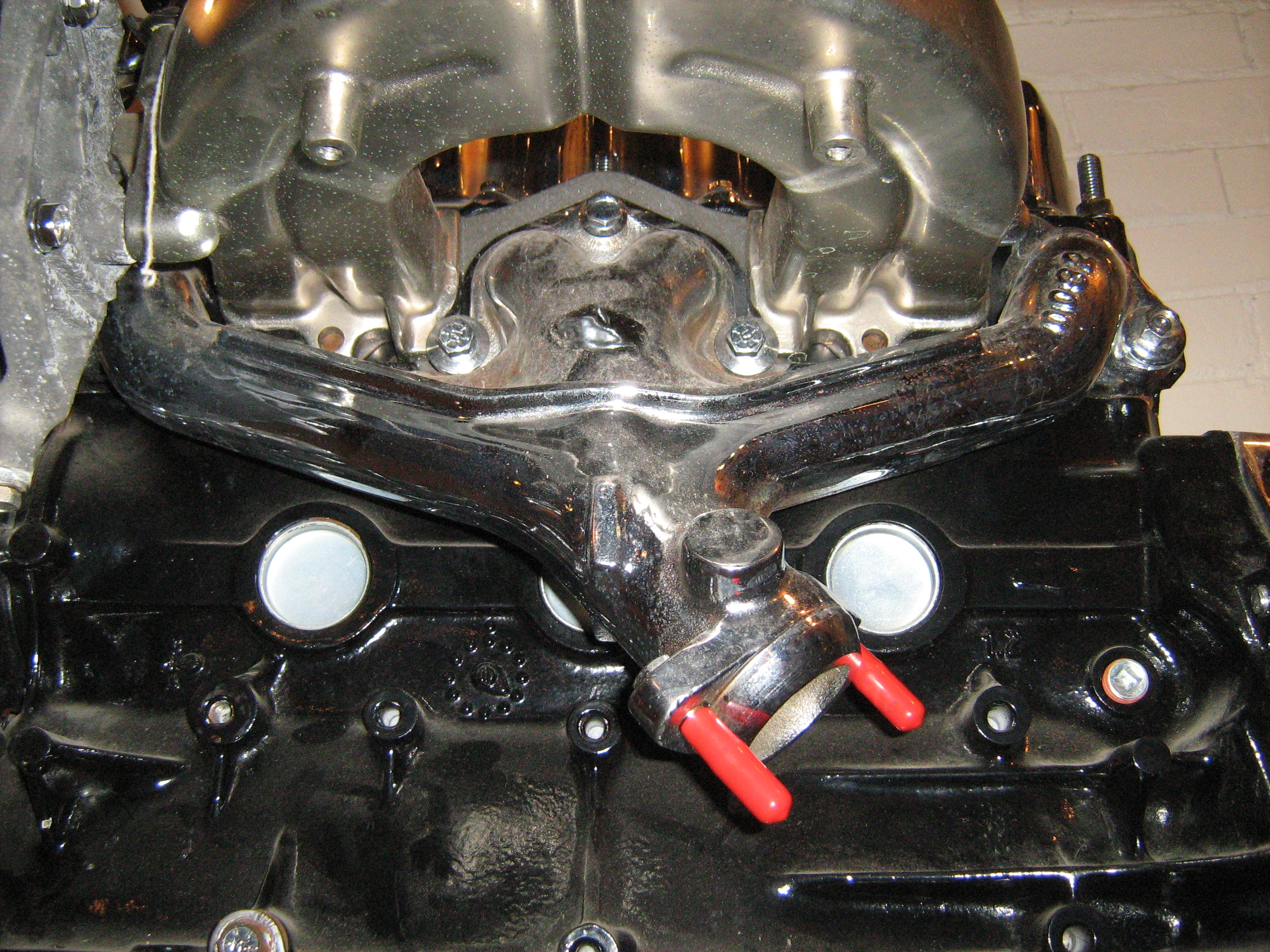

Exhaust Brakes

An exhaust brake is a means of slowing a diesel engine by closing off the exhaust path from the engine, causing the exhaust gases to be compressed in the exhaust manifold, and in the cylinder. Since the exhaust is being compressed, and there is no fuel being applied, the engine slows down the vehicle. The amount of negative torque generated is usually directly proportional to the back pressure of the engine. An exhaust brake is a device that essentially creates a major restriction in the exhaust system, and creates substantial exhaust back pressure to retard engine speed and offer some supplemental braking. In most cases, an exhaust brake is so effective that it can slow a heavily loaded vehicle on a downgrade without ever applying the vehicle's service brakes. Exhaust brakes are manufactured by many companies. The brakes vary in design, but essentially operate as described above. More advanced exhaust brakes have exhaust pressure modulation (EPM) that controls the back pressure wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compression Release Engine Brake

A compression release engine brake, compression brake, or decompression brake, frequently called a Jacobs brake or Jake Brake, is an engine braking mechanism installed on some diesel engines. When activated, it opens exhaust valves to the cylinders, right before the compression stroke ends, releasing the compressed gas trapped in the cylinders, and slowing the vehicle. Clessie Cummins was granted a patent for the engine compression brake in 1965, and the first company to manufacture them was Jacobs Vehicle Systems. The terms ''Jacobs brake'' and ''Jake Brake'' properly refer to compression brakes manufactured by Jacobs, though the terms have now become generic trademarks, and are often used to refer to compression brakes in general, especially on large vehicles and heavy equipment. Function When the driver releases the accelerator on a moving vehicle powered by an internal combustion engine, the vehicle's forward momentum continues to turn the engine's crankshaft. Most diesel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |

Transmission (mechanics)

Propulsion transmission is the mode of transmitting and controlling propulsion power of a machine. The term ''transmission'' properly refers to the whole drivetrain, including clutch, gearbox, prop shaft (for rear-wheel drive vehicles), differential, and final drive shafts. In the United States the term is sometimes used in casual speech to refer more specifically to the gearbox alone, and detailed usage differs. The transmission reduces the higher engine speed to the slower wheel speed, increasing torque in the process. Transmissions are also used on pedal bicycles, fixed machines, and where different rotational speeds and torques are adapted. Often, a transmission has multiple gear ratios (or simply "gears") with the ability to switch between them as the speed varies. This switching may be done manually (by the operator) or automatically (by a control unit). Directional (forward and reverse) control may also be provided. Single-ratio transmissions also exist, which simply ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air Compressor

An air compressor is a pneumatic device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. When the tank's pressure reaches its engineered upper limit, the air compressor shuts off. The compressed air, then, is held in the tank until called into use. The kinetic energy provided by the compressed air can be used for a variety of applications such as pneumatic tool as it is released air and the tank depressurizes. When tank pressure reaches its lower limit, the air compressor turns on again and re-pressurizes the tank. An air compressor must be differentiated from a pump because it works for any gas/air, while pumps work on a liquid. Classification Compressors may be classified according to the pressure delivered: # Low-pressure air compressors (LPACs), which have ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder (engine)

In a reciprocating engine, the cylinder is the space in which a piston travels. The inner surface of the cylinder is formed from either a thin metallic liner (also called "sleeve") or a surface coating applied to the engine block. A piston is seated inside each cylinder by several metal piston rings, which also provide seals for compression and the lubricating oil. The piston rings do not actually touch the cylinder walls, instead they ride on a thin layer of lubricating oil. Steam engines The cylinder in a steam engine is made pressure-tight with end covers and a piston; a valve distributes the steam to the ends of the cylinder. Cylinders were cast in cast iron and later in steel. The cylinder casting can include other features such as valve ports and mounting feet. Internal combustion engines The cylinder is the space through which the piston travels, propelled to the energy generated from the combustion of the air/fuel mixture in the combustion chamber. In an air ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.png)