|

Plant Floor Communication

{{no footnotes, date=August 2016 Plant floor communications refers to the control and data communications typically found in automation environments, on a manufacturing plant floor or process plant. The difference between manufacturing and process is typically the types of control involved, discrete control or continuous control (aka process control). Many plants offer a hybrid of both discrete and continuous control. The underlying commonality between them all is that the automation systems are often an integration of multi-vendor products to form one system. Each vendor product typically offers communication capability for programming, maintaining and collecting data from their products. A properly orchestrated plant floor environment will likely include a variety of communications, some for machine to machine (M2M) communications – to facilitate efficient primary control over the process and some for Machine to Enterprise (M2E) communications – to facilitate connectivity ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Discrete Manufacturing

Discrete manufacturing is the production of distinct items. Automobiles, furniture, toys, smartphones, and aeroplanes are examples of discrete manufacturing products. The resulting products are easily identifiable and differ greatly from process manufacturing where the products are undifferentiated, for example oil, natural gas and salt. Discrete manufacturing is often characterized by individual or separate unit production. Units can be produced in low volume with very high complexity or high volumes of low complexity. Low volume/high complexity production results in the need for a flexible manufacturing system that can improve quality and time-to-market speed while cost cutting, cutting costs. High volume/low complexity production puts high premiums on inventory controls, lead times and reducing or limiting material costs, materials costs and waste reduction, waste. Industry Profile - Discrete Manufacturing includes makers of consumer electronics, computer and accessories, ap ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Control

An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. It is implemented widely in industries such as automotive, mining, dredging, oil refining, pulp and paper manufacturing, chemical processing and power generating plants. There is a wide range of size, type and complexity, but it enables a small number of operators to manage complex processes to a high degree of consistency. The development of large industrial process control systems was instrumental in enabling the design of large high volume and complex processes, which could not be otherwise economically or safely operated. The applications can range from controlling the temperature and level of a single process vessel, to a complete chemical processing plant with several thousand control loops. History Early process control breakthrou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automation Protocols

This is a list of communication protocols used for the automation of processes (industrial or otherwise), such as for building automation, power-system automation, automatic meter reading, and vehicular automation. Process automation protocols * AS-i – Actuator-sensor interface, a low level 2-wire bus establishing power and communications to basic digital and analog devices * BSAP – Bristol Standard Asynchronous Protocol, developed by Bristol Babcock Inc. *CC-Link Industrial Networks – Supported by the CLPA * CIP (Common Industrial Protocol) – can be treated as application layer common to DeviceNet, CompoNet, ControlNet and EtherNet/IP *ControlNet – an implementation of CIP, originally by Allen-Bradley *DeviceNet – an implementation of CIP, originally by Allen-Bradley * DF-1 - used by Allen-Bradley ControlLogix, CompactLogix, PLC-5, SLC-500, and MicroLogix class devices *DNP3 - a protocol used to communicate by industrial control and utility SCADA systems * Direct ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine To Machine

Machine to machine (M2M) is direct communication between devices using any communications channel, including wired and wireless. Machine to machine communication can include industrial instrumentation, enabling a sensor or meter to communicate the information it records (such as temperature, inventory level, etc.) to application software that can use it (for example, adjusting an industrial process based on temperature or placing orders to replenish inventory). Such communication was originally accomplished by having a remote network of machines relay information back to a central hub for analysis, which would then be rerouted into a system like a personal computer. More recent machine to machine communication has changed into a system of networks that transmits data to personal appliances. The expansion of IP networks around the world has made machine to machine communication quicker and easier while using less power. These networks also allow new business opportunities for consum ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Universal Gateway

{{unreferenced, date=January 2014 A universal gateway is a device that transacts data between two or more data sources using communication protocols specific to each. Sometimes called a universal protocol gateway, this class of product is designed as a computer appliance, and is used to connect data from one automation system to another. Typical applications Typical applications include: M2M Communications – machine to machine communications between machines from different vendors, typically using different communication protocols. This is often a requirement to optimize the performance of a production line, by effectively communicating machine states upstream and downstream of a piece of equipment. Machine idle times can trigger lower power operation. Inventory Levels can be more effectively managed on a per station basis, by knowing the upstream and downstream demands. M2E Communications – machine to enterprise communications is typically managed through database intera ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Systems Integrator

A systems integrator (or system integrator) is a person or company that specializes in bringing together component subsystems into a whole and ensuring that those subsystems function together, a practice known as system integration. They also solve problems of automation. Systems integrators may work in many fields but the term is generally used in the information technology (IT) field such as computer networking, the defense industry, the mass media, enterprise application integration, business process management or manual computer programming. Data quality issues are an important part of the work of systems integrators. Required skills A system integration engineer needs a broad range of skills and is likely to be defined by a breadth of knowledge rather than a depth of knowledge. These skills are likely to include software, systems and enterprise architecture, software and hardware engineering, interface protocols, and general problem solving skills. It is likely that the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Relational Database

A relational database is a (most commonly digital) database based on the relational model of data, as proposed by E. F. Codd in 1970. A system used to maintain relational databases is a relational database management system (RDBMS). Many relational database systems are equipped with the option of using the SQL (Structured Query Language) for querying and maintaining the database. History The term "relational database" was first defined by E. F. Codd at IBM in 1970. Codd introduced the term in his research paper "A Relational Model of Data for Large Shared Data Banks". In this paper and later papers, he defined what he meant by "relational". One well-known definition of what constitutes a relational database system is composed of Codd's 12 rules. However, no commercial implementations of the relational model conform to all of Codd's rules, so the term has gradually come to describe a broader class of database systems, which at a minimum: # Present the data to the user as relati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Systems Integrator

A systems integrator (or system integrator) is a person or company that specializes in bringing together component subsystems into a whole and ensuring that those subsystems function together, a practice known as system integration. They also solve problems of automation. Systems integrators may work in many fields but the term is generally used in the information technology (IT) field such as computer networking, the defense industry, the mass media, enterprise application integration, business process management or manual computer programming. Data quality issues are an important part of the work of systems integrators. Required skills A system integration engineer needs a broad range of skills and is likely to be defined by a breadth of knowledge rather than a depth of knowledge. These skills are likely to include software, systems and enterprise architecture, software and hardware engineering, interface protocols, and general problem solving skills. It is likely that the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Eatm

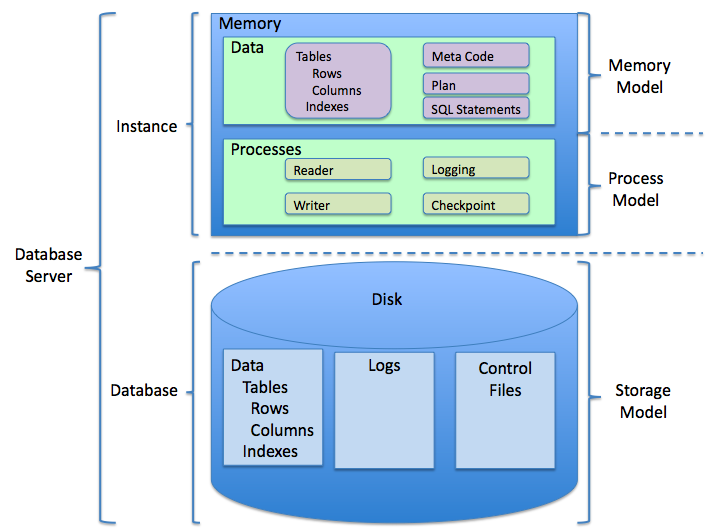

{{More citations needed, date=May 2020 An enterprise appliance transaction module (EATM) is a device, typically used in the manufacturing automation marketplace, for the transfer of plant floor equipment and product status to manufacturing execution systems (MES), enterprise resource planning (ERP) systems and the like. Solutions that deliver manufacturing floor integration have evolved over time. Initially they took the form of custom integrated systems, designed and delivered by system integrators. These solutions were largely based on separate commercial off-the-shelf (COTS) products integrated into a custom system. Modern EATM products might not needing any software development or custom integration. Components Hardware platform – embedded computer, computer appliance Device communications software – Support for the automation protocols from which data will be extracted. Device communications software typically operates through polled or change based protocols that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Automation Protocols

This is a list of communication protocols used for the automation of processes (industrial or otherwise), such as for building automation, power-system automation, automatic meter reading, and vehicular automation. Process automation protocols * AS-i – Actuator-sensor interface, a low level 2-wire bus establishing power and communications to basic digital and analog devices * BSAP – Bristol Standard Asynchronous Protocol, developed by Bristol Babcock Inc. *CC-Link Industrial Networks – Supported by the CLPA * CIP (Common Industrial Protocol) – can be treated as application layer common to DeviceNet, CompoNet, ControlNet and EtherNet/IP *ControlNet – an implementation of CIP, originally by Allen-Bradley *DeviceNet – an implementation of CIP, originally by Allen-Bradley * DF-1 - used by Allen-Bradley ControlLogix, CompactLogix, PLC-5, SLC-500, and MicroLogix class devices *DNP3 - a protocol used to communicate by industrial control and utility SCADA systems * Direct ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

OPC Foundation

The OPC Foundation (Open Platform Communications, formerly Object Linking and Embedding for Process Control) is an industry consortium that creates and maintains standards for open connectivity of industrial automation devices and systems, such as industrial control systems and process control generally. The OPC standards specify the communication of industrial process data, alarms and events, historical data and batch process data between sensors, instruments, controllers, software systems, and notification devices. The OPC Foundation started in 1994, as a task force comprising five industrial automation vendors ( Fisher-Rosemount, Rockwell Software, Opto 22, Intellution, and Intuitive Technology), with the purpose of creating a basic OLE for Process Control specification. OLE is a technology developed by Microsoft Corporation for the MS Windows operating system. The task force released the OPC standard in August 1996. The OPC Foundation was chartered to continue developme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Automation

Automation describes a wide range of technologies that reduce human intervention in processes, namely by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines. Automation has been achieved by various means including mechanical, hydraulic, pneumatic, electrical, electronic devices, and computers, usually in combination. Complicated systems, such as modern factories, airplanes, and ships typically use combinations of all of these techniques. The benefit of automation includes labor savings, reducing waste, savings in electricity costs, savings in material costs, and improvements to quality, accuracy, and precision. Automation includes the use of various equipment and control systems such as machinery, processes in factories, boilers, and heat-treating ovens, switching on telephone networks, steering, and stabilization of ships, aircraft, and other applications and vehicles with reduced human in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |