|

Ozone Cracking

Cracks can be formed in many different elastomers by ozone attack, and the characteristic form of attack of vulnerable rubbers is known as ozone cracking. The problem was formerly very common, especially in tires, but is now rarely seen in those products owing to preventive measures. However, it does occur in many other safety-critical items such as fuel lines and rubber seals, such as gaskets and O-rings, where ozone attack is considered unlikely. Only a trace amount of the gas is needed to initiate cracking, and so these items can also succumb to the problem. Susceptible elastomers Tiny traces of ozone in the air will attack double bonds in rubber chains, with natural rubber, polybutadiene, styrene-butadiene rubber and nitrile rubber being most sensitive to degradation. Every repeat unit in the first three materials has a double bond, so every unit can be degraded by ozone. Nitrile rubber is a copolymer of butadiene and acrylonitrile units, but the proportion of acrylonitrile ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Natural Rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds. Thailand, Malaysia, and Indonesia are three of the leading rubber producers. Types of polyisoprene that are used as natural rubbers are classified as elastomers. Currently, rubber is harvested mainly in the form of the latex from the rubber tree (''Hevea brasiliensis'') or others. The latex is a sticky, milky and white colloid drawn off by making incisions in the bark and collecting the fluid in vessels in a process called "tapping". The latex then is refined into the rubber that is ready for commercial processing. In major areas, latex is allowed to coagulate in the collection cup. The coagulated lumps are collected and processed into dry forms for sale. Natural rubber is used extensively in many applications and products, either alone or in combination wit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Acrylonitrile

Acrylonitrile is an organic compound with the formula and the structure . It is a colorless, volatile liquid although commercial samples can be yellow due to impurities. It has a pungent odor of garlic or onions. In terms of its molecular structure, it consists of a vinyl group () linked to a nitrile (). It is an important monomer for the manufacture of useful plastics such as polyacrylonitrile. It is reactive and toxic at low doses. Acrylonitrile was first synthesized by the French chemist Charles Moureu (1863–1929) in 1893. Occurrence Acrylonitrile is not naturally formed on Earth. It has been detected at the sub-ppm level at industrial sites. It persists in the air for up to a week. It decomposes by reacting with oxygen and hydroxyl radical to form formyl cyanide and formaldehyde. Acrylonitrile is harmful to aquatic life. Acrylonitrile has been detected in the atmosphere of Titan, a moon of Saturn. Computer simulations suggest that on Titan conditions exist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress Concentration

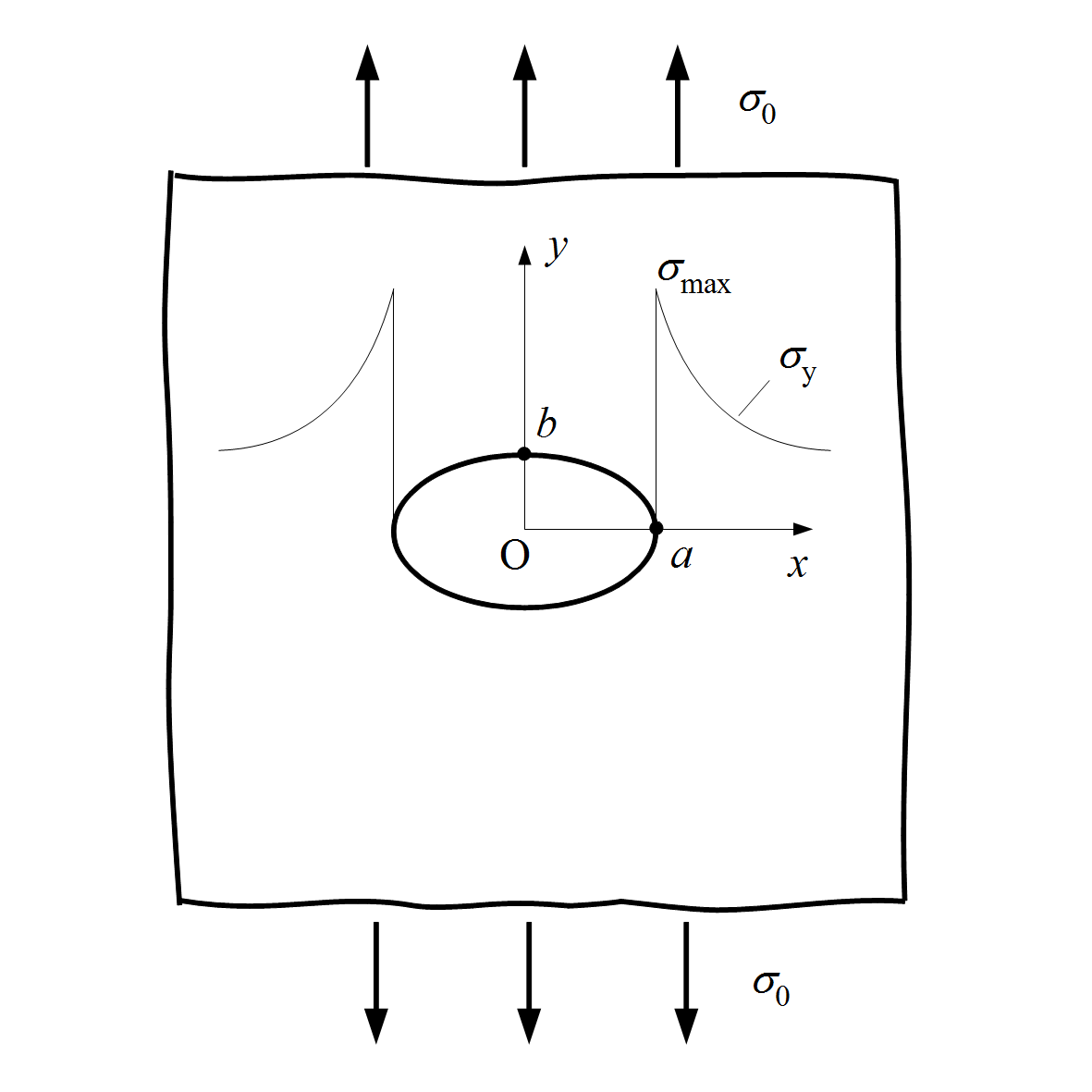

In solid mechanics, a stress concentration (also called a stress raiser or a stress riser) is a location in an object where the stress is significantly greater than the surrounding region. Stress concentrations occur when there are irregularities in the geometry or material of a structural component that cause an interruption to the flow of stress. This arises from such details as holes, grooves, notches and fillets. Stress concentrations may also occur from accidental damage such as nicks and scratches. The degree of concentration of a discontinuity under typically tensile loads can be expressed as a non-dimensional stress concentration factor K_t, which is the ratio of the highest stress to the nominal far field stress. For a circular hole in an infinite plate, K_t = 3. The stress concentration factor should not be confused with the stress intensity factor, which is used to define the effect of a crack on the stresses in the region around a crack tip. For ductile materials ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pneumatic

Pneumatics (from Greek ‘wind, breath’) is a branch of engineering that makes use of gas or pressurized air. Pneumatic systems used in Industrial sector, industry are commonly powered by compressed air or compressed inert gases. A centrally located and electrically-powered Gas compressor, compressor powers Pneumatic cylinder, cylinders, air motors, pneumatic actuators, and other pneumatic devices. A pneumatic system controlled through manual or automatic solenoid valves is selected when it provides a lower cost, more flexible, or safer alternative to electric motors, and hydraulic actuators. Pneumatics also has applications in dentistry, construction, mining, and other areas. Gases used in pneumatic systems Pneumatic systems in fixed installations, such as factories, use compressed air because a sustainable supply can be made by compressing Atmosphere of Earth, atmospheric air. The air usually has moisture removed, and a small quantity of oil is added at the compressor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diaphragm Seal

A diaphragm seal is a flexible membrane that seals and isolates an enclosure. The flexible nature of this seal allows pressure effects to cross the barrier but not the material being contained. Common uses for diaphragm seals are to protect pressure sensors from the fluid whose pressure is being measured. Materials Since diaphragm seals need to be highly flexible, elastomers are commonly used, and include a wide variety of both general purpose and speciality rubbers. Elastomers are limited to low pressure applications and those that are chemically compatible with the various plastics and rubbers used. Metal diaphragms of stainless steel (several grades), Carpenter 20, Hastelloy, Monel, Inconel, tantalum, titanium and several other metals are in common use where high pressure ratings and specific chemical compatibility are required. Flanged assemblies or flush welded versions are available. Depending on the PSI levels of the sealing application, the diaphragm may require fabr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyurethanes

Polyurethane (; often abbreviated PUR and PU) refers to a class of polymers composed of organic units joined by carbamate (urethane) links. In contrast to other common polymers such as polyethylene and polystyrene, polyurethane is produced from a wide range of starting materials. This chemical variety produces polyurethanes with different chemical structures leading to many different applications. These include rigid and flexible foams, varnishes and coatings, adhesives, electrical potting compounds, and fibers such as spandex and PUL. Foams are the largest application accounting for 67% of all polyurethane produced in 2016. A polyurethane is typically produced by reacting an isocyanate with a polyol. Since a polyurethane contains two types of monomers, which polymerize one after the other, they are classed as alternating copolymers. Both the isocyanates and polyols used to make a polyurethane contain two or more functional groups per molecule. Global production in 2019 wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hypalon

Hypalon is a chlorosulfonated polyethylene (CSPE) synthetic rubber (CSM) noted for its resistance to chemicals, temperature extremes, and ultraviolet light. It was a product of DuPont Performance Elastomers, a subsidiary of DuPont. Hypalon as it is now known in the marine industry today is a remarketed version of the old Hypalon using an additional layer of neoprene (cr) so the new chemical formulation is csm/cr. Chemical structure Polyethylene is treated with a mixture of chlorine and sulfur dioxide under UV-radiation. The product contains 20-40% chlorine. The polymer also contains a few percent chlorosulfonyl (ClSO2-) groups. These reactive groups allow for vulcanization, which strongly affects the physical durability of the products. An estimated 110,000 tons/y were produced in 1991. Discontinuance DuPont Performance Elastomers announced on May 7, 2009, that it intended to close its manufacturing plant in Beaumont, Texas Beaumont is a coastal city in the U.S. state of Tex ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicone Rubber

Silicone rubber is an elastomer (rubber-like material) composed of silicone—itself a polymer—containing silicon together with carbon, hydrogen, and oxygen. Silicone rubbers are widely used in industry, and there are multiple formulations. Silicone rubbers are often one- or two-part polymers, and may contain fillers to improve properties or reduce cost. Silicone rubber is generally non-reactive, stable, and resistant to extreme environments and temperatures from while still maintaining its useful properties. Due to these properties and its ease of manufacturing and shaping, silicone rubber can be found in a wide variety of products, including voltage line insulators; automotive applications; cooking, baking, and food storage products; apparel such as undergarments, sportswear, and footwear; electronics; medical devices and implants; and in home repair and hardware, in products such as silicone sealants. Curing In its uncured state, silicone rubber is a highly adhesive ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Neoprene

Neoprene (also polychloroprene) is a family of synthetic rubbers that are produced by polymerization of chloroprene.Werner Obrecht, Jean-Pierre Lambert, Michael Happ, Christiane Oppenheimer-Stix, John Dunn and Ralf Krüger "Rubber, 4. Emulsion Rubbers" in Ullmann's Encyclopedia of Industrial Chemistry, 2012, Wiley-VCH, Weinheim. Neoprene exhibits good chemical stability and maintains flexibility over a wide temperature range. Neoprene is sold either as solid rubber or in latex form and is used in a wide variety of commercial applications, such as laptop sleeves, orthopaedic braces (wrist, knee, etc.), electrical insulation, liquid and sheet-applied elastomeric membranes or flashings, and automotive fan belts. Production Neoprene is produced by free-radical polymerization of chloroprene. In commercial production, this polymer is prepared by free radical emulsion polymerization. Polymerization is initiated using potassium persulfate. Bifunctional nucleophiles, metal oxides (e.g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polychloroprene

Neoprene (also polychloroprene) is a family of synthetic rubbers that are produced by polymerization of chloroprene.Werner Obrecht, Jean-Pierre Lambert, Michael Happ, Christiane Oppenheimer-Stix, John Dunn and Ralf Krüger "Rubber, 4. Emulsion Rubbers" in Ullmann's Encyclopedia of Industrial Chemistry, 2012, Wiley-VCH, Weinheim. Neoprene exhibits good chemical stability and maintains flexibility over a wide temperature range. Neoprene is sold either as solid rubber or in latex form and is used in a wide variety of commercial applications, such as laptop sleeves, orthopaedic braces (wrist, knee, etc.), electrical insulation, liquid and sheet-applied elastomeric membranes or flashings, and automotive fan belts. Production Neoprene is produced by free-radical polymerization of chloroprene. In commercial production, this polymer is prepared by free radical emulsion polymerization. Polymerization is initiated using potassium persulfate. Bifunctional nucleophiles, metal oxides (e.g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |