|

Precision Glass Moulding

Precision glass moulding is a replicative process that allows the production of high precision optical components from glass without grinding and polishing. The process is also known as ultra-precision glass pressing. It is used to manufacture precision glass lenses for consumer products such as digital cameras, and high-end products like medical systems. The main advantage over mechanical lens production is that complex lens geometries such as aspheres can be produced cost-efficiently. Process The precision glass moulding process consists of six steps:Klocke, F. et al.: "Manufacturing of glass diffractive optics by use of molding process", ''American Society for Precision Engineering (Annual Meeting)'' 21, 2006, Monterey/Calif. #The glass blank is loaded into the lower side of the moulding tool. #Oxygen is removed from the working area by filling with nitrogen and/or evacuation of the process chamber. #The tool system is nearly closed (no contact of the upper mould) and the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

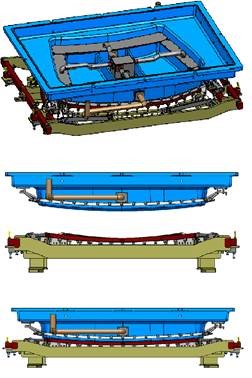

Glass Press Production Mould Tool

Glass is a non-crystalline, often transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenching) of the molten form; some glasses such as volcanic glass are naturally occurring. The most familiar, and historically the oldest, types of manufactured glass are "silicate glasses" based on the chemical compound silica (silicon dioxide, or quartz), the primary constituent of sand. Soda–lime glass, containing around 70% silica, accounts for around 90% of manufactured glass. The term ''glass'', in popular usage, is often used to refer only to this type of material, although silica-free glasses often have desirable properties for applications in modern communications technology. Some objects, such as drinking glasses and eyeglasses, are so commonly made of silicate-based glass that they are simply called by the name of the material. Despite bei ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Antireflection Coating

An antireflective, antiglare or anti-reflection (AR) coating is a type of optical coating applied to the surface of lenses, other optical elements, and photovoltaic cells to reduce reflection. In typical imaging systems, this improves the efficiency since less light is lost due to reflection. In complex systems such as cameras, binoculars, telescopes, and microscopes the reduction in reflections also improves the contrast of the image by elimination of stray light. This is especially important in planetary astronomy. In other applications, the primary benefit is the elimination of the reflection itself, such as a coating on eyeglass lenses that makes the eyes of the wearer more visible to others, or a coating to reduce the glint from a covert viewer's binoculars or telescopic sight. Many coatings consist of transparent thin film structures with alternating layers of contrasting refractive index. Layer thicknesses are chosen to produce destructive interference in the beams r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fabrication And Testing (optical Components)

Optical manufacturing and testing spans an enormous range of manufacturing procedures and optical test configurations. The manufacture of a conventional spherical lens typically begins with the generation of the optic's rough shape by grinding a glass blank. This can be done, for example, with ring tools. Next, the lens surface is polished to its final form. Typically this is done by lapping—rotating and rubbing the rough lens surface against a tool with the desired surface shape, with a mixture of abrasives and fluid in between. Typically a carved pitch tool is used to polish the surface of a lens. The mixture of abrasive is called slurry and it is typically made from cerium or zirconium oxide in water with lubricants added to facilitate pitch tool movement without sticking to the lens. The particle size in the slurry is adjusted to get the desired shape and finish. During polishing, the lens may be tested to confirm that the desired shape is being produced, and to ensure ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Precision Glass Moulding Data

Precision, precise or precisely may refer to: Science, and technology, and mathematics Mathematics and computing (general) * Accuracy and precision, measurement deviation from true value and its scatter * Significant figures, the number of digits that carry real information about a measurement * Precision and recall, in information retrieval: the proportion of relevant documents returned * Precision (computer science), a measure of the detail in which a quantity is expressed * Precision (statistics), a model parameter or a quantification of precision Computing products * Dell Precision, a line of Dell workstations * Precision Architecture, former name for PA-RISC, a reduced instruction set architecture developed by Hewlett-Packard * Ubuntu 12.04 "Precise Pangolin", Canonical's sixteenth release of Ubuntu Companies * Precision Air, an airline based in Tanzania * Precision Castparts Corp., a casting company based in Portland, Oregon, in the United States * Precision Drilling, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mould Insert Making

A mold () or mould () is one of the structures certain fungi can form. The dust-like, colored appearance of molds is due to the formation of spores containing fungal secondary metabolites. The spores are the dispersal units of the fungi. Not all fungi form molds. Some fungi form mushrooms; others grow as single cells and are called microfungi (for example yeasts). A large and taxonomically diverse number of fungal species form molds. The growth of hyphae results in discoloration and a fuzzy appearance, especially on food. The network of these tubular branching hyphae, called a mycelium, is considered a single organism. The hyphae are generally transparent, so the mycelium appears like very fine, fluffy white threads over the surface. Cross-walls (septa) may delimit connected compartments along the hyphae, each containing one or multiple, genetically identical nuclei. The dusty texture of many molds is caused by profuse production of asexual spores (conidia) formed by diffe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |