|

Pulltrusion

Pultrusion is a continuous process for manufacture of fibre-reinforced plastics with constant cross-section. The term is a portmanteau word, combining "pull" and "extrusion". As opposed to extrusion, which pushes the material, pultrusion pulls the material. A very early pultrusions type patent was filed by J.H. Watson in 1944. This was followed by M.J. Meek's filing of 1950. The first commercial pultrusions were provided by Glastic Company of Cleveland, Ohio under the patent filed in 1952 by Rodger B. White. The patent issued to W. B. Goldsworthy in 1959 helped initiate the promotion and knowledge spread within the industry. W. Brandt Goldsworthy is widely regarded as the inventor of pultrusion. Parallel to the work of Goldsworthy, who concentrated his work on unsaturated polyester resins, Ernst Kühne in Germany developed a quite similar process in 1954 based on epoxy resin. Invention, development and the issuance of patents continue in the pultrusion field through today. A l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fibre-reinforced Plastic

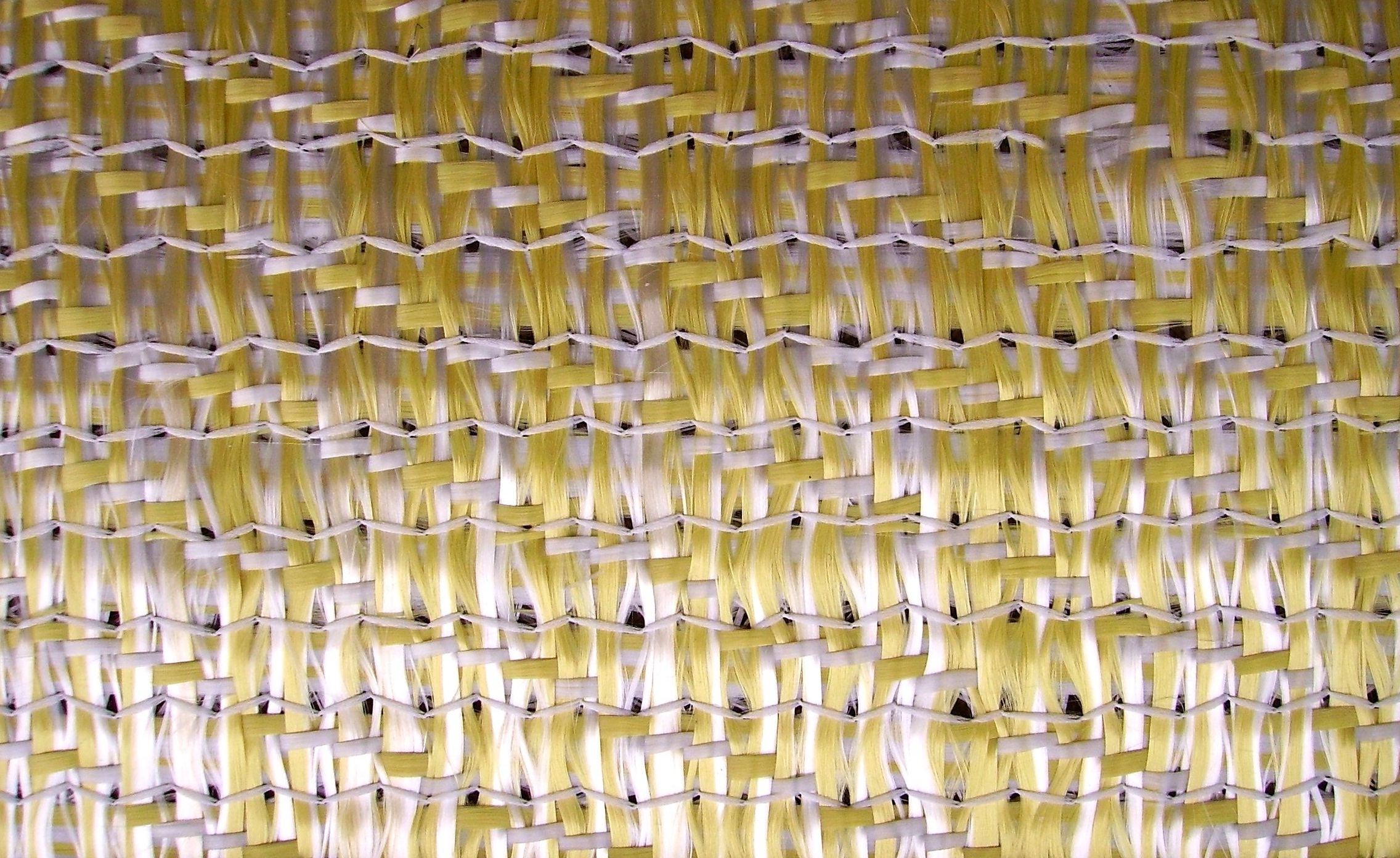

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibre-reinforced polymer), aramid, or basalt. Rarely, other fibres such as paper, wood, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, and construction industries. They are commonly found in ballistic armour and cylinders for self-contained breathing apparatuses. Process definition A polymer is generally manufactured by step-growth polymerization or addition polymerization. When combined with various agents to enhance or in any way alter the material properties of polymers, the result is referred to as a plastic. Composite plastics refers to those types of plastic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Epoxy

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called ''epoxy''. The IUPAC name for an epoxide group is an oxirane. Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (usually called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of applications, including metal coatings, composites, use in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Unit Operations

In chemical engineering and related fields, a unit operation is a basic step in a process. Unit operations involve a physical change or chemical transformation such as separation, crystallization, evaporation, filtration, polymerization, isomerization, and other reactions. For example, in milk processing, the following unit operations are involved: homogenization, pasteurization, and packaging. These unit operations are connected to create the overall process. A process may require many unit operations to obtain the desired product from the starting materials, or feedstocks. History Historically, the different chemical industries were regarded as different industrial processes and with different principles. Arthur Dehon Little developed the concept of "unit operations" to explain industrial chemistry processes in 1916. In 1923, William H. Walker, Warren K. Lewis and William H. McAdams wrote the book ''The Principles of Chemical Engineering'' and explained that the variety of ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Steps Radius-Pultrusion

A process is a series or set of activities that interact to produce a result; it may occur once-only or be recurrent or periodic. Things called a process include: Business and management *Business process, activities that produce a specific service or product for customers *Business process modeling, activity of representing processes of an enterprise in order to deliver improvements *Manufacturing process management, a collection of technologies and methods used to define how products are to be manufactured. *Process architecture, structural design of processes, applies to fields such as computers, business processes, logistics, project management *Process costing, a cost allocation procedure of managerial accounting * Process management, ensemble of activities of planning and monitoring the performance of a business process or manufacturing processes *Process management (project management), a systematic series of activities directed towards causing an end result in engineeri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flexible Pultruded Profile

Flexible may refer to: Science and technology * Power cord, a flexible electrical cable. ** Flexible cable, an Electrical cable as used on electrical appliances * Flexible electronics * Flexible response * Flexible-fuel vehicle * Flexible rake receiver * Flexible AC transmission system * Semi-flexible rod polymer * Flexible algebra, in non-associative algebras, for example alternative algebras * Flexible polyhedron * Flexible single master operation Other uses * "Flexible", a song by Depeche Mode * Flexible mold * Flextime, a variable work schedule * Flexible spending account, a tax-advantaged savings account * Flexible baton round, fired as a shotgun shell * Flxible, originally the Flexible Sidecar Co. See also * Flexibility (other) * Bendable (other) Bendable may refer to: * Articulation (other) * Bendable concrete * Bendable LED See also * * * Bend (other) Bend may refer to: Materials * Bend, a curvature in a pipe, tube, or pipelin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resource Depletion

Resource depletion is the consumption of a resource faster than it can be replenished. Natural resources are commonly divided between renewable resources and non-renewable resources (see also mineral resource classification). Use of either of these forms of resources beyond their rate of replacement is considered to be resource depletion. The value of a resource is a direct result of its availability in nature and the cost of extracting the resource, the more a resource is depleted the more the value of the resource increases. There are several types of resource depletion, the most known being: Aquifer depletion, deforestation, mining for fossil fuels and minerals, pollution or contamination of resources, slash-and-burn agricultural practices, soil erosion, and overconsumption, excessive or unnecessary use of resources. Resource depletion is most commonly used in reference to farming, fishing, mining, water usage, and consumption of fossil fuels. Depletion of wildlife popul ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyethylene Terephthalate

Polyethylene terephthalate (or poly(ethylene terephthalate), PET, PETE, or the obsolete PETP or PET-P), is the most common thermoplastic polymer resin of the polyester family and is used in fibres for clothing, containers for liquids and foods, and thermoforming for manufacturing, and in combination with glass fibre for engineering resins. In 2016, annual production of PET was 56 million tons. The biggest application is in fibres (in excess of 60%), with bottle production accounting for about 30% of global demand. In the context of textile applications, PET is referred to by its common name, polyester, whereas the acronym ''PET'' is generally used in relation to packaging. Polyester makes up about 18% of world polymer production and is the fourth-most-produced polymer after polyethylene (PE), polypropylene (PP) and polyvinyl chloride (PVC). PET consists of repeating (C10H8O4) units. PET is commonly recycled, and has the digit 1 (♳) as its resin identification code (RIC). T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polybutylene Terephthalate

Polybutylene terephthalate (PBT) is a thermoplastic engineering polymer that is used as an insulator in the electrical and electronics industries. It is a thermoplastic (semi-)crystalline polymer, and a type of polyester. PBT resists solvents, shrinks very little during forming, is mechanically strong, is heat-resistant up to (or with glass-fibre reinforcement), and can be treated with flame retardants to make it noncombustible. It was developed by Britain's Imperial Chemical Industries (ICI). PBT is closely related to other thermoplastic polyesters. Compared to PET (polyethylene terephthalate), PBT has slightly lower strength and rigidity, slightly better impact resistance, and a slightly lower glass transition temperature. PBT and PET are sensitive to hot water above (140 °F). PBT and PET need UV protection if used outdoors, and most grades of these polyesters are flammable, although additives can be used to improve both UV and flammability properties. Applications P ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoplastics

A thermoplastic, or thermosoft plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling. Most thermoplastics have a high molecular weight. The polymer chains associate by intermolecular forces, which weaken rapidly with increased temperature, yielding a viscous liquid. In this state, thermoplastics may be reshaped and are typically used to produce parts by various polymer processing techniques such as injection molding, compression molding, calendering, and extrusion. Thermoplastics differ from thermosetting polymers (or "thermosets"), which form irreversible chemical bonds during the curing process. Thermosets do not melt when heated, but typically decompose and do not reform upon cooling. Above its glass transition temperature and below its melting point, the physical properties of a thermoplastic change drastically without an associated phase change. Some thermoplastics do not fully crystallize b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermosetting Polymer

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure, or mixing with a catalyst. Heat is not necessarily applied externally, but is often generated by the reaction of the resin with a curing agent (''catalyst'', ''hardener''). Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network. The starting material for making thermosets is usually malleable or liquid prior to curing, and is often designed to be molded into the final shape. It may also be used as an adhesive. Once hardened, a thermoset cannot be melted for reshaping, in contrast to thermoplastic polymers which are commonly produced and distributed in the form of pellets, and shaped into the final product form b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vinylester

Vinyl ester resin, or often just vinyl ester, is a resin produced by the esterification of an epoxy resin with acrylic or methacrylic acids. The "vinyl" groups refer to these ester substituents, which are prone to polymerize and thus an inhibitor is usually added. The diester product is then dissolved in a reactive solvent, such as styrene, to approximately 35–45 percent content by weight. Polymerization is initiated by free radicals, which are generated by UV-irradiation or peroxides. 352px, Bis-GMA a typical "vinyl ester" derived from bisphenol A diglycidyl ether. This thermosetting polymer, thermoset material can be used as an alternative to polyester and epoxy materials as the thermoset polymer matrix in composite materials, where its characteristics, strengths, and bulk cost are intermediate between polyester and epoxy. Vinyl ester has lower resin viscosity (approx. 200 cps) than polyester (approx. 500cps) and epoxy (approx. 900cps). Uses In homebuilt airplanes, the Glas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Portmanteau

A portmanteau word, or portmanteau (, ) is a blend of wordsGarner's Modern American Usage , p. 644. in which parts of multiple words are combined into a new word, as in ''smog'', coined by blending ''smoke'' and ''fog'', or ''motel'', from ''motor'' and ''hotel''. In , a portmanteau is a single morph that is analyzed as representing two (or more) underlying s. When portmanteaus shorten es ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |