|

Peierls–Nabarro Force

Peierls stress (also known as the lattice friction stress) is the force (first described by Rudolf Peierls and modified by Frank Nabarro) needed to move a dislocation within a plane of atoms in the unit cell. The magnitude varies periodically as the dislocation moves within the plane. Peierls stress depends on the size and width of a dislocation and the distance between planes. Because of this, Peierls stress decreases with increasing distance between atomic planes. Yet since the distance between planes increases with planar atomic density, Slip (materials science), slip of the dislocation is preferred on closely packed planes. Peierls–Nabarro stress proportionality :\tau_\mathrm \propto Ge^ Where: :W = \frac= the dislocation width :G = shear modulus :\nu = Poisson's ratio :b = slip distance or Burgers vector :d = interplanar spacing The Peierls stress and yield strength temperature sensitivity The Peierls stress also relates to the temperature sensitivity of the yield ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rudolf Peierls

Sir Rudolf Ernst Peierls, (; ; 5 June 1907 – 19 September 1995) was a German-born British physicist who played a major role in Tube Alloys, Britain's nuclear weapon programme, as well as the subsequent Manhattan Project, the combined Allied nuclear bomb programme. His obituary in ''Physics Today'' described him as "a major player in the drama of the eruption of nuclear physics into world affairs". Peierls studied physics at the University of Berlin, at the University of Munich under Arnold Sommerfeld, the University of Leipzig under Werner Heisenberg, and ETH Zurich under Wolfgang Pauli. After receiving his DPhil from Leipzig in 1929, he became an assistant to Pauli in Zurich. In 1932, he was awarded a Rockefeller Fellowship, which he used to study in Rome under Enrico Fermi, and then at the Cavendish Laboratory at the University of Cambridge under Ralph H. Fowler. Because of his Jewish background, he elected to not return home after Adolf Hitler's rise to power in 1933, b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Frank Nabarro

Frank Reginald Nunes Nabarro MBE OMS FRS (7 March 1916 – 20 July 2006) was an English-born South African physicist and one of the pioneers of solid-state physics, which underpins much of 21st-century technology. Education Born 7 March 1916 in London, UK, into a Sephardi Jewish family, he studied at Nottingham High School, then at New College, Oxford where he obtained a first-class honours degree in physics in 1937 and another in mathematics in 1938. At the University of Bristol his work under Professor Nevill Francis Mott, a future Nobel Laureate in physics, earned him the Oxford degree of BSc (then equivalent to an MSc elsewhere). Then followed an M.A. in 1945. Within a few years he had risen to a leading role in the field of crystal lattice dislocations and plasticity. In this period he wrote a number of seminal papers which are still cited. Later papers and the books that he published cemented his dominance of the field. (See also Egon Orowan) Military and academic ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dislocation

In materials science, a dislocation or Taylor's dislocation is a linear crystallographic defect or irregularity within a crystal structure that contains an abrupt change in the arrangement of atoms. The movement of dislocations allow atoms to slide over each other at low stress levels and is known as ''glide'' or slip. The crystalline order is restored on either side of a ''glide dislocation'' but the atoms on one side have moved by one position. The crystalline order is not fully restored with a ''partial dislocation''. A dislocation defines the boundary between ''slipped'' and ''unslipped'' regions of material and as a result, must either form a complete loop, intersect other dislocations or defects, or extend to the edges of the crystal. A dislocation can be characterised by the distance and direction of movement it causes to atoms which is defined by the Burgers vector. Plastic deformation of a material occurs by the creation and movement of many dislocations. The number and a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Unit Cell

In geometry, biology, mineralogy and solid state physics, a unit cell is a repeating unit formed by the vectors spanning the points of a lattice. Despite its suggestive name, the unit cell (unlike a unit vector, for example) does not necessarily have unit size, or even a particular size at all. Rather, the primitive cell is the closest analogy to a unit vector, since it has a determined size for a given lattice and is the basic building block from which larger cells are constructed. The concept is used particularly in describing crystal structure in two and three dimensions, though it makes sense in all dimensions. A lattice can be characterized by the geometry of its unit cell, which is a section of the tiling (a parallelogram or parallelepiped) that generates the whole tiling using only translations. There are two special cases of the unit cell: the primitive cell and the conventional cell. The primitive cell is a unit cell corresponding to a single lattice point, it is the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slip (materials Science)

In materials science, slip is the large displacement of one part of a crystal relative to another part along crystallographic planes and directions. Slip occurs by the passage of dislocations on close/packed planes, which are planes containing the greatest number of atoms per area and in close-packed directions (most atoms per length). Close-packed planes are known as ''slip'' or ''glide planes''. A slip system describes the set of symmetrically identical slip planes and associated family of slip directions for which dislocation motion can easily occur and lead to plastic deformation. The magnitude and direction of slip are represented by the Burgers vector, . An external force makes parts of the crystal lattice glide along each other, changing the material's geometry. A critical resolved shear stress is required to initiate a slip., Hull D., Bacon, D.J (2001); "Introduction to Dislocations", 4th ed., Slip systems Face centered cubic crystals Slip in face centered cubic (f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear Modulus

In materials science, shear modulus or modulus of rigidity, denoted by ''G'', or sometimes ''S'' or ''μ'', is a measure of the elastic shear stiffness of a material and is defined as the ratio of shear stress to the shear strain: :G \ \stackrel\ \frac = \frac = \frac where :\tau_ = F/A \, = shear stress :F is the force which acts :A is the area on which the force acts :\gamma_ = shear strain. In engineering :=\Delta x/l = \tan \theta , elsewhere := \theta :\Delta x is the transverse displacement :l is the initial length of the area. The derived SI unit of shear modulus is the pascal (Pa), although it is usually expressed in gigapascals (GPa) or in thousand pounds per square inch (ksi). Its dimensional form is M1L−1T−2, replacing ''force'' by ''mass'' times ''acceleration''. Explanation The shear modulus is one of several quantities for measuring the stiffness of materials. All of them arise in the generalized Hooke's law: * Young's modulus ''E'' describes the mat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Poisson's Ratio

In materials science and solid mechanics, Poisson's ratio \nu ( nu) is a measure of the Poisson effect, the deformation (expansion or contraction) of a material in directions perpendicular to the specific direction of loading. The value of Poisson's ratio is the negative of the ratio of transverse strain to axial strain. For small values of these changes, \nu is the amount of transversal elongation divided by the amount of axial compression. Most materials have Poisson's ratio values ranging between 0.0 and 0.5. For soft materials, such as rubber, where the bulk modulus is much higher than the shear modulus, Poisson's ratio is near 0.5. For open-cell polymer foams, Poisson's ratio is near zero, since the cells tend to collapse in compression. Many typical solids have Poisson's ratios in the range of 0.2–0.3. The ratio is named after the French mathematician and physicist Siméon Poisson. Origin Poisson's ratio is a measure of the Poisson effect, the phenomenon in which a ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

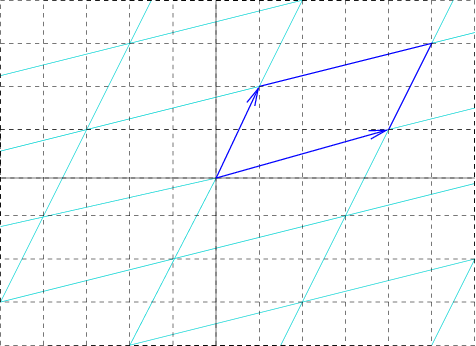

Burgers Vector

In materials science, the Burgers vector, named after Dutch physicist Jan Burgers, is a vector, often denoted as , that represents the magnitude and direction of the lattice distortion resulting from a dislocation in a crystal lattice. The vector's magnitude and direction is best understood when the dislocation-bearing crystal structure is first visualized ''without'' the dislocation, that is, the ''perfect'' crystal structure. In this perfect crystal structure, a rectangle whose lengths and widths are integer multiples of (the unit cell edge length) is drawn ''encompassing'' the site of the original dislocation's origin. Once this encompassing rectangle is drawn, the dislocation can be introduced. This dislocation will have the effect of deforming, not only the perfect crystal structure, but the rectangle as well. The said rectangle could have one of its sides disjoined from the perpendicular side, severing the connection of the length and width line segments of the rectangle at ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yield Strength

In materials science and engineering, the yield point is the point on a stress-strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as plastic deformation. The yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically. The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producing permanent deformation. In some materials, such as aluminium, there is a gradual onset of non-linear behavior, making the precise yield point difficult to determine. In such a case, the offset yiel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |