|

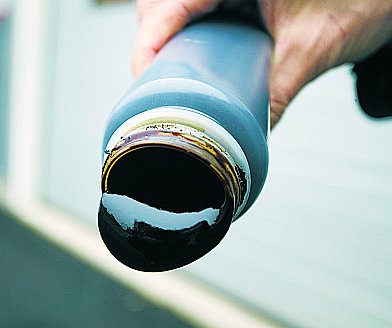

Recovery Boiler

Recovery boiler is the part of kraft process of pulping where chemicals for white liquor are recovered and reformed from black liquor, which contains lignin from previously processed wood. The black liquor is burned, generating heat, which is usually used in the process of making electricity, much as in a conventional steam power plant. The invention of the recovery boiler by G.H. Tomlinson in the early 1930s was a milestone in the advancement of the kraft process. Recovery boilers are also used in the (less common) sulfite process of wood pulping; this article deals only with recovery boiler use in the kraft process. Function of recovery boilers Concentrated black liquor contains organic dissolved wood residue in addition to sodium sulfate from the cooking chemicals added at the digester. Combustion of the organic portion of chemicals produces heat. In the recovery boiler, heat is used to produce high pressure steam, which is used to generate electricity in a turbine. The turb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kraft Process

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood chips with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na2S), known as white liquor, that breaks the bonds that link lignin, hemicellulose, and cellulose. The technology entails several steps, both mechanical and chemical. It is the dominant method for producing paper. In some situations, the process has been controversial because kraft plants can release odorous products and in some situations produce substantial liquid wastes. The process name is derived from German word ''Kraft'', meaning "strength" in this context, due to the strength of the kraft paper produced using this process. History A precursor of the Kraft process was used during the Napoleonic Wars in England. The kraft process (so called because o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flue Gases

Flue gas is the gas exiting to the atmosphere via a flue, which is a pipe or channel for conveying exhaust gases from a fireplace, oven, furnace, boiler or steam generator. Quite often, the flue gas refers to the combustion exhaust gas produced at power plants. Its composition depends on what is being burned, but it will usually consist of mostly nitrogen (typically more than two-thirds) derived from the combustion of air, carbon dioxide (), and water vapor as well as excess oxygen (also derived from the combustion air). It further contains a small percentage of a number of pollutants, such as particulate matter (like soot), carbon monoxide, nitrogen oxides, and sulfur oxides. Most fossil fuels are combusted with ambient air (as differentiated from combustion with pure oxygen). Since ambient air contains about 79 volume percent gaseous nitrogen (N2), which is essentially non-combustible, the largest part of the flue gas from most fossil-fuel combustion is uncombusted nitrogen. Car ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mitsubishi

The is a group of autonomous Japanese multinational companies in a variety of industries. Founded by Yatarō Iwasaki in 1870, the Mitsubishi Group historically descended from the Mitsubishi zaibatsu, a unified company which existed from 1870 to 1946. The company was disbanded during the occupation of Japan following World War II. The former constituents of the company continue to share the Mitsubishi brand and trademark. Although the group of companies participate in limited business cooperation, most famously through monthly "Friday Conference" executive meetings, they are formally independent and are not under common control. The four main companies in the group are MUFG Bank (the largest bank in Japan), Mitsubishi Corporation (a general trading company), Mitsubishi Electric and Mitsubishi Heavy Industries (both diversified manufacturing companies). History The Mitsubishi company was established as a shipping firm by Iwasaki Yatarō (1834–1885) in 1870 under the name ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Andritz AG

Andritz AG is an international technology group, offering plants, equipment, systems and services for various industries. The group's headquarters are in Graz, Austria. The group gets its name from the district of Andritz in which it is located and is listed on the Vienna Stock Exchange. Andritz employs more than 27,000 employees at over 280 production and service facilities. In 2020, the company reported a revenue of EUR 6.7 billion, and a net income of EUR 203.7 million. Business areas Andritz consists of 4 main business areas: *Hydro *Pulp and Paper *Metals *Separation and the business fields Feed & Biofuel Pumps Automation Andritz Metals The business area Andritz Metals (former "Rolling Mills and Strip Processing") is the third largest business unit. Andritz Metals designs, develops and erects complete lines for the production and further processing of cold-rolled carbon steel, stainless steel and non-ferrous metal strips, including furnaces, presses and acid regeneratio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metso

Metso Oyj was a Finnish industrial machinery company focusing on providing technology and services for mining, Construction aggregate, aggregates, and Petroleum industry, oil and gas, recycling, pulp and paper and other process industries. On 30 June 2020, Metso's partial demerger and combination of Metso Minerals business unit and Outotec took place. Two new companies started operations 1 July 2020: Neles and Metso Outotec. History Metso was created through the merger of Valmet and in 1999. In 2013, Metso demerged into two separate companies: Metso Corporation and Valmet Corporation. 1990s Metso was created on 1 July 1999 through the merger of Valmet, a paper and board machine supplier, and Rauma, which focused on fiber technology, rock crushing and flow control solutions. In 1998 Rauma's businesses included: * Timberjack forest machines * Sunds Defibrator fiber technology equipment * Nordberg rock crushers * Neles Controls valve-control systems The new company had over ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gasification

Gasification is a process that converts biomass- or fossil fuel-based carbonaceous materials into gases, including as the largest fractions: nitrogen (N2), carbon monoxide (CO), hydrogen (H2), and carbon dioxide (). This is achieved by reacting the feedstock material at high temperatures (typically >700 °C), without combustion, via controlling the amount of oxygen and/or steam present in the reaction. The resulting gas mixture is called syngas (from synthesis gas) or producer gas and is itself a fuel due to the flammability of the H2 and CO of which the gas is largely composed. Power can be derived from the subsequent combustion of the resultant gas, and is considered to be a source of renewable energy if the gasified compounds were obtained from biomass feedstock. An advantage of gasification is that syngas can be more efficient than direct combustion of the original feedstock material because it can be combusted at higher temperatures so that the thermodynamic upper li ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemrec

Chemrec AB (Chemrec) is a Stockholm, Sweden-based company with comprehensive experience of pioneering the development of black liquor gasification (BLG) technology for energy and chemicals recovery at pulp mills. The Chemrec process for gasification of black liquor from the chemical pulp industry offers to increase the yield of high-value energy products from 15 to 16% in modern recovery boilers to 22–23% for the BLG electricity concept (BLGCC) or to 55% for the BLG bio fuel concept (BLGMF), with 90+% green-house gas reduction. Low-cost, low-grade and abundant biomass energy then needs to be brought to the mill for a feed-stock swap to replace the gasified black liquor as feed-stock for production of steam and electricity in a biomass boiler, resulting in a total yield from added biomass to bio fuels of 70% for the BLGMF concept. Ownership history Chemrec's technology originated in the mid-1980s with an invention by Jan-Erik Kignell who was awarded the Royal Swedish Academy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kraft Process

The kraft process (also known as kraft pulping or sulfate process) is a process for conversion of wood into wood pulp, which consists of almost pure cellulose fibres, the main component of paper. The kraft process involves treatment of wood chips with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na2S), known as white liquor, that breaks the bonds that link lignin, hemicellulose, and cellulose. The technology entails several steps, both mechanical and chemical. It is the dominant method for producing paper. In some situations, the process has been controversial because kraft plants can release odorous products and in some situations produce substantial liquid wastes. The process name is derived from German word ''Kraft'', meaning "strength" in this context, due to the strength of the kraft paper produced using this process. History A precursor of the Kraft process was used during the Napoleonic Wars in England. The kraft process (so called because o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cleanability

Cleanability is a term used in clean productions (e.g. to assess the cleanability of technical surfaces). Description In order to ensure optimum cleanability of the surfaces of machines and equipment, they must fulfil certain requirements. Where surfaces come into contact with media, no deposits may be formed which could impair product quality. Therefore, the surface roughness of such areas should be below 0.8 µm (see EHEDG doc. 8). If the degree of roughness is exceeded, resistances may develop during disinfection processes. These occur when microorganisms only come into contact with disinfectants but are not killed by them. When ascertaining the cleanability of a surface with regard to particles, the analysis can be carried out in correlation with the surface cleanliness classes described in VDI 2083 Part 9.1. Surface roughness can be measured, for example, using profile methods (DIN EN ISO 11562) or AFM (atomic force microscope Atomic force microscopy (AFM) or scanning f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Char Bed

Char may refer to: People *Char Fontane, American actress *Char Margolis, American spiritualist *René Char (1907–1988), French poet *The Char family of Colombia: ** Fuad Char, Colombian senator **Alejandro Char Chaljub, mayor of Barranquilla ** Arturo Char Chaljub, Colombian senator ** David Char Navas, Colombian senator **Sofia Daccarett Char, better known as Sofia Carson, American actress and singer *Char (musician), stage name of Japanese musician Hisato Takenaka (born 1955) Other uses *River Char, a river in Dorset, England *Char (chemistry), the solid material that forms during the initial stage of combustion of a carbonaceous material *Char (fish), a common name for fishes in the genus ''Salvelinus'', including Arctic char *Char Aznable, a fictional character from the ''Mobile Suit Gundam'' series *A char in ANSI/ISO C is a value holding one byte (which was the size of a character in legacy encodings such as ASCII) *A common slang term for tea throughout the British Empir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |