|

PCV Valve

A crankcase ventilation system removes unwanted gases from the crankcase of an internal combustion engine. The system usually consists of a tube, a one-way valve and a vacuum source (such as the inlet manifold). The unwanted gases, called "blow-by", are gases from the combustion chamber which have leaked past the piston rings. Early engines released these gases to the atmosphere simply by them leaking through the crankcase seals. The first specific crankcase ventilation system was the ''road draught tube'', which used a partial vacuum to draw the gases through a tube and release them to the atmosphere. Positive crankcase ventilation (PCV) systems— first used in the Second World War and present on most modern engines— send the crankcase gases back to the combustion chamber, in order to reduce air pollution. Two-stroke engines with a crankcase compression design do not need a crankcase ventilation system, because normal operation of the engine involves sending the crankcase gas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PCV System

PCV may refer to: Biology and medicine * Packed cell volume, a clinical test * Palm Creek virus, a virus * Polycythemia vera, a disease * Polypoidal choroidal vasculopathy, an eye disease * Procarbazine/CCNU/vincristine, a chemotherapy regimen for brain tumors * Pneumococcal conjugate vaccine * Porcine circovirus, a virus * ''Plasma cell variant'' of Castleman disease *Penicillin V, a type of antibiotic Transportation * Passenger Carrying Vehicle * Propelling Control Vehicle, British railway coach for carrying mail * Positive crankcase ventilation, of an internal combustion engine Organisations * Presbyterian Church of Victoria, Australia * Presbyterian Church of Vanuatu * Communist Party of Venezuela (''Partido Comunista de Venezuela''), a communist party in Venezuela Other uses * Product category volume, weighted measure of distribution based on store sales within the product category * Police Community Volunteer, UK * Peace Corps Volunteer, of the Peace Corps The Peace ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Venturi Tube

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section (or choke) of a pipe. The Venturi effect is named after its discoverer, the 18th century Italian physicist, Giovanni Battista Venturi. Background In inviscid fluid dynamics, an incompressible fluid's velocity must ''increase'' as it passes through a constriction in accord with the principle of mass continuity, while its static pressure must ''decrease'' in accord with the principle of conservation of mechanical energy ( Bernoulli's principle). Thus, any gain in kinetic energy a fluid may attain by its increased velocity through a constriction is balanced by a drop in pressure. By measuring pressure, the flow rate can be determined, as in various flow measurement devices such as Venturi meters, Venturi nozzles and orifice plates. Referring to the adjacent diagram, using Bernoulli's equation in the special case of steady, incompressible, inviscid flows (such ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dry Sump

A dry-sump system is a method to manage the lubricating motor oil in four-stroke and large two-stroke piston driven internal combustion engines. The dry-sump system uses two or more oil pumps and a separate oil reservoir, as opposed to a conventional wet-sump system, which uses only the main sump (U.S.: oil pan) below the engine and a single pump. A dry-sump engine requires a pressure relief valve to regulate negative pressure inside the engine, so internal seals are not inverted. Dry-sumps are common on larger diesel engines such as those used in ships, as well as gasoline engines used in racing cars, aerobatic aircraft, high-performance personal watercraft and motorcycles. Dry sump lubrication may be chosen for these applications due to increased reliability, oil capacity, reduction of oil starvation under high g-loads and/or other technical or performance reasons. Dry sump systems may not be suitable for all applications due to increased cost, complexity, and/or bulk, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

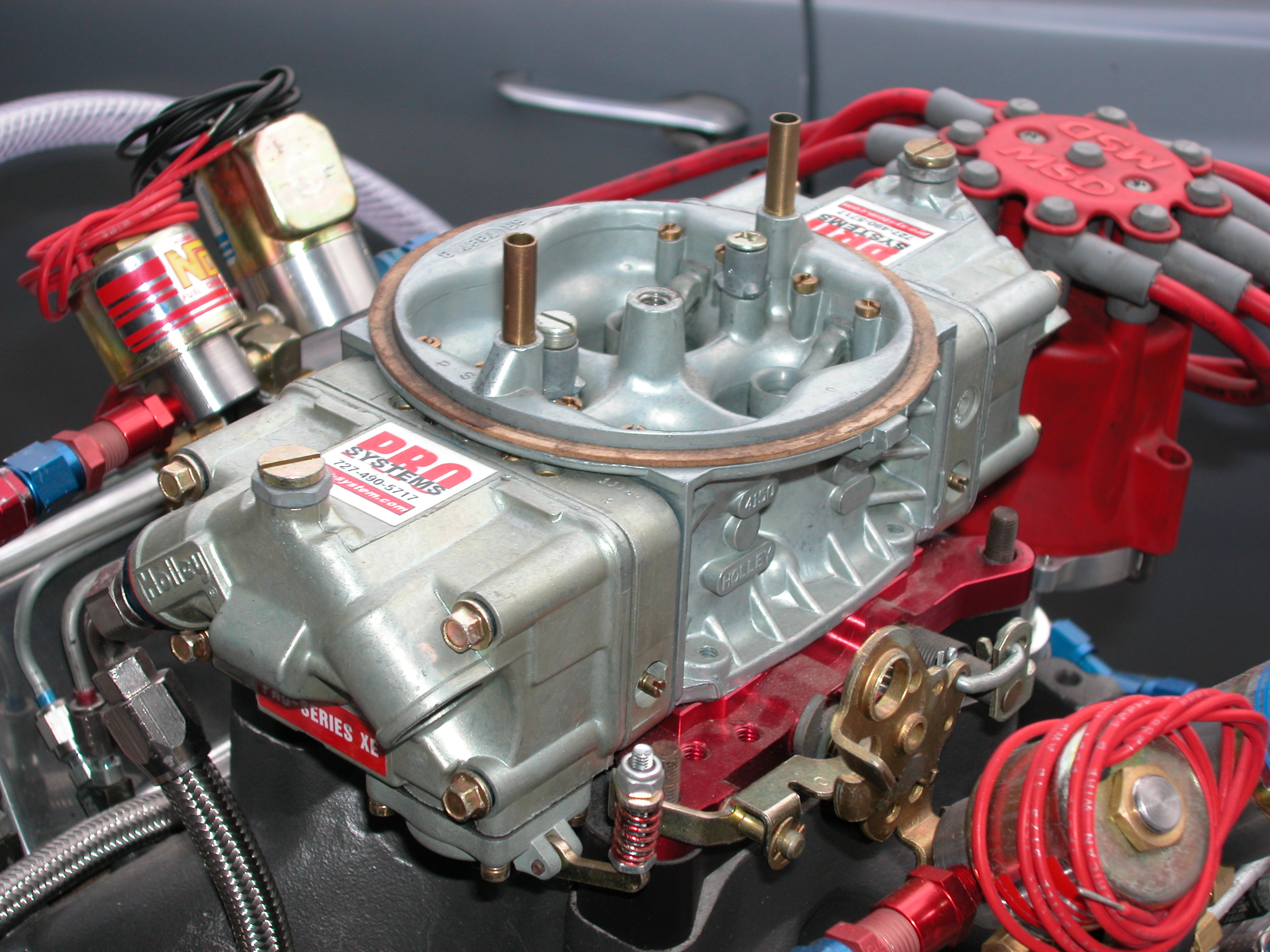

Carburetor

A carburetor (also spelled carburettor) is a device used by an internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the venturi tube in the main metering circuit, however various other components are also used to provide extra fuel or air in specific circumstances. Since the 1990s, carburetors have been largely replaced by fuel injection for cars and trucks, however carburetors are still used by some small engines (e.g. lawnmowers, generators and concrete mixers) and motorcycles. Diesel engines have always used fuel injection instead of carburetors. Etymology The name "carburetor" is derived from the verb ''carburet'', which means "to combine with carbon," or in particular, "to enrich a gas by combining it with carbon or hydrocarbons." Thus a carburetor mixes intake air with hydrocarbon-based fuel, such as petrol or autogas (LPG). The name is spelled "carburetor" in American Eng ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankcase

In a piston engine, the crankcase is the housing that surrounds the crankshaft. In most modern engines, the crankcase is integrated into the engine block. Two-stroke engines typically use a crankcase-compression design, resulting in the fuel/air mixture passing through the crankcase before entering the cylinder(s). This design of the engine does not include an oil sump in the crankcase. Four-stroke engines typically have an oil sump at the bottom of the crankcase and the majority of the engine's oil is held within the crankcase. The fuel/air mixture does not pass through the crankcase in a four-stroke engine, however a small amount of exhaust gasses often enter as "blow-by" from the combustion chamber. The crankcase often forms the lower half of the main bearing journals (with the bearing caps forming the other half), although in some engines the crankcase completely surrounds the main bearing journals. An ''open-crank'' engine has no crankcase. This design was used in early ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Sludge

Oil sludge or black sludge is a gel-like or semi-solid deposit inside an internal combustion engine, that can create a catastrophic buildup. It is often the result of contaminated engine oil and occurs when moisture and/or high heat is introduced to engine oil. Causes Oil sludge may occur due to a variety of different factors. Some of the most common causes are: * Defective crankcase ventilation system * Oil/coolant contamination * Neglecting oil changes * Low oil level * Poor engine design Precautions Oil sludge is generally preventable through frequent oil changes at manufacturer specified intervals, however, while uncommon, some engines do have a tendency to build up more sludge than others. References External links burn oil sludge utilizationInstallation for saving of heavy fuel on boilers,utilization of condensate water and heavy residuals of fuel in tankfarmwaste oil Waste oil is defined as any petroleum-based or synthetic oil that, through contamination, has become ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Straight Engine

The straight or inline engine is an internal combustion engine with all cylinders aligned in one row and having no offset. Usually found in four, six and eight cylinder configurations, they have been used in automobiles, locomotives and aircraft, although the term in-line has a broader meaning when applied to aircraft engines, see Inline engine (aviation). Design A straight engine is considerably easier to build than an otherwise equivalent horizontally opposed or V engine, because both the cylinder bank and crankshaft can be milled from a single metal casting, and it requires fewer cylinder heads and camshafts. In-line engines are also smaller in overall physical dimensions than designs such as the radial, and can be mounted in any direction. Straight configurations are simpler than their V-shaped counterparts. Although six-cylinder engines are inherently balanced, the four-cylinder models are inherently off balance and rough, unlike 90-degree V fours and horizontally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

V Engine

A V engine, sometimes called a Vee engine, is a common configuration for internal combustion engines. It consists of two cylinder banks—usually with the same number of cylinders in each bank—connected to a common crankshaft. These cylinder banks are arranged at an angle to each other, so that the banks form a "V" shape when viewed from the front of the engine. V engines typically have a shorter length than equivalent inline engines, however the trade-off is a larger width. V6, V8 and V12 engines are the most common layout for automobile engines with 6, 8 or 12 cylinders respectively. History The first V engine, a two-cylinder V-twin, was designed by Wilhelm Maybach and used in the 1889 Daimler Stahlradwagen automobile. The first V8 engine was produced in 1903, in the form of the Antoinette engine designed by Léon Levavasseur for racing boats and airplanes. The first V12 engine was produced the following year by Putney Motor Works in London, again for use in rac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Back-fire

A backfire or afterburn is combustion or an explosion produced by a running internal combustion engine that occurs in the exhaust system, rather than inside the combustion chamber. It is also sometimes referred to as an afterfire, especially in cases where the word backfire is used to mean a fuel burn that occurs while an intake valve is open, causing the fire to move backward through the system and out through the intake instead of the exhaust. When the flame moves backward it may also be called a "pop-back." A backfire can be caused either by ignition that happens with an exhaust valve open or unburnt fuel making its way in the hot exhaust system. A visible flame may momentarily shoot out of the exhaust pipe. A backfire is often a sign that the engine is improperly-tuned. The term derives from parallel experiences with early unreliable firearms or ammunition in which the explosive force was directed out at the breech instead of the muzzle. That is the origin of the use of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flame Arrester

A flame arrester (also spelled arrestor), deflagration arrester, or flame trap are safety devices fitted to openings of enclosures or to pipe work, and are intended to allow flow but prevent flame transmission fuel combustion by extinguishing the flame. Usage and applications The uses of a flame arrester include: *Stopping the spread of an open fire *Limiting the spread of an already occurred explosion *Preventing potentially explosive mixtures from igniting *Confining fire within a controlled location *Stopping the propagation of a flame traveling at subsonic velocities Some common objects that have flame arresters are: * Fuel storage tank vents * Fuel gas pipelines * Safety storage cabinets for paint, aerosol cans, and other flammable mixtures * The exhaust system of internal combustion engines * The air intake of marine inboard engines * Davy lamps in coal mining * Overproof rum and other flammable liquors. * Portable plastic gasoline containers Principles Flame arrester ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Catch Tank

An oil catch tank or oil catch can is a device that is fitted into the cam/crankcase ventilation system on a car. Installing an oil catch tank (can) aims to reduce the amount of oil vapors re-circulated into the intake of the engine. Positive crankcase ventilation During normal operation of a car engine, some vapors from the cylinder pass by the piston rings and down into the crankcase. Without ventilation this can pressurize the crankcase and cause issues such as lack of piston ring sealing and damaged oil seals. To avoid this, manufacturers created a crankcase ventilation system. Originally this was often a very basic setup where a filter was placed on the top of the cam case and the pressure and vapors were vented to atmosphere. This was deemed unacceptable as it allowed fumes and oil mist to be vented out into the atmosphere which caused pollution. It could also cause issues for the occupants of the car as it could be drawn into the inside of the car, which was often unpleas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)