|

Process Planning

# Computer-aided process planning (CAPP) is the use of computer technology to aid in the process planning of a part or product, in manufacturing. # CAPP is the link between CAD and CAM in that it provides for the planning of the process to be used in producing a designed part. Computer-aided process planning # CAPP is a link between the CAD and CAM modules. # Process planning is concerned with determining the sequence of individual manufacturing operations needed to produce a given part or product. # The resulting operation sequence is documented on a form typically referred to as a " Route Sheet" (also called a process sheet/method sheet) containing a listing of the production operations and associated machine tools for a work part or assembly. # Process planning in manufacturing also refers to the planning of use of blanks, spare parts, packaging material, user instructions (manuals), etc. # As the term "computer-aided production planning" is used in different contexts on dif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Design

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software are helpful in protecting products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer aided design and drafting (CADD) are also used. Its use in designing electronic systems is known as '' electronic design automation'' (''EDA''). In mechanical design it is known as ''mechanical design automation'' (''MDA''), which includes the process of creating a technical drawing with the use of computer software. CAD software for mechanical design uses either vector-based graphics ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Manufacturing

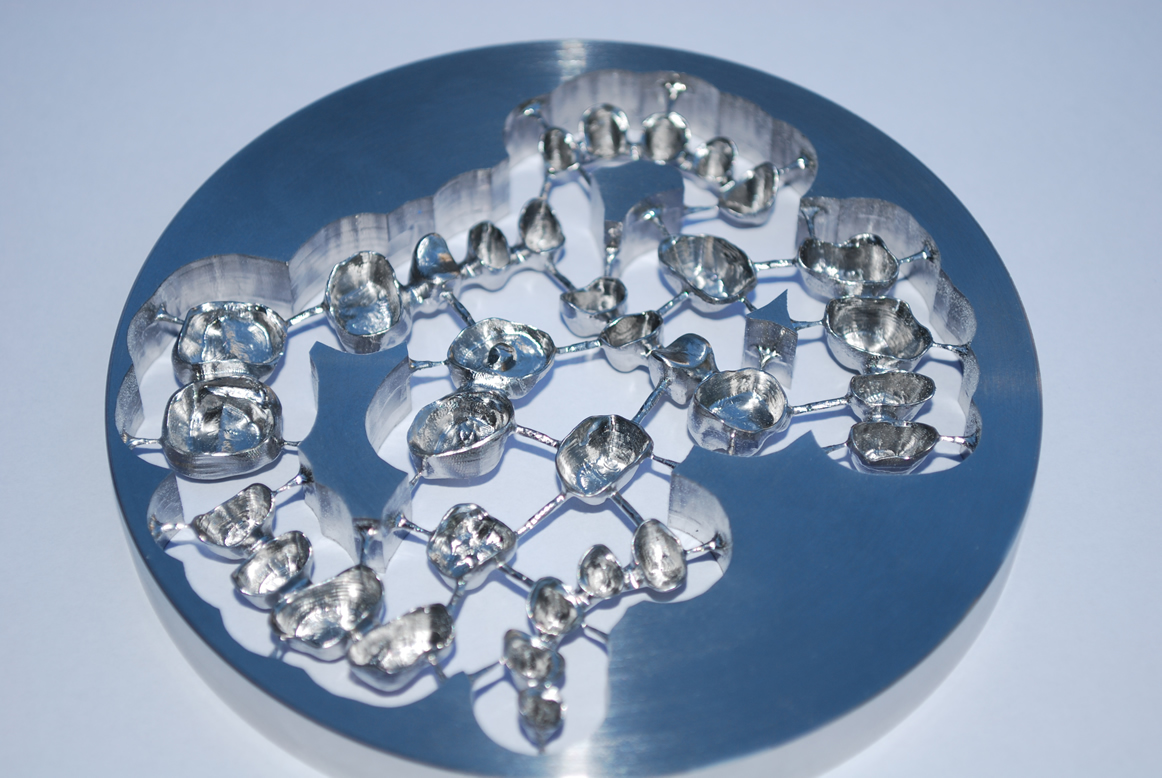

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Production Planning

Production planning is the planning of production and manufacturing modules in a company or industry. It utilizes the resource allocation of activities of employees, materials and production capacity, in order to serve different customers.Fargher, Hugh E., and Richard A. Smith. "Method and system for production planning." U.S. Patent No. 5,586,021. 17 Dec. 1996. Different types of production methods, such as single item manufacturing, batch production, mass production, continuous production etc. have their own type of production planning. Production planning can be combined with production control into production planning and control, or it can be combined with enterprise resource planning. Overview Production planning is the future of production. It can help in efficient manufacturing or setting up of a production site by facilitating required needs. A production plan is made periodically for a specific time period, called the planning horizon. It can comprise the following ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Genetic Algorithm

In computer science and operations research, a genetic algorithm (GA) is a metaheuristic inspired by the process of natural selection that belongs to the larger class of evolutionary algorithms (EA). Genetic algorithms are commonly used to generate high-quality solutions to optimization and search problems by relying on biologically inspired operators such as mutation, crossover and selection. Some examples of GA applications include optimizing decision trees for better performance, solving sudoku puzzles, hyperparameter optimization, etc. Methodology Optimization problems In a genetic algorithm, a population of candidate solutions (called individuals, creatures, organisms, or phenotypes) to an optimization problem is evolved toward better solutions. Each candidate solution has a set of properties (its chromosomes or genotype) which can be mutated and altered; traditionally, solutions are represented in binary as strings of 0s and 1s, but other encodings are also possible. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Design

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software are helpful in protecting products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer aided design and drafting (CADD) are also used. Its use in designing electronic systems is known as '' electronic design automation'' (''EDA''). In mechanical design it is known as ''mechanical design automation'' (''MDA''), which includes the process of creating a technical drawing with the use of computer software. CAD software for mechanical design uses either vector-based graphics ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Manufacturing

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-integrated Manufacturing

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control the entire production process. This integration allows individual processes to exchange information with each part. Manufacturing can be faster and less error-prone by the integration of computers. Typically CIM relies on closed-loop control processes based on real-time input from sensors. It is also known as ''flexible design and manufacturing''. Overview # Computer-integrated manufacturing is used in automotive, aviation, space, and ship building industries. # The term "computer-integrated manufacturing" is both a method of manufacturing and the name of a computer-automated system in which individual engineering, production, marketing, and support functions of a manufacturing enterprise are organized. # In a CIM system functional areas such as design, analysis, planning, purchasing, cost accounting, inventory control, and distribution are linked through the computer with facto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Lifecycle Management

In industry, Product Lifecycle Management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design and manufacture, as well as the service and disposal of manufactured products. PLM integrates people, data, processes and business systems and provides a product information backbone for companies and their extended enterprises. History The inspiration for the burgeoning business process now known as PLM came from American Motors Corporation (AMC). The automaker was looking for a way to speed up its product development process to compete better against its larger competitors in 1985, according to François Castaing, Vice President for Product Engineering and Development. Lacking the "massive budgets of General Motors, Ford, and foreign competitors … AMC placed R&D emphasis on bolstering the product lifecycle of its prime products (particularly Jeeps)." After introducing its compact Jeep Cherokee (XJ), the vehicle th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Workflow Technology

Workflow technology is a field of software products designed to improve the design of information systems. It involves use of workflow engine, also known as an orchestration engine, to execute models of processes. The models can be edited by persons not experienced in programming (e.g. managers) using workflow editors. See also * Workflow * Workflow engine * Workflow management system * Workflow application * Bioinformatics workflow management system * Scientific workflow system A scientific workflow system is a specialized form of a workflow management system designed specifically to compose and execute a series of computational or data manipulation steps, or workflow, in a scientific application. Applications Distribute ... References External links * {{Tech-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Information Technology Management

Information technology management or IT management is the discipline whereby all of the information technology resources of a firm are managed in accordance with its needs and priorities. Managing the responsibility within a company entails many of the basic management functions, like budgeting, staffing, change management, and organizing and controlling, along with other aspects that are unique to technology, like software design, network planning, tech support etc. Purpose The central aim of IT management is to generate value through the use of technology. To achieve this, business strategies and technology must be aligned. IT Management is different from management information systems. The latter refers to management methods tied to the automation or support of human decision making. IT Management refers to IT related management activities in organizations. MIS is focused mainly on the business aspect, with a strong input into the technology phase of the business/organization ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |