|

National Board Of Boiler And Pressure Vessel Inspectors

The National Board of Boiler and Pressure Vessel Inspectors (NBBI) is composed of chief boiler and pressure vessel inspectors representing states, cities, and provinces enforcing pressure equipment laws and regulations. Created to prevent death, injury and destruction, these laws and regulations represent the collective input of National Board members. During the past ten years, over six million pressure equipment inspections were performed in North America. Of that total, there were more than 556,000 violations, or more than 556,000 potential accidents that were prevented: almost one out of every ten pieces of equipment inspected. For the general public, the importance of thoroughly trained and specially commissioned inspectors is of critical significance: every person in the civilized world comes within close proximity of pressure equipment several times each day. A Short History Steam drove the Industrial Revolution during the mid-19th century. At this point in history, conve ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam

Steam is a substance containing water in the gas phase, and sometimes also an aerosol of liquid water droplets, or air. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization. Steam that is saturated or superheated is invisible; however, "steam" often refers to wet steam, the visible mist or aerosol of water droplets formed as water vapor condenses. Water increases in volume by 1,700 times at standard temperature and pressure; this change in volume can be converted into mechanical work by steam engines such as reciprocating piston type engines and steam turbines, which are a sub-group of steam engines. Piston type steam engines played a central role in the Industrial Revolution and modern steam turbines are used to generate more than 80% of the world's electricity. If liquid water comes in contact with a very hot surface or depressurizes quickly below its vapor pressure, it can create a steam explosion. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going from hand production methods to machines, new chemical manufacturing and iron production processes, the increasing use of steam power and water power, the development of machine tools and the rise of the mechanized factory system. Output greatly increased, and a result was an unprecedented rise in population and in the rate of population growth. Textiles were the dominant industry of the Industrial Revolution in terms of employment, value of output and capital invested. The textile industry was also the first to use modern production methods. The Industrial Revolution began in Great Britain, and many of the technological and architectural innovations were of British origin. By the mid-18th century, Britain was the world's leadi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation. Heat sources In a fossil fuel power plant using a steam cycle for power generation, the primary heat source will be combustion of coal, oil, or natural gas. In some cases byproduct fuel such as the carbon monoxide rich offgasses of a coke battery can be burned to heat a boiler; biofuels such as bagasse, where economically available, can also be used. In a nuclear power plant, boilers called steam generators are heated by the heat produced by nuclear fission. Where a large volume of hot gas is available from some process, a heat recovery steam generator or recovery boiler can use the heat to produce steam, with little or no extra fuel consumed; such a configuration is common ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

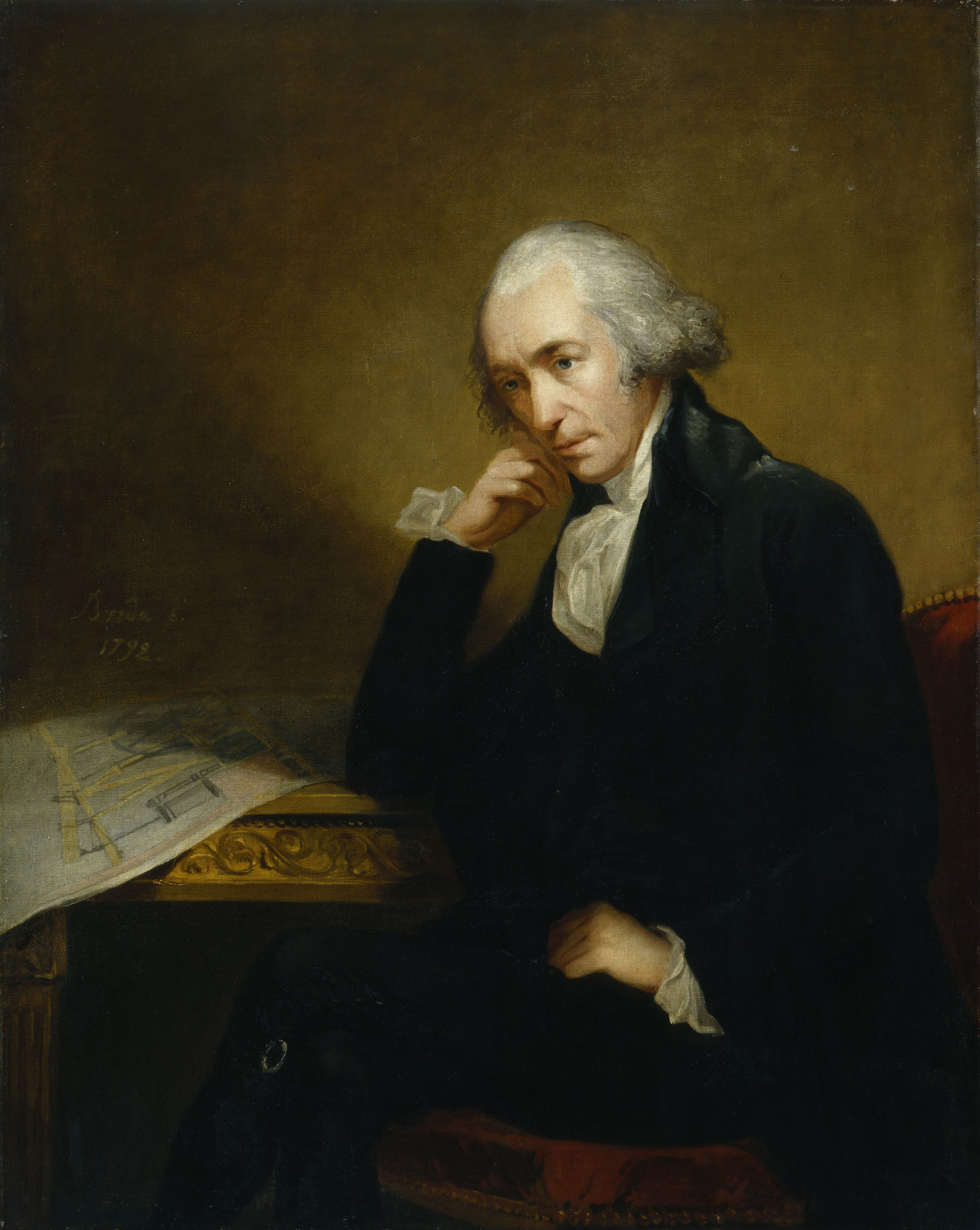

American Society Of Mechanical Engineers

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing education, training and professional development, codes and standards, research, conferences and publications, government relations, and other forms of outreach." ASME is thus an engineering society, a standards organization, a research and development organization, an advocacy organization, a provider of training and education, and a nonprofit organization. Founded as an engineering society focused on mechanical engineering in North America, ASME is today multidisciplinary and global. ASME has over 85,000 members in more than 135 countries worldwide. ASME was founded in 1880 by Alexander Lyman Holley, Henry Rossiter Worthington, John Edison Sweet and Matthias N. Forney in response to numerous steam boiler pressure vessel failures. Kno ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boiler Explosion

A boiler explosion is a catastrophic failure of a boiler. There are two types of boiler explosions. One type is a failure of the pressure parts of the steam and water sides. There can be many different causes, such as failure of the safety valve, corrosion of critical parts of the boiler, or low water level. Corrosion along the edges of lap joints was a common cause of early boiler explosions. The second kind is a fuel/air explosion in the furnace, which would more properly be termed a firebox explosion. Firebox explosions in solid-fuel-fired boilers are rare, but firebox explosions in gas or oil-fired boilers are still a potential hazard. Causes There are many causes for boiler explosions such as poor water treatment causing scaling and over heating of the plates, low water level, a stuck safety valve, or even a furnace explosion that in turn, if severe enough, can cause a boiler explosion. Poor operator training resulting in neglect or other mishandling of the boiler has be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ASME Boiler And Pressure Vessel Code (BPVC)

The ASME Boiler & Pressure Vessel Code (BPVC) is an American Society of Mechanical Engineers (ASME) standard that regulates the design and construction of boilers and pressure vessels. The document is written and maintained by volunteers chosen for their technical expertise . The ASME works as an accreditation body and entitles independent third parties (such as verification, testing and certification agencies) to inspect and ensure compliance to the BPVC. History The BPVC was created in response to public outcry after several serious explosions in the state of Massachusetts. A fire-tube boiler exploded at the Grover Shoe Factory in Brockton, Massachusetts, on March 20, 1905, which resulted in the deaths of 58 people and injured 150. Then on December 6, 1906, a boiler in the factory of the P.J. Harney Shoe Company exploded in Lynn, Massachusetts. As a result, the state of Massachusetts enacted the first legal code based on ASME's rules for the construction of steam boilers in 1907. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Construction methods and materials may be chosen to suit the pressure application, and will depend on the size of the vessel, the contents, working pressure, mass constraints, and the number of items required. Pressure vessels can be dangerous, and fatal accidents have occurred in the history of their development and operation. Consequently, pressure vessel design, manufacture, and operation are regulated by engineering authorities backed by legislation. For these reasons, the definition of a pressure vessel varies from country to country. Design involves parameters such as maximum safe operating pressure and temperature, safety factor, corrosion allowance and minimum design temperature (for brittle fracture). Construction is tested using nondestructive testing, such as ultrasonic testing, radiography, and pressure tests. Hydrostatic pressure tests ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Water Heating

Water heating is a heat transfer process that uses an energy source to heat water above its initial temperature. Typical domestic uses of hot water include cooking, cleaning, bathing, and space heating. In industry, hot water and water heated to steam have many uses. Domestically, water is traditionally heated in vessels known as ''water heaters'', ''kettles'', ''cauldrons'', ''pots'', or ''coppers''. These metal vessels that heat a batch of water do not produce a continual supply of heated water at a preset temperature. Rarely, hot water occurs naturally, usually from natural hot springs. The temperature varies with the consumption rate, becoming cooler as flow increases. Appliances that provide a continual supply of hot water are called ''water heaters'', ''hot water heaters'', ''hot water tanks'', ''boilers'', ''heat exchangers'', ''geysers'' (Southern Africa and the Arab world), or ''calorifiers''. These names depend on region, and whether they heat potable or non-potable w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nitroglycerin

Nitroglycerin (NG), (alternative spelling of nitroglycerine) also known as trinitroglycerin (TNG), nitro, glyceryl trinitrate (GTN), or 1,2,3-trinitroxypropane, is a dense, colorless, oily, explosive liquid most commonly produced by nitrating glycerol with white fuming nitric acid under conditions appropriate to the formation of the nitric acid ester. Chemically, the substance is an organic nitrate compound rather than a nitro compound, but the traditional name is retained. Invented in 1847 by Ascanio Sobrero, nitroglycerin has been used ever since as an active ingredient in the manufacture of explosives, namely dynamite, and as such it is employed in the construction, demolition, and mining industries. Since the 1880s, it has been used by militaries as an active ingredient and gelatinizer for nitrocellulose in some solid propellants such as cordite and ballistite. It is a major component in double-based smokeless propellants used by reloaders. Combined with nitrocellulose, hund ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Columbus, Ohio

Columbus () is the state capital and the most populous city in the U.S. state of Ohio. With a 2020 census population of 905,748, it is the 14th-most populous city in the U.S., the second-most populous city in the Midwest, after Chicago, and the third-most populous state capital. Columbus is the county seat of Franklin County; it also extends into Delaware and Fairfield counties. It is the core city of the Columbus metropolitan area, which encompasses 10 counties in central Ohio. The metropolitan area had a population of 2,138,926 in 2020, making it the largest entirely in Ohio and 32nd-largest in the U.S. Columbus originated as numerous Native American settlements on the banks of the Scioto River. Franklinton, now a city neighborhood, was the first European settlement, laid out in 1797. The city was founded in 1812 at the confluence of the Scioto and Olentangy rivers, and laid out to become the state capital. The city was named for Italian explorer Christopher Columbus. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Relief Valve

A relief valve or pressure relief valve (PRV) is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or equipment failure, or fire. The pressure is relieved by allowing the pressurized fluid to flow from an auxiliary passage out of the system. The relief valve is designed or set to open at a predetermined set pressure to protect pressure vessels and other equipment from being subjected to pressures that exceed their design limits. When the set pressure is exceeded, the relief valve becomes the "path of least resistance" as the valve is forced open and a portion of the fluid is diverted through the auxiliary route. In systems containing flammable fluids, the diverted fluid (liquid, gas or liquid-gas mixture) is either recaptured by a low pressure, high-flow vapor recovery system or is routed through a piping system known as a ''flare header'' or ''relief header'' to a central, elevated ga ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Safety Valve

A safety valve is a valve that acts as a fail-safe. An example of safety valve is a pressure relief valve (PRV), which automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds preset limits. Pilot-operated relief valves are a specialized type of pressure safety valve. A leak tight, lower cost, single emergency use option would be a rupture disk. Safety valves were first developed for use on steam boilers during the Industrial Revolution. Early boilers operating without them were prone to explosion unless carefully operated. Vacuum safety valves (or combined pressure/vacuum safety valves) are used to prevent a tank from collapsing while it is being emptied, or when cold rinse water is used after hot CIP (clean-in-place) or SIP (sterilization-in-place) procedures. When sizing a vacuum safety valve, the calculation method is not defined in any norm, particularly in the hot CIP / cold water scenario, but some manu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_pg328_AMERICAN_SOCIETY_OF_MECHANICAL_ENGINEERS._12_WEST_31ST_STREET.jpg)